How Aircraft Cabinet Latches Support Aviation Safety and Compliance

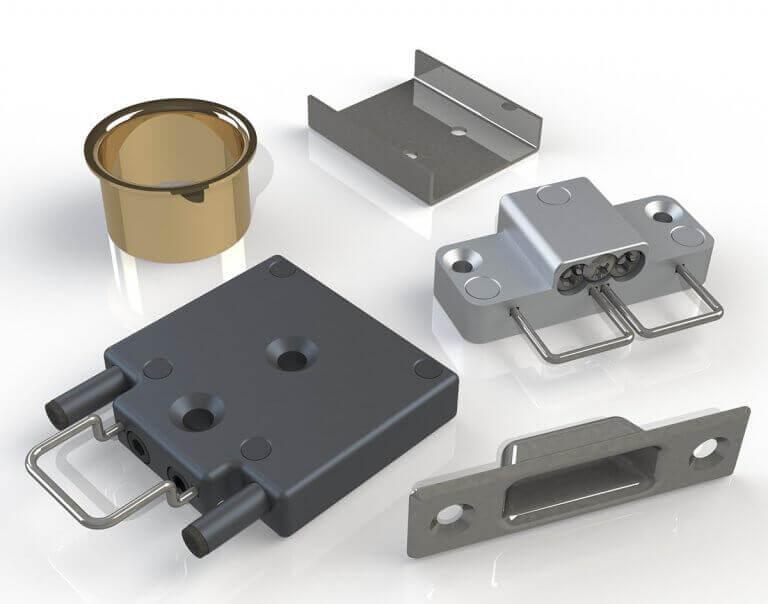

In today’s aircraft, it is highly important to have a secure closure of the interior compartments, and the role of aircraft cabinet latches is very significant for this purpose. Aircraft cabinet latches are designed to close the storage compartments, galley compartments, and other interior compartments to ensure safe aircraft performance. These latches do not allow unintended openings due to turbulence, vibration, or changes in the aircraft cabin pressure, which may pose a threat to airline passengers.

These may include the use of durability as well as precision in the designs of the latches. These materials may include stainless steel, aluminum alloys, as well as high strength polymers that may be used as a result of the need for the ability to withstand being used repeatedly as well as environmental conditions such as humidity and temperature variation. Engineers may make use of light weight designs for the purpose of minimizing the weight of the aircraft.

The aviation industry has tight requirements for aircraft cabinet latches. In the USA, for example, aviation regulators demand that all cabin fittings comply with certain certification requirements to work well in extreme conditions. This includes requirements for testing their strength under loads, endurance testing, as well as tests for resistance to wear and corrosion. This ensures that all components last well in their lifetime to work properly by reducing maintenance costs.

Types of mechanism used will differ depending on the purpose of use. Examples of push-to-close, rotary, and toggle latches mean that each type has its own benefits to offer. While push-to-close catches guarantee a one-motion closure mechanism to keep compartments sealed, rotary and toggle catches can provide additional security by way of locks or protection from vibration.

Maintenance and checks on such mechanisms are also crucial. Regular inspections find the onset of wear, misalignment, or corrosion before performance can be compromised. Cabin crew members are sometimes trained in recognizing operational problems, and maintenance teams follow detailed schedules for replacement or adjustment of components as needed. Proper maintenance ensures interior compartments continue to safely and efficiently execute their functions, supporting overall flight operations.

Besides functional aspects, latches selection incorporates aesthetic considerations. Many designs are streamlined to integrate easily into cabin interiors, providing a clean and professional appearance. Attention to detail in finish and texture adds not only to passenger experience but also to the practical operation of storage units and service areas.

Ultimately, it is through engineering capabilities, materials, regulatory requirements, and maintenance processes that airplane interior safety, organization, and functionality are achieved and assured. The role of these critical but minutest components is not least in its importance, as it has a direct role in air safety and functionality. The role and importance of good fasteners in the aviation sector have not gone without being noticed by people in the aviation sector.