Commercial Vehicle Wiring Harness Market Forecast: Trends, Drivers & Outlook

The Commercial Vehicle Wiring Harness Market is poised for strong growth as commercial vehicles evolve with electrification, advanced driver-assistance systems (ADAS), telematics, and high-voltage powertrains. Wiring harnesses are becoming the backbone of modern commercial vehicles, supporting both power delivery and data communication for increasingly complex systems.

Key Growth Drivers

One of the main drivers of market expansion is the shift toward electric and hybrid commercial vehicles. These vehicles rely on high-voltage wiring harnesses to connect batteries, control modules, and power electronics. As electrification increases, harnesses must handle higher currents safely and efficiently while ensuring reliability.

Another driver is the integration of electronics and telematics. Commercial vehicles are adopting real-time diagnostics, fleet management systems, and connectivity features, which require wiring harnesses capable of transmitting both power and high-speed data.

Material innovation is also important. While copper remains dominant due to its conductivity and reliability, aluminum is increasingly used for its lightweight properties and cost benefits. Modular harness designs are emerging, allowing easier installation and maintenance by segmenting harnesses into preconfigured modules for engines, cabins, and sensor systems.

Market Trends & Dynamics

-

Electrification & High-Voltage Harnesses

Electrified vehicles require harnesses that can manage high voltage and current. Advanced insulation, durable connectors, and optimized routing are essential to ensure safety and efficiency. -

Data-Rich Harnesses

Modern commercial vehicles carry a large volume of data for ADAS, telematics, and safety systems. Harnesses are evolving to support high-speed data transfer, often incorporating shielded cables and twisted-pair wiring. -

Lightweight Materials

The industry is increasingly adopting aluminum and hybrid materials to reduce vehicle weight and improve efficiency. -

Regional Growth

Emerging markets are seeing rapid expansion in commercial vehicle production, creating strong demand for wiring harnesses. Mature markets continue to push for advanced systems that meet regulatory and safety requirements.

Challenges & Risks

-

Complexity & Cost: Advanced harnesses are more complex to design and manufacture, increasing production costs.

-

Material Price Volatility: Fluctuating prices of copper and other metals can affect overall costs.

-

Regulatory Differences: Diverse standards across regions make global standardization difficult.

-

Talent Shortage: Skilled engineers are needed for high-voltage, data-rich, and modular harness designs, creating workforce challenges.

Market Forecast & Outlook

The commercial vehicle wiring harness market is expected to grow significantly over the next decade. Demand will be driven by the rise of electric and hybrid vehicles and the increasing electronic content of commercial fleets. Segment-wise, lighting and power distribution harnesses remain significant, while safety system harnesses for ADAS applications are gaining traction. Copper continues to dominate in terms of material usage, but aluminum is growing faster due to its weight-saving benefits.

Heavy-duty trucks, buses, and specialty utility vehicles will continue to require reliable and scalable wiring solutions. Manufacturers are focusing on modular designs, prewired subsystems, and simulation-based design tools to optimize cost and performance.

FAQs

1. Why are wiring harnesses important in electric commercial vehicles?

Electric vehicles require high-voltage systems, and wiring harnesses must safely handle power delivery, high current, and insulation, while also integrating control and data lines.

2. What materials are used in commercial vehicle wiring harnesses?

Copper is widely used for conductivity and durability, while aluminum is increasingly preferred for its lighter weight and cost advantages.

3. What are the main challenges for wiring harness manufacturers?

Manufacturers face complex designs, high costs, regulatory differences across regions, and a shortage of skilled engineers for advanced harness systems.

The Commercial Vehicle Wiring Harness Market is set to grow rapidly, driven by electrification, connectivity, and modular design. Wiring harnesses are no longer just a component; they are a critical part of modern commercial vehicles, enabling power distribution, communication, and safety systems while shaping the future of fleet technology.

More Related Report

Commercial Vehicle Telematics Market Size

Electric Cargo Bikes Market Size

Categorias

Leia mais

The online betting industry in the UK has seen remarkable growth over the years, becoming a major part of the country's entertainment landscape. With a variety of betting sites available, punters have a wealth of options at their fingertips. This article will explore the different aspects of betting sites in the UK, uk betting sites including types of bets, popular sports, legal...

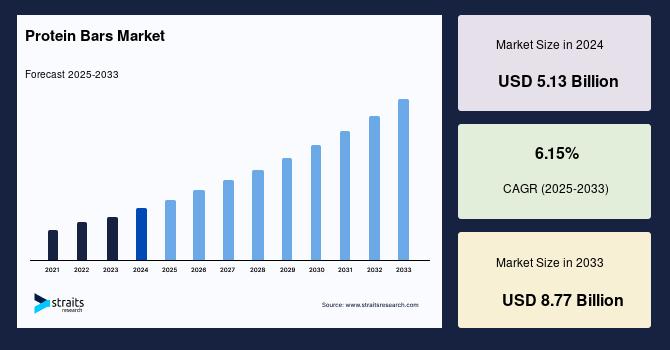

The Global Protein Bars Market Report 2025 offers a thorough and data-driven analysis of the Protein Bars Market industry, covering key aspects such as market size, growth drivers, limitations, and future prospects. Market analysts meticulously collect data using polls, focus groups, and thorough examination of industry trends. Through a combination of quantitative and qualitative...

Facing regulatory pressures under the UK's Online Safety Act, Twitch enforces biometric verification for viewers accessing mature streams. The mandate targets content involving sexual themes, substance intoxication, and gambling. Existing users encounter prompts for facial scans during login or when attempting restricted content. Partnering with k-id, Twitch conducts on-device age estimation...

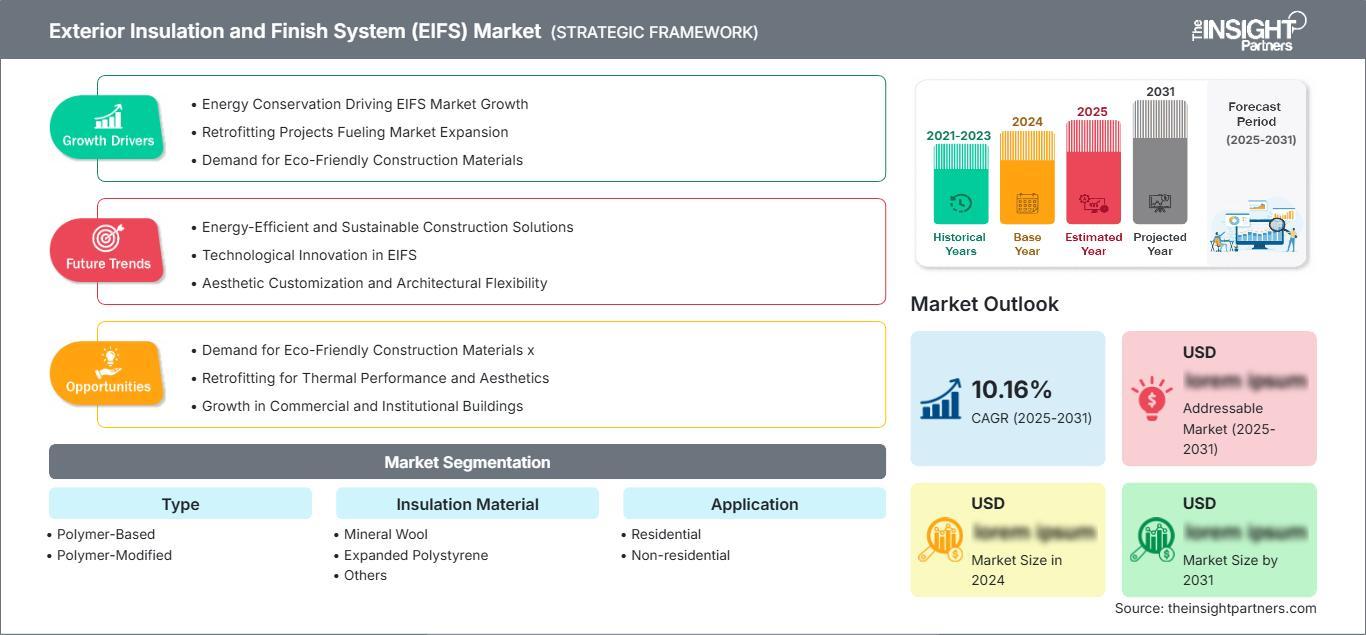

United States of America– 02 Dec 2026- The Exterior Insulation and Finish System (EIFS) market continues to gain momentum as builders prioritize energy-efficient and aesthetically versatile solutions for modern construction. Driven by global demands for sustainable building practices, EIFS offers superior thermal performance and design flexibility across residential and...

In a highly competitive market, packaging plays a decisive role in shaping customer perception. For pre roll products, where presentation, protection, and compliance are equally important, luxury pre roll boxes offer a sophisticated packaging solution that elevates brand value. Designed with premium materials and refined finishes, luxury pre roll boxes not only protect the product but also...