Industrial Coatings Market to Reach USD 161.06 Billion by 2032

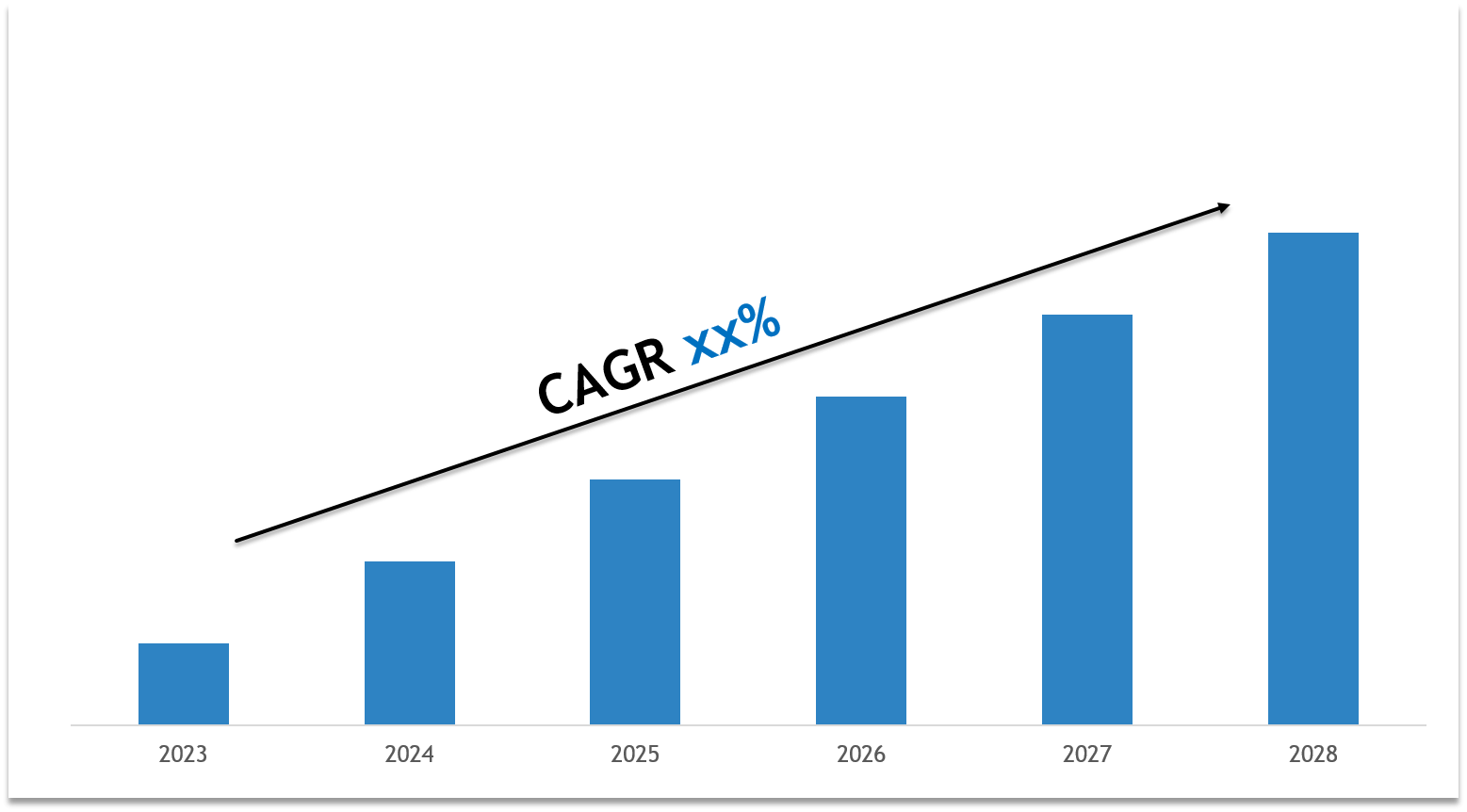

The Global Industrial Coatings Market, valued at USD 116.38 billion in 2023, is projected to reach USD 161.06 billion by 2032, growing at a compound annual growth rate (CAGR) of 3.68% during the forecast period 2024–2032. The market is expanding due to increasing demand from automotive, aerospace, marine, and industrial sectors, along with rising adoption of environmentally friendly coatings, advanced polymer formulations, and high-performance protective solutions.

Industrial coatings are specialized protective or decorative finishes applied to various substrates to enhance durability, corrosion resistance, chemical resistance, and aesthetic appeal. These coatings are widely used across metal, concrete, plastics, and composite surfaces in sectors such as construction, energy, transportation, and manufacturing, where protection against environmental and mechanical wear is critical.

Get Free Sample Report@ https://www.snsinsider.com/sample-request/1709

Market Overview

The global industrial coatings market is witnessing steady growth, driven by the need for improved durability, corrosion resistance, and operational efficiency in industrial and infrastructure applications. With rising industrialization, urbanization, and infrastructure development worldwide, demand for coatings that extend asset life, reduce maintenance costs, and enhance product aesthetics is increasing.

Technological advancements in coating formulations, including waterborne, solvent-borne, powder coatings, and hybrid systems, are further boosting adoption. Regulatory pressures to minimize volatile organic compounds (VOCs) and environmentally harmful solvents are driving growth in eco-friendly, low-emission coatings, particularly in North America and Europe.

Additionally, increasing investments in oil & gas, power generation, and mining sectors require high-performance protective coatings capable of withstanding harsh chemical and environmental conditions. Automotive, aerospace, and electronics sectors are also major contributors, adopting industrial coatings to meet durability, aesthetic, and performance standards.

Key Market Segments

By Product

- Acrylic Coatings

Acrylic coatings dominate the market due to their weather resistance, durability, and versatility. They are extensively used in automotive refinishing, general industrial applications, and architectural coatings. - Alkyd Coatings

Alkyd coatings are valued for their cost-effectiveness, adhesion, and flexibility, commonly applied in metal, wood, and industrial machinery for protective purposes. - Polyurethane (PU) Coatings

PU coatings offer high chemical, abrasion, and UV resistance, making them ideal for automotive, aerospace, and industrial machinery applications. - Epoxy Coatings

Epoxy coatings are widely used for corrosion protection, chemical resistance, and high-strength bonding in sectors such as oil & gas, marine, and infrastructure. - Polyester Coatings

Polyester coatings are preferred for their durability, chemical resistance, and aesthetic appeal, often used in powder coatings for appliances, automotive parts, and industrial equipment. - Others

This segment includes fluoropolymer, silicone, and specialty hybrid coatings, which are increasingly adopted in high-performance and niche industrial applications.

By Technology

- Solvent-Borne Coatings

Solvent-borne coatings continue to dominate certain industrial sectors due to strong adhesion, chemical resistance, and ease of application, despite rising environmental regulations. - Water-Borne Coatings

Water-borne coatings are growing rapidly, driven by low VOC content, environmental compliance, and improved performance. They are widely used in automotive, electronics, and general industrial applications. - Powder-Based Coatings

Powder coatings provide high durability, corrosion resistance, and aesthetic quality while being environmentally friendly. Adoption is increasing in appliances, automotive, and industrial equipment. - Others

This includes UV-curable, hybrid, and fluoropolymer coatings, often applied in specialized industrial and high-performance applications.

By End-Use Industry

- General Industrial

Industrial coatings are applied on machinery, tools, and metal components, improving durability, performance, and aesthetics across manufacturing facilities. - Marine

Marine coatings are used to protect ships, offshore platforms, and marine equipment against corrosion, fouling, and harsh environmental conditions. - Automotive & Vehicle Refinish

The automotive sector drives significant demand for industrial coatings for bodywork, interior components, and refinishing, emphasizing durability, appearance, and chemical resistance. - Electronics

Electronics coatings protect circuit boards, devices, and components from moisture, corrosion, and thermal stress, ensuring long-term reliability. - Aerospace

Aerospace coatings are applied to aircraft structures, interiors, and components, offering high-performance protection against extreme temperatures, corrosion, and wear. - Oil & Gas

Industrial coatings are critical for pipelines, storage tanks, and equipment in oil & gas operations, providing resistance to chemicals, corrosion, and mechanical stress. - Mining

Coatings are used on mining machinery, conveyors, and equipment, enhancing durability and minimizing wear in abrasive and corrosive environments. - Power Generation

Industrial coatings protect turbines, boilers, and transmission equipment against high temperatures, chemical exposure, and environmental degradation. - Others

Other industries, including construction, packaging, and consumer goods manufacturing, are adopting industrial coatings to enhance performance, longevity, and product appeal.

Regional Insights

Asia-Pacific dominates the industrial coatings market due to rapid industrialization, infrastructure development, and automotive expansion in countries like China, India, Japan, and South Korea. The growing construction, manufacturing, and energy sectors are significant contributors.

North America maintains a substantial share, supported by advanced manufacturing, automotive production, and stringent environmental regulations driving the adoption of eco-friendly coatings.

Europe is witnessing steady growth due to government regulations, adoption of low-VOC coatings, and demand from automotive, aerospace, and industrial machinery sectors.

Emerging markets in Latin America and Middle East & Africa are gradually adopting industrial coatings, driven by industrial expansion, energy infrastructure projects, and mining operations.

Competitive Landscape

The global industrial coatings market is moderately consolidated with major players focusing on product innovation, sustainability, and geographic expansion. Key players include PPG Industries, Sherwin-Williams, AkzoNobel, Axalta Coating Systems, BASF SE, Jotun, RPM International, and Kansai Paint Co., Ltd.

Market participants are investing in waterborne and powder coatings, hybrid technologies, and high-performance formulations to meet environmental regulations and evolving industrial requirements. Strategic partnerships with industrial manufacturers, automotive OEMs, and energy companies are enhancing market reach and product adoption globally.

Future Outlook

The future of the industrial coatings market is promising, driven by industrialization, technological advancements, and environmental sustainability initiatives. With applications across automotive, aerospace, marine, electronics, oil & gas, and power generation, demand for high-performance, low-VOC, and durable coatings is expected to grow steadily.

By 2032, as the market reaches USD 161.06 billion, industrial coatings will play a pivotal role in protecting assets, improving performance, and supporting sustainable industrial growth, while enabling manufacturers to meet the growing need for durable, efficient, and environmentally compliant solutions.

Related Reports

About Us:

S&S Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Rohan Jadhav – Principal Consultant

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Email: info@snsinsider.com