Why Should You Consider an ANSI Ball Valve Manufacturer for Your Projects?

An ANSI Ball Valve Manufacturer specializes in producing ball valves that comply with ANSI (American National Standards Institute) specifications, ensuring compatibility with various industrial piping systems. Ball valves are widely used for controlling the flow of liquids, gases, or steam, and their reliability directly affects operational efficiency. By working with an ANSI Ball Valve Manufacturer, industries can access products designed to meet precise standards and offer consistent performance across multiple applications.

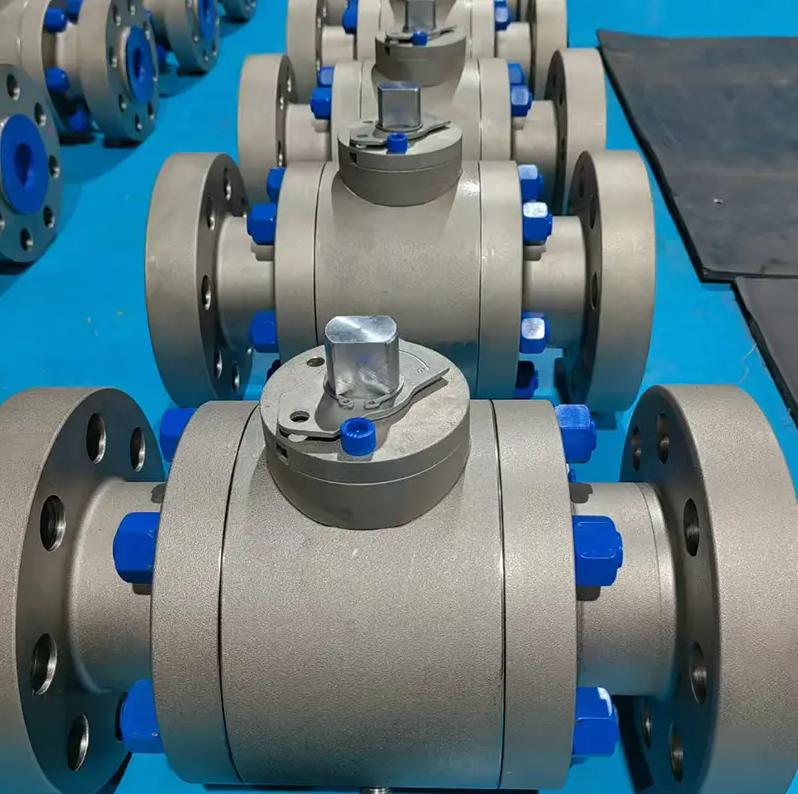

One of the key advantages of an ANSI Ball Valve Manufacturer is adherence to strict quality control measures. From selecting materials such as stainless steel, brass, or carbon steel to precision machining and assembly, each step is monitored to maintain functionality and durability. A well-managed ANSI Ball Valve Manufacturer ensures that each valve passes pressure tests, leak checks, and dimensional inspections before being delivered to clients. This approach minimizes operational disruptions and contributes to the overall safety of industrial systems.

Customization is another feature offered by an ANSI Ball Valve Manufacturer. Different applications may require valves with specific pressure ratings, sizes, end connections, or seat materials. By providing tailored solutions, an ANSI Ball Valve Manufacturer allows clients to select valves that suit unique operational requirements. This flexibility is particularly useful for industries such as oil and gas, chemical processing, water treatment, and manufacturing, where precise control of flow and pressure is critical.

Efficiency in production is also a consideration for an ANSI Ball Valve Manufacturer. Combining automated machining equipment with skilled technicians, manufacturers can produce high volumes of valves while maintaining consistent quality. Timely production ensures that clients receive valves according to project schedules, reducing downtime and supporting continuous operations. Reliable delivery from an ANSI Ball Valve Manufacturer contributes to smoother supply chain management for industrial clients.

Durability and performance are essential characteristics of valves produced by an ANSI Ball Valve Manufacturer. Valves must withstand high pressures, temperature fluctuations, and frequent operation without compromising sealing or structural integrity. Careful design, material selection, and precision assembly help ensure that ANSI ball valves provide reliable service over long periods, reducing maintenance needs and replacement frequency.

Applications of valves from an ANSI Ball Valve Manufacturer are diverse. They are commonly used in pipelines for controlling water, steam, oil, or gas flow, and are suitable for both on-off and throttling operations. Industries depend on ANSI Ball Valve Manufacturers to supply valves that maintain consistent performance under demanding conditions, supporting operational safety and process control.

Maintenance and support are additional considerations. Many ANSI Ball Valve Manufacturers provide technical documentation, spare parts, and guidance on installation or operation. This support helps clients maintain valves efficiently and extend their service life. By choosing a trusted ANSI Ball Valve Manufacturer, industries can ensure reliable access to quality valves for ongoing operations.

In conclusion, an ANSI Ball Valve Manufacturer provides essential components that support industrial systems by offering reliable, durable, and customizable valves. Through quality control, efficient production, and technical support, these manufacturers help industries maintain operational stability and process efficiency. Partnering with a reputable ANSI Ball Valve Manufacturer ensures access to valves that meet ANSI standards and deliver consistent performance in diverse applications.