Inventory Management Outsourcing for Seasonal and Peak Demand Control

Seasonal demand can make inventory management feel like a balancing act. One moment your warehouse is full, and the next, stock is flying out faster than you can replenish it. Retailers, eCommerce brands, manufacturers, and distributors all face the same challenge: how to maintain the right inventory levels when demand isn’t steady year-round.

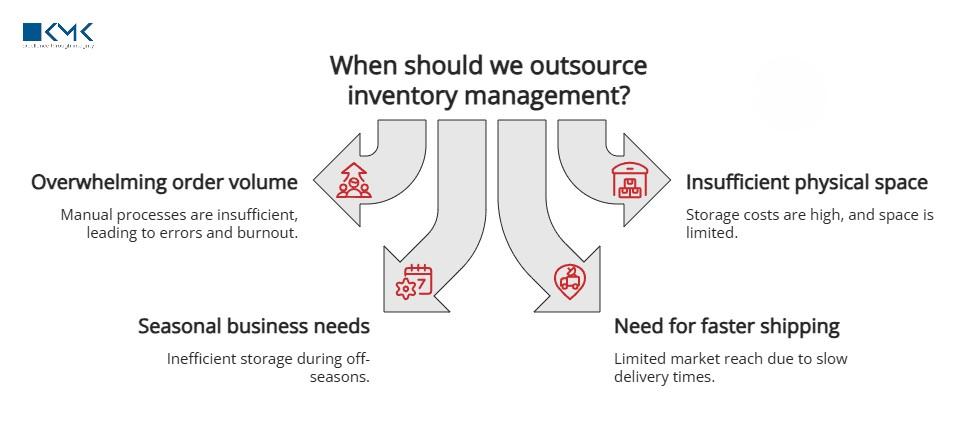

This is where partnering with an inventory management outsourcing company becomes a strategic advantage. Outsourcing helps businesses stay prepared for peak seasons, sudden demand surges, or unexpected slowdowns — without increasing operational overhead or overburdening internal teams.

In this article, we’ll explore why seasonal inventory volatility happens, how outsourcing helps control it, and why more US businesses are shifting to external inventory specialists to maintain efficiency and profitability throughout the year.

Why Seasonal and Peak Demand Volatility Matters

Seasonality is more common than many realize. Clothing brands face fashion cycles. Restaurants and beverage suppliers see festive spikes. Electronics businesses feel holiday rushes. Even B2B manufacturers experience contract-based or market-driven fluctuations.

The real problem is inventory imbalance:

-

Overstocking ties up cash in unsold inventory.

-

Understocking leads to lost sales and disappointed customers.

When demand shifts suddenly, businesses without a well-structured inventory control strategy risk:

-

Production delays

-

Increased storage costs

-

Emergency restocking expenses

-

Damaged customer relationships

If your inventory process only works “when things are normal,” it’s not ready for real-world business cycles.

The Challenge: Why In-House Teams Struggle During Peak Seasons

Managing inventory internally can work well during stable periods. But during peak seasons, everything accelerates — and internal teams may not have the resources, forecasting tools, or bandwidth needed.

Common challenges include:

| Challenge | Impact During Demand Peaks |

|---|---|

| Manual inventory tracking | Delays, errors, and stock mismatches |

| Limited forecasting data | Inaccurate demand planning |

| Space limitations | Overstock or overflow storage costs |

| Slow restocking workflows | Backorders and customer dissatisfaction |

| Understaffed warehouse teams | Operational bottlenecks |

In other words, demand moves faster than internal processes can handle.

Outsourcing helps bridge this performance gap.

How Outsourcing Supports Seasonal and Peak Demand Control

An experienced outsourcing partner brings technology, workforce scalability, and process efficiency — all crucial for managing seasonality.

1. Accurate Demand Forecasting

Outsourced teams use advanced analytics, historical sales data, and market trends to predict demand spikes before they occur. This ensures businesses purchase, store, and supply inventory at optimal levels without guesswork.

2. Scalable Workforce and Storage

Instead of hiring temporary staff or leasing more warehouse space, outsourcing provides dynamic scaling. When demand rises, resources increase. When demand drops, operations scale back — without extra overhead.

3. Real-Time Inventory Visibility

Outsourcing providers often use cloud-based systems that integrate with ERP, WMS, and eCommerce platforms. This enables:

-

Real-time inventory count

-

Multi-location stock tracking

-

SKU-level performance monitoring

Better visibility means smarter decisions.

4. Faster Order Fulfillment

During peak periods, fulfillment speed determines customer satisfaction. Outsourced inventory teams ensure:

-

Faster pick, pack, and ship cycles

-

Efficient warehouse workflows

-

Reduced delays and backorders

This leads to repeat sales and stronger brand trust.

5. Reduced Storage and Handling Costs

Inventory outsourcing eliminates the need for businesses to expand physical warehouses or hire seasonal staff. Providers handle storage, labor, packaging, and logistics — often at a lower cost due to economies of scale.

The Real Financial Impact: More Than Just Cost Savings

Many companies initially outsource to reduce expenses — but the benefits go far beyond cost control.

Faster Cash Flow

With accurate stock levels and fewer unsold goods, companies maintain healthy working capital.

Reduced Risk of Stockouts

Better forecasting and faster replenishment prevent lost sales during high-demand periods.

Improved Customer Experience

When customers receive orders on time, trust in the brand increases — leading to loyalty and referrals.

Operational Stability

Even during sudden demand surges, the business remains efficient and predictable.

A Quick Example: Seasonal Retail Brand Case Study

A US-based apparel retailer faced massive demand spikes every summer and winter. Their internal team struggled with forecasting and fulfillment, causing frequent stockouts and excessive clearance sales.

After partnering with an inventory management outsourcing provider:

-

Forecast accuracy improved by 37%

-

Overstock reduced by 28%

-

Delivery time dropped from 5 days to 48 hours

-

Seasonal profitability increased by 22%

The retailer didn’t change products — they changed how they managed inventory.

Choosing the Right Outsourcing Partner: What to Look For

Not all outsourcing firms offer the same capabilities. When selecting a provider, evaluate:

| Criteria | What It Means |

|---|---|

| Industry Experience | Familiarity with your product cycles and demand patterns |

| Tech Integration | Ability to sync with your ERP, accounting, and sales platforms |

| Scalability | Can expand or reduce operations with seasonal needs |

| Storage & Logistics Capability | Access to multi-location warehouses and distribution hubs |

| Reporting and Transparency | Real-time dashboards, weekly reporting, and performance metrics |

A strategic outsourcing relationship should feel like an extension of your team — not just a vendor arrangement.

Final Thoughts

Managing inventory during seasonal and peak demand periods is one of the most challenging aspects of business operations. But with the right partner, it becomes a controlled, predictable, and data-driven process.

Outsourcing allows businesses to:

-

Maintain optimal stock levels

-

Reduce costs

-

Improve fulfillment speed

-

Protect profitability

-

Stay ready for demand — anytime, anywhere

In a competitive market where customer expectations are rising, inventory stability is not just operational — it’s strategic.