Innovations in Stretch and Shrink Films

Plastic films have become vital components in various sectors, including packaging, agriculture, construction, and healthcare. The versatility, durability, and plastic film manufacturer lightweight nature of plastic films make them indispensable in meeting the demands of today’s fast-paced market. As businesses increasingly rely on these materials, plastic film manufacturers play a crucial role in providing high-quality solutions tailored to specific industry needs.

Understanding Plastic Films

Plastic films are thin sheets made from various types of polymers, such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). These films can be produced using processes like extrusion, casting, and blowing, resulting in a range of thicknesses, textures, and finishes. Depending on the application, plastic films can be transparent, opaque, or colored, offering flexibility for numerous uses.

Key Applications

-

Packaging: One of the primary applications of plastic films is in packaging. They are widely used to wrap food products, pharmaceuticals, and consumer goods, providing essential protection against moisture, dust, and contaminants. Their lightweight nature reduces shipping costs, making them an economical choice for manufacturers.

-

Agriculture: In the agricultural sector, plastic films are employed for greenhouse coverings, mulch films, and silage. These applications help create controlled environments that enhance crop growth, improve yields, and protect against pests and weather conditions. Agricultural films are often designed with UV protection to prevent degradation from sunlight.

-

Construction: Plastic films play a critical role in the construction industry, serving as vapor barriers, insulation materials, and protective coverings. They help manage moisture, enhance energy efficiency, and protect building materials during construction.

-

Healthcare: In healthcare settings, plastic films are used for sterile packaging, disposable medical supplies, and protective barriers. Their ability to provide a hygienic and safe environment is crucial in maintaining health standards.

The Manufacturing Process

The production of plastic films involves several stages, starting with the selection of raw materials. Manufacturers must ensure that the polymers used meet specific quality and safety standards. The most common production method is extrusion, where plastic pellets are melted and formed into thin sheets. These sheets may undergo additional processes like stretching or laminating to enhance their properties.

Quality control is paramount throughout the production process. Manufacturers conduct rigorous testing to ensure that the films meet industry specifications and are free from defects. This attention to detail ensures that businesses receive reliable and high-quality products.

Selecting a Plastic Film Manufacturer

When choosing a plastic film manufacturer, several factors should be considered:

-

Quality Assurance: Look for manufacturers that adhere to industry standards and have a reputation for producing high-quality films. Certifications and testing protocols can provide confidence in the product's reliability.

-

Customization: The ability to customize film specifications, such as thickness, color, and print capabilities, is crucial for businesses seeking to differentiate their products.

-

Sustainability Practices: With increasing environmental concerns, manufacturers that prioritize sustainable practices, such as using recyclable materials or biodegradable options, can enhance a brand’s reputation.

-

Customer Service: A responsive and knowledgeable customer service team is essential for addressing issues and facilitating smooth communication throughout the production process.

Industry Trends

The plastic film industry is evolving, influenced by consumer preferences and technological advancements. Key trends include a shift towards sustainable materials, the incorporation of smart packaging technologies, and the development of lighter, stronger films that reduce waste.

Conclusion

Plastic film manufacturers are integral to many industries, providing essential materials that enhance functionality and efficiency. By understanding the applications, manufacturing processes, and current trends, businesses can make informed decisions when selecting plastic film solutions. As the demand for innovative and sustainable packaging continues to grow, manufacturers who adapt to these changes will be well-positioned for future success.

Categorias

Leia mais

Cobra Kai Final Season Highlights Exciting updates from the Miyagiverse: the concluding five episodes of Cobra Kai Season 6 are now available to stream. The final season's second part takes viewers to Spain, where Miyagi-Do competes in the prestigious Sekai Taikai tournament. As they face formidable opponents and confront past rivalries, the team strives for ultimate glory. However, the...

The start of a new year always brings momentum, but 2026 feels different in a meaningful way. Over the past several months, much of our focus has been on building, refining, and preparing systems that are only now beginning to surface. While many of these efforts have been happening behind the scenes, the impact of that work is about to become far more visible. This first blog post of the year...

Choosing the right career path in the tech world can be exciting yet confusing—especially when it comes to budgeting for skill development. Software testing has become one of the fastest-growing roles in the IT sector because every company needs quality assurance experts to ensure their applications run smoothly. If you're planning to pursue a Software testing course in Kerala, one...

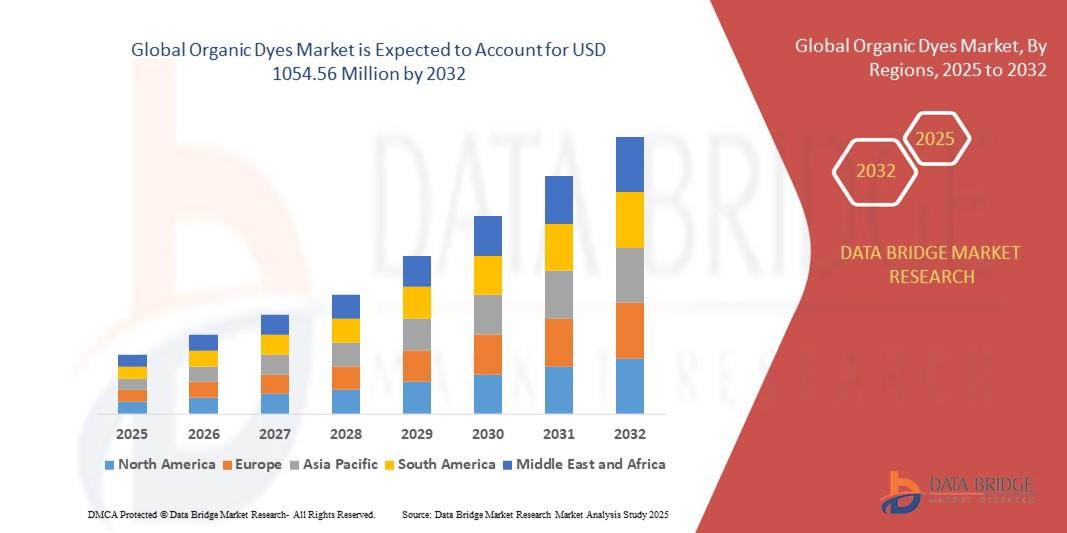

"Key Drivers Impacting Executive Summary Organic Dyes Market Size and Share CAGR Value The global organic dyes market size was valued at USD 681.96 million in 2024 and is expected to reach USD 1054.56 million by 2032, at a CAGR of 5.60% during the forecast period The credible Organic Dyes Marketreport comprises of various segments linked to Organic Dyes Market industry...

Market Trends Shaping Executive Summary Baby Monitors Market Size and Share Data Bridge Market Research analyses that the baby monitors market which was USD 1.395 billion in 2021, is expected to reach USD 2.14 billion by 2029, at a CAGR of 5.5% during the forecast period 2022 to 2029. Baby Monitors report has been formulated by keeping in mind all the vital aspects of the...