Ultra-thin Glass Market – A New Era of Innovation and Flexibility

The Ultra-thin Glass Market is experiencing a revolution, driven by rising demand for lightweight, durable, and adaptable materials that redefine product engineering across industries. Once confined to niche electronic applications, ultra-thin glass now serves as a cornerstone of innovation in flexible devices, energy-efficient architecture, and advanced automotive systems. This blog examines the factors fueling its expansion, major industry trends, challenges, and the opportunities that lie ahead.

Market Overview

Ultra-thin glass, typically measuring below 1 mm in thickness, combines exceptional transparency, flexibility, and resilience. It serves as a bridge between traditional rigid glass and flexible polymers, offering superior scratch resistance and chemical stability. Its adoption has surged due to the global drive toward sleek, lightweight, and high-performance devices. As industries pursue efficiency and miniaturization, ultra-thin glass has become a fundamental material in achieving both functional and aesthetic excellence.

Key Growth Drivers

-

Technological Advancements in Displays

Foldable smartphones, flexible TVs, and curved monitors have become emblematic of modern innovation. Ultra-thin glass enables these designs by offering bendability without compromising durability. As consumer expectations rise for slimmer, stronger screens, manufacturers rely heavily on ultra-thin glass solutions. -

Shift Toward Sustainable Materials

Sustainability has emerged as a major driver. Ultra-thin glass is recyclable, eco-friendly, and energy-efficient in production compared to alternative substrates. Its integration into energy-saving architectural glass and solar panels contributes to global carbon reduction goals. -

Automotive Modernization

Automotive manufacturers are adopting ultra-thin glass for digital dashboards, heads-up displays, and sensor protection. As electric vehicles and autonomous systems proliferate, demand for high-performance, lightweight glass components continues to rise. -

Innovations in Production Processes

Recent breakthroughs in fusion-draw and chemical-tempering techniques allow for mass production of thinner glass sheets with enhanced flexibility. This progress has significantly reduced manufacturing defects, enabling scalable deployment across industries.

Challenges Facing the Market

Despite its growth trajectory, the ultra-thin glass market faces notable obstacles. Production complexity and high initial investment costs remain barriers for small-scale manufacturers. Handling fragility during fabrication also increases operational risk. Moreover, price-sensitive industries often opt for cheaper alternatives like polymer films. However, long-term benefits—such as longevity, clarity, and environmental sustainability—make ultra-thin glass a superior choice in high-value applications.

Regional Landscape

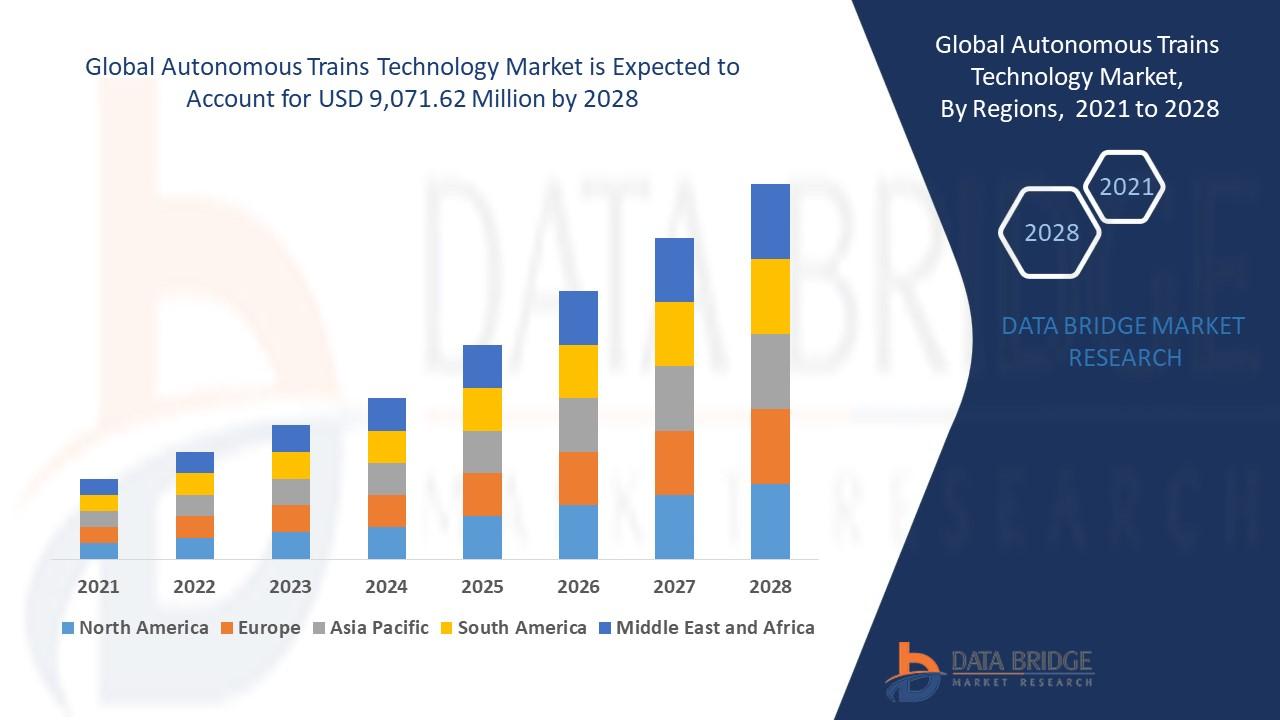

The market’s regional dynamics reveal strong dominance by Asia-Pacific, home to global display and semiconductor giants. China, Japan, and South Korea lead in both production and consumption. Europe and North America follow closely, driven by the adoption of advanced automotive and energy solutions. Emerging economies are gradually entering the landscape as foreign investments in manufacturing infrastructure expand.

Industry Trends

The ultra-thin glass market is evolving rapidly, marked by trends such as:

-

Increased collaboration between material suppliers and electronics manufacturers.

-

Growing R&D focus on flexible and foldable variants.

-

Integration of smart functionalities in architectural applications.

-

Accelerated shift toward carbon-neutral manufacturing.

These developments indicate a future defined by both performance optimization and environmental responsibility.

Future Prospects

The future outlook for the ultra-thin glass market is exceptionally bright. As smart technologies continue to converge with material innovation, demand will expand across consumer electronics, automotive, and renewable sectors. Ongoing efforts to enhance mechanical flexibility and cost efficiency are expected to unlock new commercial possibilities. By 2030 and beyond, ultra-thin glass is poised to become an essential material standard in sustainable industrial design.

Conclusion

In essence, the Ultra-thin Glass Market stands at the forefront of a new material revolution. Its unmatched blend of functionality, flexibility, and sustainability ensures its growing role in reshaping product innovation worldwide. With continuous technological advancements and widening applications, ultra-thin glass is set to remain a defining component of the next generation of global manufacturing and design.