Best Magnetic Separator Manufacturers for Material Handling

Material handling in most modern industrial operations involves the alignment of smooth processes, reduced downtimes, and product quality. Among the most helpful equipment to enhance material handling processes is the magnetic separator. These units efficiently clean bulk materials from ferrous contaminants, protecting machinery and improving product purity, while offering safety in operation. The search for the best magnetic separator manufacturer for handling materials is an issue of paramount importance to a business intending to operate within internationally set benchmarks on efficiency and reliability.

What are magnetic separators?

Magnetic separators are devices that separate magnetic materials from non-magnetic materials. In short, these essential usages of magnetic separators extend to many industries in mining, recycling, food processing, chemical manufacturing, and material handling. They protect machinery from damage by removing unwanted metal particles, reducing product contamination, and increasing efficiency.

These are the major types of separators:

-

Drum separators

-

Overband magnets

-

Pulley magnets

-

Plate magnets

Why Magnetic Separators Are Important to Material Handling

Material handling often involves transportation of raw materials, powders, grains, or bulk solids. In all these processes, metallic contaminants like iron, steel fragments, or metal dust may mix with the product. These might further lead to:

-

Damage to equipment and increased maintenance cost

-

Poorer quality of the product and safety issues

-

Downtime in production and financial losses

High-quality magnetic separators ensure that metals are effectively taken out to protect machinery and end products. Reliable Magnetic Separator Manufacturers provide support for better output, lower maintenance, and improved safety of industries.

Key Features of the Best Magnetic Separator Manufacturers

The proper selection of the manufacturer is crucial in ensuring quality, performance, and the longevity of magnetic separators. Some of the features that should be considered include:

1. Industry Experience

Companies involved in manufacturing bring with them years of experience in industry challenges. Solutions offered are specifically designed for effective material handling. Their expertise makes sure that separators meet particular operational needs.

2. Material Quality

Top manufacturers employ quality magnets, stainless steel bodies, and other durable components that will withstand harsh industrial environments, assuring a long life with minimum maintenance.

3. Personalization

Each industry is unique, so each industry has different needs. The better a manufacturer, the more options they will provide for custom design to suit a particular capacity, conveyor size, and type of material handled.

4. Conformance and Standards

Accomplished separators by reputed manufacturers assure that their products address the safety and efficiency concerns to set industrial standards. This can be in the form of a food-grade or industrial-grade certificate, depending on its use.

5. After-Sales Support

All good manufacturers ensure highly professional customer service: installation guidance, maintenance, and technical support are extremely important for continuing material handling.

Top Types of Magnetic Separators for Material Handling

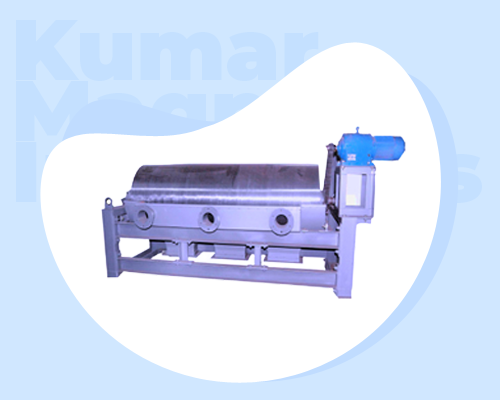

1. Magnetic Drum Separators

Drum separators are employed in the removal of ferrous contaminants from bulk materials, and as such, they find ideal applications in industries such as mining and recycling. They offer continuous operation and high separation efficiency.

2. Overband Magnets

These magnets are installed over the conveyor and efficiently separate tramp metal from moving materials. Overband magnets see a very wide application in the recycling and aggregate handling industries.

3. Pulley Magnets

Pulley magnets are mounted in conveyor systems and pull the ferrous metals off as the materials pass over. Relatively inexpensive, they also are pretty easy to maintain.

4. Plate Magnets

Plate magnets are used in the capture of metal contaminants in gravity-fed hoppers, chutes, and pipelines. They can be simple, efficient, and widely applied in food processing and chemical industries.

Why Choosing the Best Magnetic Separator Manufacturer Matters

Major investment in high-quality magnetic separators with reliable manufacturers ensures:

-

Productivity improves due to the efficiency in the removal of metallic contaminants that reduces downtime.

-

Machine Protection: Avoids potential deterioration of costly industrial equipment.

-

Product Quality: Ensuring the purity and safety of the final products.

-

Cost-effectiveness—It reduces the loss due to less maintenance and operational loss.

-

Longevity: Good-quality separators might endure, thus offering better ROI.

A reliable manufacturer, Kumar Magnet, one of the leading Magnetic Destoner Manufacturers, provides high-quality magnetic separators for heavy-duty industrial purposes that ensure high reliability, precision in engineering, and performance for years to come.

Identifying the Ideal Manufacturers for Your Needs

The following practical steps will help when looking for the best magnetic separator manufacturer in material handling:

1. Experience and Portfolio: Check out the long experience of the manufacturers in the line of supplying separators to the concerned industry.

2. Product Quality Assessment: Material review, magnet strength, durability.

3. Ability to Customize: This should mean that the manufacturer should be in a position to offer solutions with your specific needs in mind.

4. Customer reviews and references will also provide insight into the efficiency and reliability of the service.

5. Support and Service: Ensure timely after-sales support for installation, maintenance, and troubleshooting.

Benefits of partnering with reliable manufacturers

Now, associating with a well-reputed manufacturer has many advantages:

-

Expert recommendations on the choice of separator type appropriate for the application

-

Tailor-made solutions for your production line.

-

Access to quality materials and precision engineering

-

Reduced operational risks and increased efficiency.

Apart from superior products, these manufacturers assist their clients with installation, maintenance, and operational optimization to ensure maximum performance from your material handling system.

Conclusion

Efficient material handling is the backbone of any industrial operation, and magnetic separators are essentially important in maintaining quality, safety, and productivity. The best manufacturers of magnetic separators in material handling ensure reliability and high-performance solutions that protect machinery and ensure improvement in operational efficiency.

Reliable solutions are offered for industries seeking heavy-duty, high-quality magnetic separators that are precision-engineered to meet industrial needs. These separators ensure consistent performance, durability, and efficiency across various applications.

Take your material handling process to the next level today! Get in touch with Kumar Magnet for expert advice and a tailor-made solution with a magnetic separator.

Source URL: https://medium.com/@kumarmagnet86/best-magnetic-separator-manufacturers-for-material-handling-a5e86ed4b475