Can Understanding B10-5280 Improve Bearing Replacement Decisions?

In mechanical and automotive systems, bearings are identified not only by size and structure but also by original equipment numbers that help ensure compatibility. One such reference is B10-5280, an OE bearing number used to identify a specific bearing type within established assemblies. Understanding how this number functions within supply chains and maintenance practices helps engineers, distributors, and technicians communicate clearly and reduce selection errors.

The OE number B10-5280 serves as a standardized identifier rather than a descriptive model name. It allows manufacturers and service providers to trace the bearing back to its intended application without relying solely on measurements. This approach simplifies sourcing, particularly in industries where multiple bearing designs may appear similar but perform differently under load, speed, or temperature conditions. By using OE numbers, documentation remains consistent across production, installation, and servicing stages.

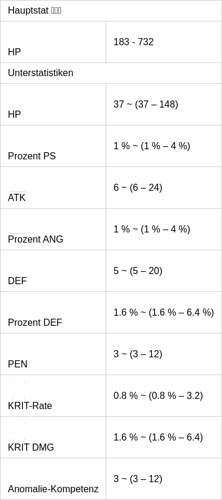

From a technical perspective, a bearing referenced as B10-5280 is designed to meet specific dimensional and performance requirements defined by the original equipment application. These requirements typically include inner and outer diameters, width, load capacity, and rotational characteristics. While alternative bearings may share comparable dimensions, the OE number confirms alignment with the original design intent, supporting predictable operation within the assembly.

Applications associated with B10-5280 are often found in automotive components where stable rotation and controlled friction are required. Such bearings may be used in drivetrain systems, auxiliary assemblies, or other rotating parts that operate continuously during vehicle use. In these environments, consistent bearing behavior supports smooth motion and helps limit wear on surrounding components. Selecting the correct OE-referenced bearing reduces the risk of noise, vibration, or premature failure.

When it comes to maintenance and repair, B10-5280 plays an important role in replacement decisions. Technicians frequently rely on OE numbers when servicing vehicles or machinery to ensure that replacement parts match the original configuration. Using the OE reference helps avoid mismatches that could arise from relying only on approximate dimensions or generic descriptions. This practice supports efficiency in workshops and reduces repeated adjustments during installation.

Quality assurance processes also reference identifiers such as B10-5280. Manufacturers and suppliers often test bearings according to specifications linked to the OE number, including material composition, surface finish, and rotational tolerance. These checks help confirm that the bearing performs within expected parameters when installed. Documentation tied to the OE number further supports traceability, which is important for inventory control and after-sales service.

In global supply networks, B10-5280 assists communication between different parties. Distributors, exporters, and procurement teams use OE numbers to align orders across regions where naming conventions may differ. This shared reference reduces ambiguity and supports smoother transactions, especially when sourcing bearings for maintenance programs or long-term supply contracts.

B10-5280 is more than a simple code; it is a practical reference that connects design intent, application requirements, and replacement accuracy. By understanding how OE bearing numbers function, professionals across manufacturing, maintenance, and distribution can make informed decisions and maintain system reliability. As mechanical systems continue to rely on precise component matching, OE identifiers like this one remain a valuable part of technical communication and operational clarity.

https://www.zjsybearing.com/product/tensioner-bearing/vkm26020-deflection-guide-pulley.html