Food Antifoaming Agents Market: Trends, Growth Drivers, and Future Outlook

The food and beverage industry has undergone a remarkable transformation over the last decade, driven by evolving consumer preferences, technological advancements, and stringent quality regulations. Among the many additives that play a crucial role in maintaining food quality and production efficiency, food antifoaming agents stand out for their importance in ensuring smooth manufacturing processes and product consistency.

As the global demand for processed foods, beverages, and dairy products continues to expand, the Food Antifoaming Agents Market is experiencing steady growth. These agents, commonly known as defoamers, are vital in controlling and eliminating foam formation during food processing — a key factor in maintaining production efficiency and product integrity.

Understanding Food Antifoaming Agents

Antifoaming agents are chemical additives designed to reduce and prevent foam formation in industrial processes. In food manufacturing, excessive foam can interfere with mixing, filling, and packaging operations, leading to inefficiencies, contamination risks, and inconsistent product texture or volume.

These agents function by destabilizing foam bubbles, allowing trapped air to escape quickly. They are used in a wide range of food applications, from dairy and beverages to oils, fats, and bakery products. Food-grade antifoaming agents are carefully formulated to comply with regulatory standards for safety, purity, and efficacy.

Market Overview and Growth Drivers

Several factors are fueling the growth of the food antifoaming agents market. The increasing consumption of processed foods, rising awareness of product quality, and growing investments in advanced food processing technologies are major contributors. Additionally, as global production scales up to meet the demands of urban populations, manufacturers are focusing on efficiency and cost reduction — both of which are supported by antifoaming solutions.

Regulatory compliance also plays a key role in shaping market trends. Agencies across regions have established clear guidelines for the use of food additives, including antifoaming agents. This has encouraged manufacturers to innovate and develop formulations that are both effective and safe for human consumption.

Sustainability is another emerging trend influencing market dynamics. Producers are increasingly exploring eco-friendly, plant-based, and biodegradable defoamers to meet consumer demand for clean-label and environmentally responsible ingredients.

Market Segmentation by Type

The market for food antifoaming agents can be broadly classified into oil-based, silicone-based, water-based, and other formulations. Each type offers distinct benefits depending on the food application and processing conditions.

1. Oil-Based Antifoaming Agents

Oil-based agents are among the traditional formulations used in food processing. They typically contain natural or mineral oils and hydrophobic particles that help reduce surface tension and eliminate foam. These agents are favored for their cost-effectiveness and wide compatibility with various food systems, particularly in cooking oils, frying, and fats processing.

2. Silicone-Based Antifoaming Agents

Silicone-based antifoaming agents are widely used due to their high efficiency at very low concentrations. They consist of silicone oils combined with hydrophobic silica, which provides superior foam suppression even under challenging processing conditions. Their thermal stability and resistance to degradation make them suitable for applications such as beverage manufacturing, dairy processing, and fermentation-based foods.

3. Water-Based Antifoaming Agents

Water-based antifoaming agents have gained popularity for their environmental benefits and ease of use. They are typically formulated with emulsified oils and surfactants in a water carrier, offering a safer and cleaner alternative for food applications that require minimal residue. These agents are ideal for aqueous systems such as soft drinks, fruit juices, and other liquid-based food products.

4. Others

The “others” category includes a range of specialized formulations that incorporate natural or bio-based materials. These are often developed for niche markets where clean-label and organic certification are key considerations. Innovations in this segment are growing rapidly as manufacturers align with sustainability trends and consumer preference for natural additives.

Market Segmentation by Application

Food antifoaming agents serve a wide range of applications within the food and beverage industry. Each segment has unique requirements in terms of stability, compatibility, and regulatory compliance.

1. Bakery and Confectionery

In bakery and confectionery production, foam control is crucial for achieving consistent texture, volume, and taste. Antifoaming agents are used in dough mixing, batter preparation, and syrup production to maintain uniformity and prevent unwanted aeration. They also help ensure smoother processing in candy making, where excessive foaming can affect product shape and quality.

2. Dairy and Frozen Desserts

The dairy sector is one of the most significant consumers of antifoaming agents. Foam formation during pasteurization, fermentation, and mixing can cause inefficiencies and affect final product consistency. In ice creams, yogurts, and cheese production, controlled foam reduction ensures better texture and mouthfeel. Food-grade silicone-based antifoams are particularly popular in this segment for their safety and performance.

3. Oils and Fats

In the production of edible oils, margarine, and fats, foaming can interfere with purification and refining processes. Antifoaming agents help maintain process efficiency by reducing foam during degumming, bleaching, and deodorization. They also prevent carryover losses and ensure higher product yield.

4. Beverages

The beverage industry relies heavily on antifoaming solutions, especially during bottling and fermentation processes. In soft drinks, beers, juices, and plant-based beverages, foam control is critical to avoid spillage, improve filling efficiency, and maintain clarity. The growing popularity of functional beverages and plant-based drinks is expanding the scope for innovative antifoaming formulations tailored for this sector.

5. Others

Other applications include sauces, soups, ready-to-eat meals, and processed foods where foaming may disrupt production. Customized antifoaming agents are often used to meet specific formulation requirements while maintaining product stability and flavor integrity.

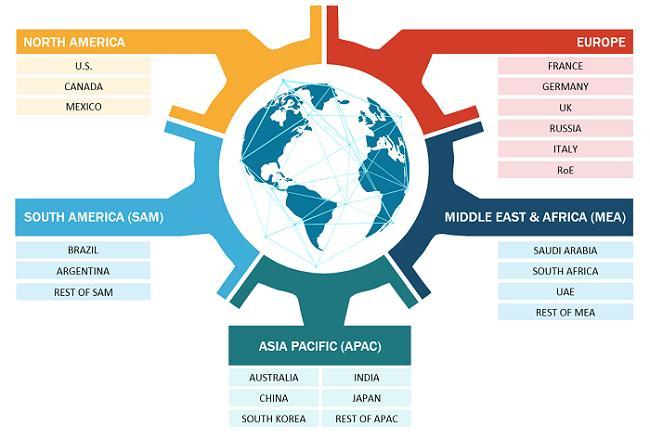

Geographical Analysis

1. North America

North America remains a leading market for food antifoaming agents, supported by a well-established food processing industry and stringent regulatory frameworks. The U.S. and Canada are major contributors, driven by high demand for convenience foods, beverages, and dairy products. Technological advancements and the presence of key market players further strengthen the region’s dominance.

2. Europe

Europe is another significant market, characterized by strong consumer awareness of food quality and safety. Regulatory bodies in the European Union impose strict guidelines on additive use, prompting manufacturers to invest in research and development for compliant, sustainable, and effective defoaming solutions. The region’s emphasis on organic and natural ingredients also creates opportunities for innovation.

3. Asia Pacific

The Asia Pacific region is experiencing rapid market growth due to the expansion of the food processing sector in countries such as China, India, Japan, and South Korea. Rising disposable incomes, urbanization, and changing dietary habits are driving demand for processed foods and beverages. Local manufacturers are increasingly adopting modern production technologies, fueling the need for efficient antifoaming agents.

4. South and Central America

South and Central America represent emerging markets with growing potential. The expanding food and beverage industry, coupled with increasing foreign investment, is supporting market development. Brazil, Argentina, and Mexico are key contributors, with significant opportunities in dairy, beverage, and edible oil processing.

Future Outlook

The future of the food antifoaming agents market lies in innovation, sustainability, and compliance. Manufacturers are focusing on developing natural, allergen-free, and biodegradable formulations to align with evolving consumer expectations and environmental standards. Moreover, advancements in nanotechnology and biotechnology are paving the way for next-generation antifoaming solutions with enhanced efficiency and minimal impact on product characteristics.

As the global food industry continues to expand and diversify, the demand for high-quality, safe, and effective processing aids will only intensify. Food antifoaming agents, with their indispensable role in maintaining operational efficiency and product excellence, will remain a vital component of this evolving landscape.

Conclusion:

The food antifoaming agents market is poised for sustained growth across regions and applications. Driven by innovation, regulatory evolution, and shifting consumer trends, the industry is moving toward more sustainable and performance-oriented solutions. Whether silicone-based, oil-based, or water-based, antifoaming agents will continue to play a pivotal role in shaping the future of modern food processing.

Also Available in :