Revolutionizing Manufacturing: How Le-Leaser Leads the Way in Laser Integrated Processing

In today’s fast-paced manufacturing world, efficiency, precision, and adaptability are more critical than ever. Companies are constantly searching for innovative solutions that can deliver high-quality results while reducing waste and operational costs. This is where laser integrated processing comes into play, and Le-Leaser is at the forefront of this technological revolution.

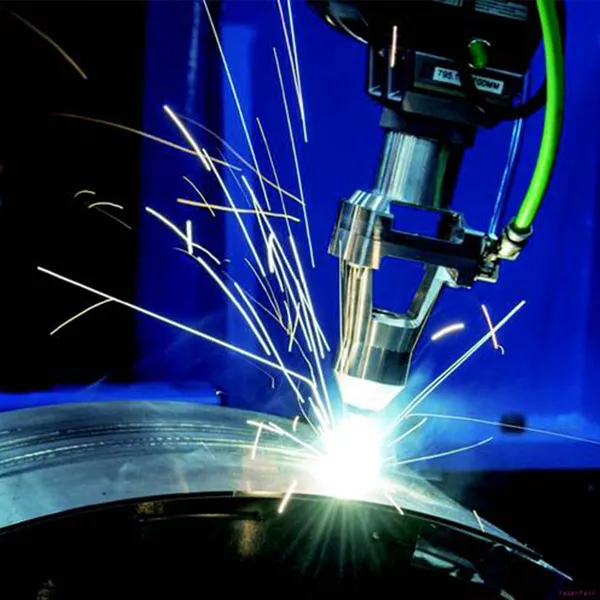

Laser integrated processing combines the power of laser technology with traditional manufacturing processes, enabling businesses to achieve unmatched accuracy and speed. Unlike conventional methods, lasers can perform cutting, welding, engraving, and surface treatment in a single, integrated system. This not only reduces the time spent on multiple steps but also minimizes errors, material wastage, and post-processing requirements.

Le-Leaser has harnessed this technology to develop advanced solutions that cater to diverse industries, from automotive and aerospace to electronics and medical devices. One of the standout features of Le-Leaser’s laser integrated systems is their precision control. These systems are designed with highly sophisticated software that allows operators to customize laser parameters for different materials and thicknesses. The result is a flawless finish and reliable performance, even on complex components that are difficult to process using conventional machinery.

Another major advantage of Le-Leaser’s solutions is efficiency and scalability. Businesses no longer need to invest in multiple machines or rely on time-consuming processes. A single Le-Leaser system can perform multiple functions, reducing labor requirements and accelerating production timelines. This integration also contributes to sustainability, as it lowers energy consumption and material waste, aligning with the growing global demand for eco-friendly manufacturing practices.

Beyond performance, Le-Leaser emphasizes user-friendly operation. The systems come equipped with intuitive interfaces, real-time monitoring, and safety protocols, making them accessible to both experienced engineers and operators new to laser technology. This ensures smooth adoption, minimal downtime, and optimal output from the very first day of implementation.

In addition, Le-Leaser continues to invest in research and development, exploring ways to expand the capabilities of laser integrated processing. Innovations such as adaptive laser control, multi-axis processing, and AI-assisted quality monitoring are set to redefine industry standards, giving manufacturers a competitive edge.

In conclusion, Le-Leaser’s laser integrated processing solutions are more than just tools—they represent a paradigm shift in modern manufacturing. By combining precision, efficiency, and sustainability, Le-Leaser empowers businesses to meet high-quality standards while optimizing operations. For companies looking to stay ahead of the curve, adopting laser integrated processing through Le-Leaser isn’t just an option; it’s a strategic move toward the future of manufacturing.