Ball Bearing Market Share Insights Highlighting Leading Manufacturers and Global Supply Trends

As Per Market Research Future, the Ball Bearing Market Share is becoming increasingly competitive, with key players focusing on innovation and strategic partnerships to capture a larger share. The dynamics of market share are influenced by factors such as technological advancements, regional developments, and product differentiation. Leading manufacturers are investing in marketing strategies and enhancing their product offerings to attract more customers across various applications. As the demand for ball bearings continues to rise, companies that prioritize customer satisfaction and operational efficiency will likely gain a competitive edge in the market.

The Ball Bearing Market is a fundamental component of global industrial manufacturing and machinery sectors. Ball bearings, essential for reducing friction and supporting rotational movement, are widely used in automotive, aerospace, construction, and industrial machinery applications. The market is growing steadily due to increasing industrialization, technological innovations in bearing materials, and rising demand from automotive and renewable energy sectors.

Market Overview

Ball bearings are designed to support axial and radial loads while enabling smooth motion in mechanical systems. These bearings are critical for improving operational efficiency, reducing wear and tear, and enhancing machinery lifespan. Advances in precision engineering and the use of high-quality materials such as stainless steel, ceramic, and hybrid composites are driving the adoption of ball bearings in various high-performance applications.

Key Market Drivers

The growth of the ball bearing market is driven by industrial expansion, rising automotive production, and increasing adoption of renewable energy technologies such as wind turbines. The automotive sector remains a key end-user, as bearings are essential for engines, transmissions, and wheel assemblies. Additionally, the industrial automation trend has increased demand for high-precision and durable ball bearings, supporting machinery and robotics operations globally.

Technological Advancements

Modern ball bearings are witnessing innovations in materials, lubrication technologies, and design. Hybrid ball bearings combining steel races with ceramic balls offer high-speed performance and reduced weight. Self-lubricating and maintenance-free bearings reduce downtime and operational costs, making them ideal for automotive and industrial applications. Moreover, smart bearings equipped with sensors for vibration and temperature monitoring are gaining traction for predictive maintenance and IoT-enabled machinery.

Market Segmentation

The market can be segmented by type, material, and end-use industry. Ball bearing types include deep groove, angular contact, thrust, and self-aligning bearings. Materials used include stainless steel, ceramic, and hybrid composites. Key end-use industries include automotive, aerospace, industrial machinery, construction equipment, and energy generation, reflecting the diverse applications of ball bearings across sectors.

Regional Insights

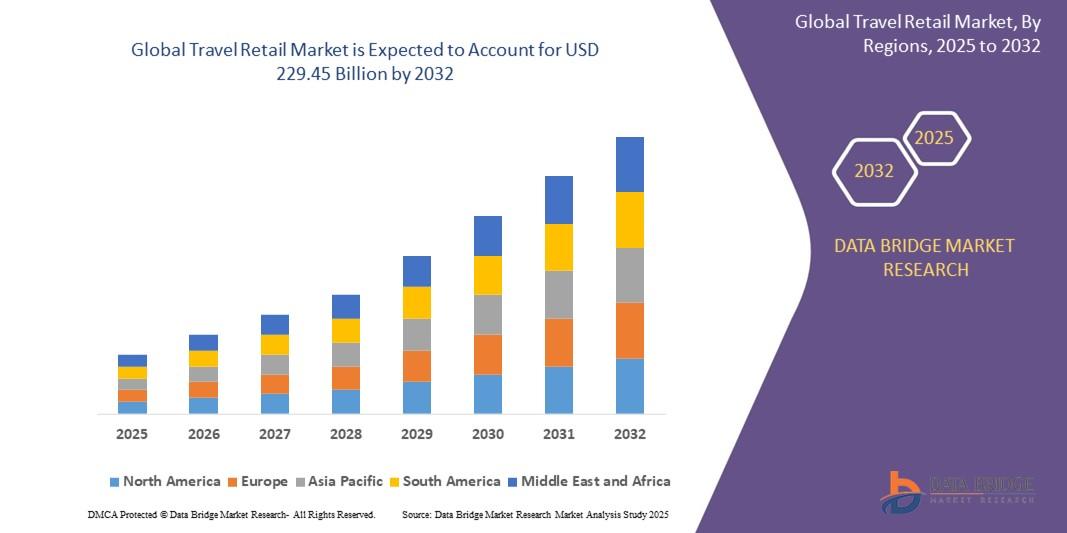

Asia-Pacific dominates the ball bearing market, driven by manufacturing hubs in China, India, and Japan. The region benefits from large-scale automotive production, industrial machinery demand, and infrastructure growth. North America and Europe maintain significant market shares due to advanced manufacturing, precision engineering, and high adoption of smart bearing technologies. Emerging markets in Latin America and the Middle East are showing growth potential due to industrialization and infrastructure development.

Challenges and Opportunities

Challenges in the ball bearing market include fluctuating raw material prices, intense competition, and the need for high-precision manufacturing capabilities. However, opportunities lie in the development of hybrid and smart bearings, expansion in renewable energy sectors, and increasing adoption in robotics and industrial automation. Strategic partnerships and product innovations can drive market growth and differentiate players in a competitive landscape.

Conclusion

The Ball Bearing Market continues to grow, fueled by industrial automation, automotive demand, and technological innovation in materials and design. As industries increasingly adopt smart manufacturing and predictive maintenance solutions, ball bearings will play a critical role in enhancing operational efficiency and machinery performance. The market is poised for sustained growth, particularly in regions experiencing rapid industrialization.

FAQs

Q1: What are the main types of ball bearings?

Deep groove, angular contact, thrust, and self-aligning bearings are common types used in various applications.

Q2: Which industries use the most ball bearings?

Automotive, industrial machinery, aerospace, construction, and renewable energy industries are major users.

Q3: What are hybrid ball bearings?

Hybrid ball bearings combine steel races with ceramic balls, offering high-speed performance, reduced weight, and durability.