Battery Coating Market Analysis, Insights and Future Opportunities

The global Battery Coating Market, valued at USD 325 million in 2023, is projected to reach USD 1,130 million by 2032, growing at a CAGR of 14.8% during the forecast period 2024–2032. Rapid advancements in electric mobility, energy storage systems, and portable electronics are fueling strong demand for high-performance coatings that enhance battery efficiency, safety, and lifespan.

Battery coatings are specialized materials applied to various battery components—including electrodes, separators, and packs—to improve conductivity, thermal stability, and resistance to corrosion or degradation. As manufacturers seek to optimize energy density and extend the operational life of next-generation batteries, the role of coating technologies has become increasingly critical across the global energy landscape.

Get Free Sample Report@ https://www.snsinsider.com/sample-request/2456

Market Overview

The accelerating adoption of electric vehicles (EVs) and renewable energy storage systems is transforming the battery manufacturing sector. Coating technologies are essential in maintaining stability, preventing unwanted reactions, and improving charge-discharge efficiency in modern batteries.

Innovations in surface engineering, nanotechnology, and deposition techniques have led to the development of advanced coatings that enhance performance even under extreme temperature and high-voltage conditions. As a result, industries are investing heavily in coating technologies to meet growing energy demands while adhering to environmental and safety standards.

Moreover, government incentives promoting EV adoption, along with global sustainability goals, are encouraging battery manufacturers to integrate durable and cost-effective coating solutions into their production processes.

Market Segmentation Highlights

By Type

- Atomic Layer Deposition (ALD):

ALD coatings are witnessing high adoption due to their ability to create ultra-thin, uniform layers that enhance electrode stability and prevent lithium dendrite formation. ALD technology plays a crucial role in improving cycle life and energy efficiency in lithium-ion batteries. - Physical Vapor Deposition (PVD):

PVD coatings provide excellent adhesion and thermal stability, making them suitable for battery electrodes exposed to high operating temperatures. This technology is gaining traction in EV and aerospace energy storage systems. - Plasma Enhanced Chemical Vapor Deposition (PECVD):

PECVD offers advantages such as precise film thickness control and compatibility with complex geometries, enabling enhanced performance and safety for high-energy-density batteries. - Chemical Vapor Deposition (CVD):

CVD coatings are used to improve conductivity and chemical resistance in electrodes and separators. Their scalability and uniformity make them ideal for mass battery production. - Dry Powder Coating:

This environmentally friendly process eliminates the need for solvents, reducing waste and emissions. It provides excellent mechanical strength and corrosion protection, particularly for battery pack coatings.

By Battery Component

- Electrode Coating:

The largest segment by share, electrode coatings improve energy efficiency, cycle stability, and conductivity. These coatings minimize electrode degradation and enhance charge retention, critical for lithium-ion and emerging battery chemistries. - Separator Coating:

Separator coatings enhance safety by preventing short circuits and improving thermal resistance. Ceramic and polymer coatings are widely used to improve separator performance and mechanical stability. - Battery Pack Coating:

Increasing adoption of EVs and energy storage systems is driving demand for protective coatings that safeguard battery packs from moisture, vibration, and temperature fluctuations.

By Battery Type

- Lithium-Ion Battery:

Dominates the market due to widespread use in EVs, consumer electronics, and renewable energy storage. Coatings enhance the performance, safety, and longevity of lithium-ion cells, making them central to the industry’s evolution. - Lead-Acid Battery:

While traditional, this segment remains significant in automotive and industrial applications. Coating technologies help reduce sulfation and extend battery service life. - Nickel-Cadmium Battery:

Used in industrial and backup power applications, coatings improve corrosion resistance and performance consistency. - Graphene Battery:

An emerging segment, graphene-based batteries benefit from advanced coatings that enhance conductivity and structural integrity, supporting innovation in fast-charging technologies.

By Material Type

- Polyvinylidene Fluoride (PVDF):

One of the most widely used coating materials due to its high chemical resistance, adhesion, and thermal stability, particularly for electrode and separator coatings. - Ceramic:

Ceramic coatings are known for improving heat resistance, safety, and structural integrity. They are increasingly used in high-performance EV batteries. - Alumina:

Provides excellent insulation and acts as a protective layer against corrosion and chemical degradation in electrodes and separators. - Oxide:

Oxide coatings such as titanium oxide and silicon oxide enhance cycle life and conductivity. These materials are gaining attention in next-generation lithium and solid-state batteries. - Carbon:

Carbon-based coatings improve electrical conductivity and are commonly used in cathode and anode layers to increase power output. - Polyurethane (PU) and Epoxy:

These coatings are used primarily in battery pack protection for their strong adhesion, flexibility, and resistance to mechanical stress and environmental factors. - Others:

Includes hybrid and nanocomposite materials that offer customized properties for specialized battery designs.

Regional Trends

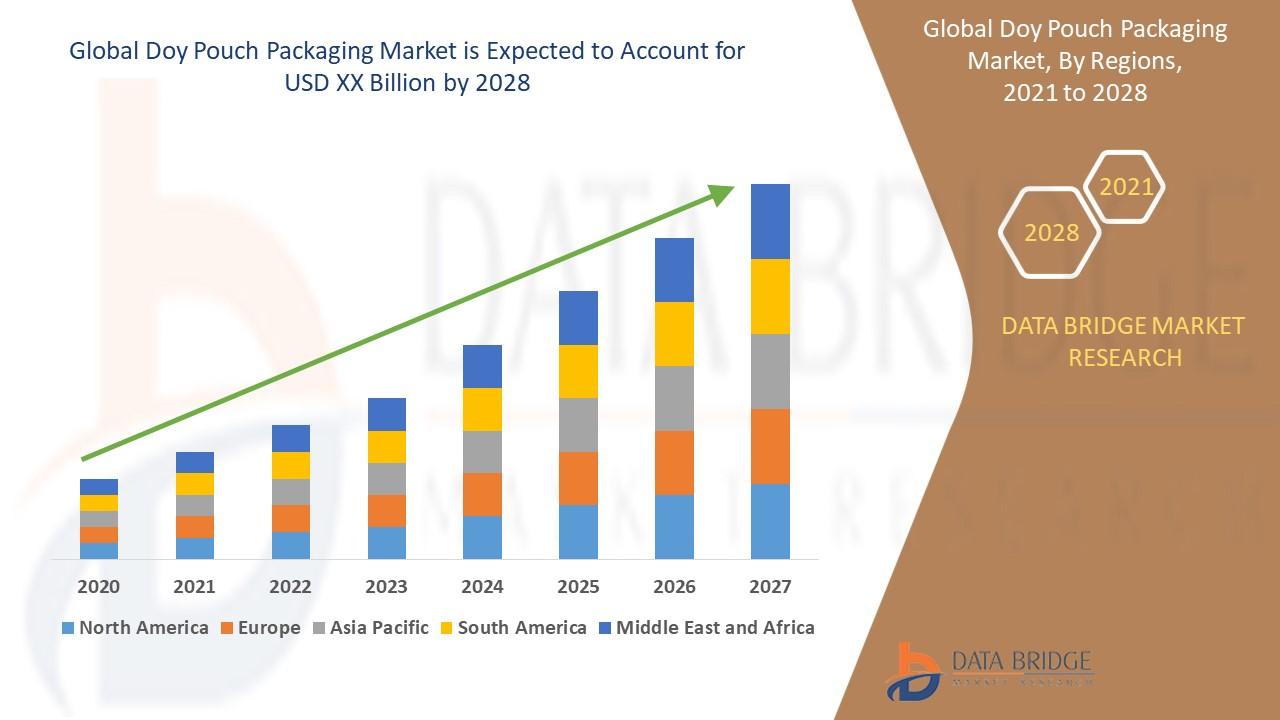

Asia-Pacific dominates the global battery coating market, accounting for the largest share in both production and consumption. Countries such as China, Japan, and South Korea are leading innovation in lithium-ion battery manufacturing, supported by robust EV industries and technological expertise.

Europe is witnessing rapid market expansion, driven by strict environmental policies, growing EV adoption, and government incentives promoting local battery production. Germany, France, and the Nordic countries are investing heavily in gigafactories and sustainable coating technologies.

North America shows strong growth, supported by investments from automotive OEMs and energy storage developers. The United States is focusing on developing advanced coating technologies for EV and grid storage applications to reduce dependency on imports.

Emerging markets in Latin America and the Middle East & Africa are also gaining momentum as infrastructure for renewable energy and electric mobility continues to develop.

Market Drivers and Emerging Trends

- Rising Adoption of Electric Vehicles (EVs):

EV expansion worldwide is the most significant driver, with battery coatings improving performance, range, and charging efficiency. - Advancements in Energy Storage Systems:

The growth of renewable energy and grid storage solutions is creating sustained demand for high-performance, durable battery coatings. - Innovation in Coating Materials and Deposition Technologies:

Development of nanostructured coatings and hybrid materials is enhancing conductivity, safety, and environmental sustainability. - Sustainability and Environmental Regulations:

Focus on solvent-free and recyclable coating methods is aligning with global sustainability goals and green manufacturing initiatives. - Growing Investment in R&D:

Battery manufacturers and research institutions are investing in next-generation coatings for solid-state, lithium-sulfur, and graphene-based batteries to meet future energy needs.

Future Outlook

The global battery coating market is expected to grow exponentially as demand for cleaner energy and electrified transportation continues to rise. Technological innovation, government support, and global sustainability initiatives are expected to fuel long-term growth.

Manufacturers are focusing on cost-effective coating solutions, recyclable materials, and automation in production to scale operations efficiently. Emerging opportunities in solid-state battery technology and fast-charging EV infrastructure will further redefine the competitive landscape through 2032.

Related Reports

About Us:

S&S Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Rohan Jadhav – Principal Consultant

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Email: info@snsinsider.com