Top-Quality Die Casing Die Solutions for Precision Manufacturing

Precision is the foundation of every successful manufacturing process, especially in industries like automotive, electronics, power tools and machinery parts. As demand for accuracy, speed and consistency increases, companies are constantly searching for tools that enhance production quality. One such essential tool that plays a major role in shaping metal components with high accuracy is the Die Casing Die. Modern industries rely on advanced die systems to achieve flawless casting results, reduce defects and produce parts that meet global standards.

High-quality die solutions are becoming a necessity, not a choice. In today’s competitive landscape, manufacturers look for long-lasting, heat-resistant and high-performance dies that eliminate production challenges. This is exactly where an advanced Die Casing Die system stands out as a smart investment for companies aiming for stable and efficient operations.

Understanding the Role of Die Casing Die in Manufacturing

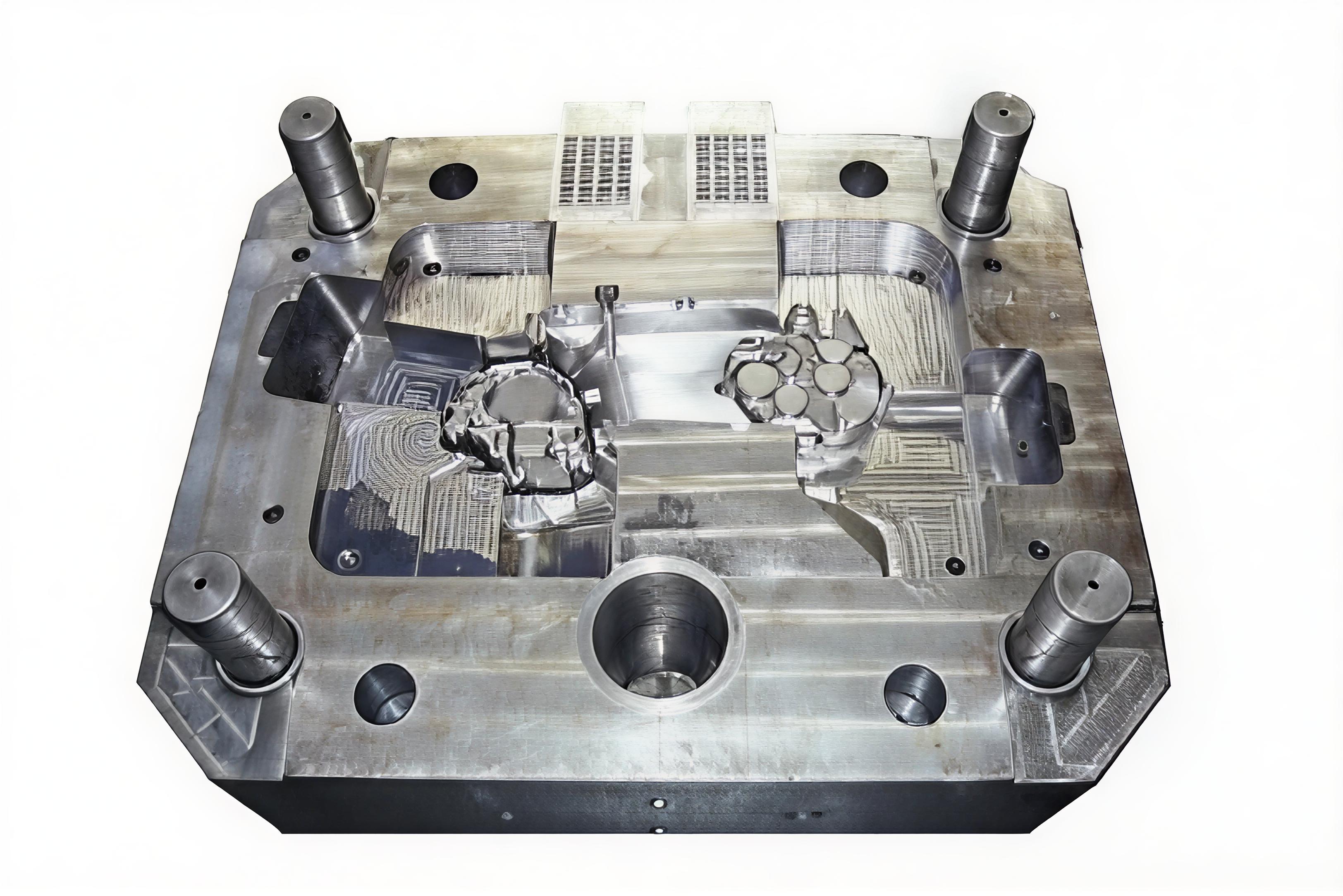

A Die Casing Die is a specially engineered tool used to shape molten metal into accurate, complex and defect-free components. It ensures uniformity, precision and repeatability in every production cycle. Whether the requirement is for small electronic housings or larger mechanical components, the die ensures consistent output during mass production.

Manufacturers prefer using high-grade dies because they reduce the chances of rework, minimize wastage and ensure stable quality throughout the process. A well-designed die can withstand high temperatures, heavy pressure and continuous operational load without losing its structural integrity. This makes it a reliable tool for industries where precision is critical.

Why Quality Matters in Die Casing Die Manufacturing

The performance of a casting process depends largely on the quality of the Die Casing Die used. A high-quality die ensures smooth metal flow, accurate cavity dimensions and better surface finishing of the final product. Poor-quality dies, on the other hand, can lead to casting defects, material shrinkage issues, inconsistent results and increased production downtime.

Premium-quality dies reduce maintenance requirements and offer longer service life. They also support modern automated casting systems where precision is mandatory. As industries move toward faster production cycles, the value of a durable and efficient die increases significantly.

A top-grade Die Casing Die also contributes to lowering production costs, as manufacturers can produce large quantities of components with minimal rejection rates. The better the die quality, the more efficient and profitable the manufacturing process becomes.

Advanced Technologies Improving Die Casing Die Design

With the rise of digital manufacturing, simulation software, CNC machining and tool steel advancements, the design of the Die Casing Die has evolved greatly. Modern dies are manufactured using high-quality steel alloys with exceptional heat resistance and structural strength.

Advanced machining techniques ensure the die cavity is shaped with a high degree of accuracy. This results in smoother internal surfaces, quicker metal flow and improved strength of finished parts. Such enhancements not only improve product quality but also extend the lifespan of the die itself.

Today, industries also prefer customized die solutions tailored to their unique product requirements. Companies like Auto Die Cast (India) have contributed to bringing modern die-making standards into the manufacturing sector, enabling faster development cycles and more reliable outcomes.

Benefits of Using a High-Performance Die Casing Die

A well-manufactured Die Casing Die offers multiple advantages for production teams. One of the biggest benefits is consistency. Precision dies ensure that every part produced matches the exact specifications required. This helps maintain brand reliability while reducing inspection time.

These dies are also designed for excellent heat dissipation, which prevents damage during long production runs. Better heat control leads to fewer cracks and longer operational life. With improved durability, manufacturers can run continuous cycles without frequent interruptions for die repairs or replacements.

Another benefit is enhanced dimensional accuracy. High-quality dies ensure that the final cast parts require minimal machining after production. This saves both time and resources, making the process cost-effective.

Companies that invest in robust die systems often experience smoother workflows and reduced defects. Even industries with strict quality standards benefit immensely from a reliable Die Casing Die that supports high-volume and high-precision production.

Choosing the Right Partner for Die Casing Die Solutions

Selecting the right die manufacturer is essential for achieving long-term production reliability. The ideal partner should have expertise in die design, engineering and testing. They must understand the material properties, thermal behavior and stress points that affect die performance.

Reputable companies offer detailed design analysis, testing procedures and accurate machining services to ensure the die performs flawlessly under high pressure and extreme temperature conditions. A trusted brand like Auto Die Cast (India) has been known for delivering highly durable dies that meet global industrial expectations.

When selecting a partner, manufacturers should also look for support in die maintenance, after-sales service and customization capabilities. A knowledgeable supplier not only delivers a quality product but also assists in optimizing its performance throughout the production cycle.

Conclusion

Precision manufacturing requires tools that deliver stability, accuracy and long-term reliability. A premium-grade Die Casing Die plays a vital role in shaping high-quality components and improving overall production efficiency. As industries move toward advanced technologies and automated systems, the need for reliable die solutions becomes even more important. Investing in high-performance dies ensures superior output, reduced defects and better profitability for manufacturers looking to stay ahead in the competitive global market. If you want to achieve better quality, higher speed and consistent production, contact us today and upgrade your manufacturing process with the right die solution.