The Future of Nanofiber Technology in Filtration

As global industries face rising concerns around air quality, water safety, and environmental sustainability, Nanofiber Technology is rapidly emerging as a transformative solution in filtration systems. From advanced air purification to high-performance water treatment, nanofibers are redefining how contaminants are captured, controlled, and eliminated. At Matregenix, innovation in nanomaterials continues to push the boundaries of what filtration technology can achieve.

Understanding Nanofiber Technology in Filtration

Nanofiber Technology involves fibers with diameters typically measured in nanometers, offering an exceptionally high surface-area-to-volume ratio. This unique structure enables nanofiber-based filters to trap even the smallest particles, including bacteria, viruses, fine dust, and toxic aerosols. Compared to conventional filtration media, nanofibers provide higher efficiency without significantly increasing airflow resistance or energy consumption.

In filtration applications, nanofibers are commonly produced using electrospinning techniques, allowing precise control over fiber diameter, porosity, and layer thickness. This level of customization makes Nanofiber Technology ideal for diverse filtration requirements across industries.

Why Nanofiber Technology Is the Future of Filtration

1. Superior Filtration Efficiency

One of the most significant advantages of Nanofiber Technology is its ability to capture ultra-fine particles. Nanofiber filters can efficiently remove PM2.5 and even PM0.3 particles, making them ideal for air purification in healthcare facilities, cleanrooms, and industrial environments. In water filtration, nanofibers enhance the removal of pathogens, heavy metals, and microplastics.

2. Improved Breathability and Flow Rates

Traditional high-efficiency filters often suffer from pressure drop issues. Nanofiber Technology overcomes this challenge by enabling high filtration performance while maintaining excellent airflow. This balance is critical for applications such as HVAC systems, respirators, and face masks, where comfort and efficiency must coexist.

3. Lightweight and Material-Efficient

Nanofiber-based filtration media are extremely lightweight and require less raw material compared to conventional filters. This not only reduces manufacturing costs but also supports sustainability goals by minimizing material waste an important focus for Matregenix and forward-thinking manufacturers worldwide.

Emerging Applications Shaping the Future

Advanced Air Filtration

As urban pollution and industrial emissions increase, demand for high-performance air filtration continues to grow. Nanofiber Technology is playing a pivotal role in next-generation air filters for smart buildings, electric vehicles, and personal protective equipment. Future systems will integrate nanofiber layers with sensors and AI-driven monitoring to optimize air quality in real time.

Water and Wastewater Treatment

Clean water scarcity is a global challenge, and Nanofiber Technology offers promising solutions. Nanofiber membranes enable efficient desalination, wastewater recycling, and point-of-use water purification. Their tunable pore sizes allow selective filtration, improving performance while reducing energy consumption.

Industrial and Chemical Filtration

Industries handling corrosive gases, solvents, and fine powders benefit greatly from nanofiber-enhanced filters. Future developments focus on functionalized nanofibers with antimicrobial, hydrophobic, or chemical-resistant properties, expanding their durability and application range.

Sustainability and Environmental Impact

The future of Nanofiber Technology in filtration is closely tied to sustainability. Researchers and manufacturers are increasingly exploring biodegradable and bio-based polymers for nanofiber production. These eco-friendly materials help reduce environmental impact without compromising filtration efficiency.

At Matregenix, sustainable innovation is a key driver. By optimizing nanofiber structures and manufacturing processes, the company aims to deliver filtration solutions that are not only high-performing but also environmentally responsible.

Challenges and Future Innovations

Despite its promise, Nanofiber Technology still faces challenges, including large-scale manufacturing consistency and long-term durability in harsh environments. However, continuous advancements in automation, AI-assisted quality control, and hybrid material systems are rapidly addressing these limitations.

Looking ahead, the integration of Nanofiber Technology with smart filtration systems, self-cleaning surfaces, and multifunctional coatings will further revolutionize the filtration industry. These innovations will enable longer filter lifespans, lower maintenance costs, and enhanced performance across applications.

Conclusion

The future of filtration lies in smarter, more efficient, and more sustainable solutions and Nanofiber Technology is at the heart of this transformation. With unmatched filtration efficiency, adaptability, and environmental benefits, nanofibers are setting new standards in air, water, and industrial filtration. As a leader in advanced material innovation, Matregenix continues to shape the next generation of filtration technologies, helping industries and communities breathe cleaner air and access safer water worldwide.

Categorie

Leggi tutto

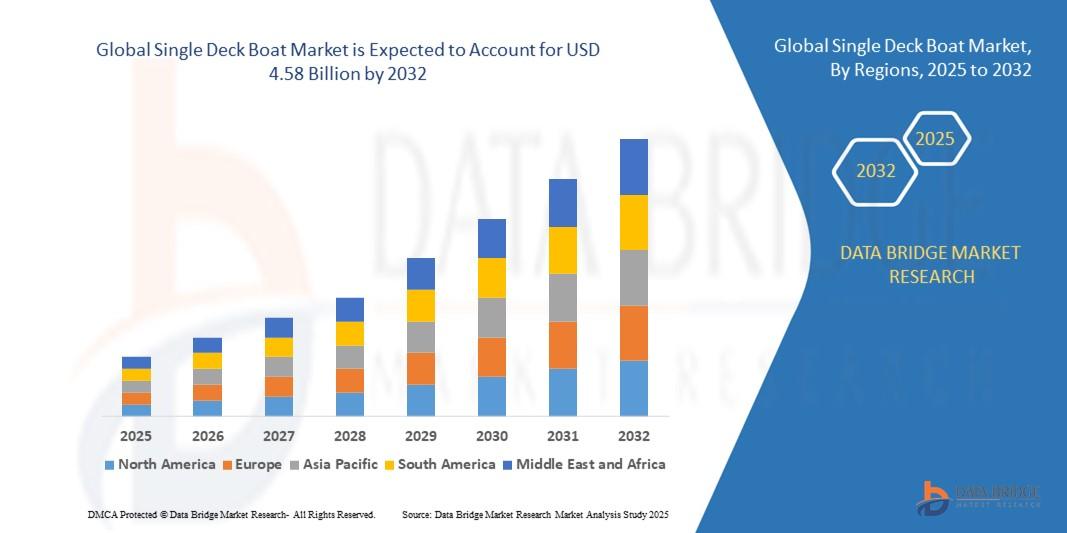

"Regional Overview of Executive Summary Single Deck Boat Market by Size and Share The global single deck boat market size was valued at USD 2.76 billion in 2024 and is expected to reach USD 4.58 billion by 2032, at a CAGR of 6.50% during the forecast period With the superior Single Deck Boat Market report, get knowledge about the industry which...

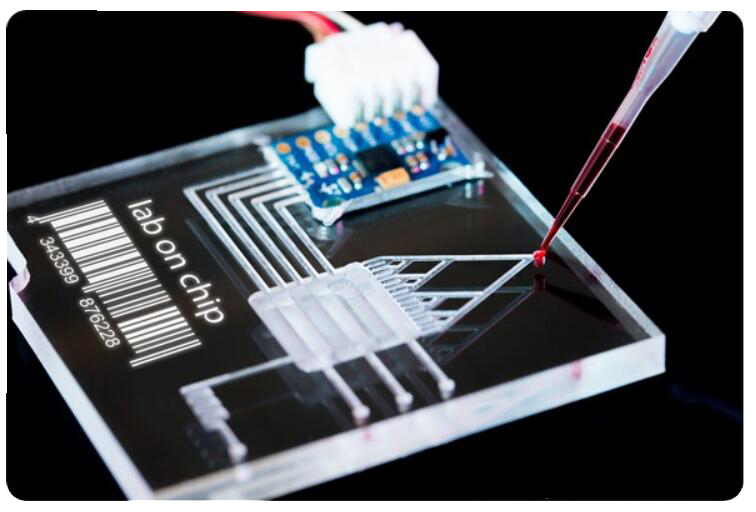

Flow cytometry has long been a cornerstone of biomedical research, enabling scientists to analyze thousands of cells in real time. From immune profiling to drug discovery, it provides a window into cellular diversity and function. Yet, as powerful as traditional cytometers are, they can be bulky, resource-intensive, and limited in flexibility. Enter microfluidics—a field that is quietly...

Benefits of Using Certification Exam Preparation Material Certification exams help people grow in their careers. They help you get better jobs. They also help you earn more money. Many students want to pass the PSM-II exam on the first attempt. This exam is offered by Scrum. However, exam preparation can feel difficult. There are many books to read and many topics to cover. This is why using...

Executive Summary Automotive Collision Repair Market : The global automotive collision repair market size was valued at USD 60.90 billion in 2024 and is projected to reach USD 86.40 billion by 2032, with a CAGR of 4.47% during the forecast period of 2025 to 2032. Today’s businesses choose the market research report solution such as Automotive Collision Repair Market report...

Refraction testing has long been a cornerstone of ophthalmology, forming the basis for diagnosing visual errors and prescribing corrective lenses. Traditionally, this process relied heavily on manual techniques and patient feedback. While effective, these methods often required extended examination times and were influenced by subjective responses. As patient volumes increased and expectations...