From Metal Blank to Flip Key: The Production Steps of Switchblade Key Blades

The production of a switchblade key blade, also known as a flip key blade, involves a series of precise and carefully controlled steps to ensure durability, accuracy, and compatibility with modern vehicle lock systems. These blades must meet strict mechanical and security standards, making the manufacturing process both technical and detail-oriented.

The first step in producing a switchblade key blade is material selection. High quality metals such as stainless steel or brass alloys are chosen for their strength, corrosion resistance, and ability to withstand repeated folding and insertion into lock cylinders. Once the material is selected, it is cut into rough key shaped blanks using stamping or CNC cutting machines.

The second step is precision machining. The blade undergoes milling or laser cutting to create the specific groove patterns required for a vehicle’s lock system. These patterns must be exact to ensure proper alignment and security. Advanced lasercut or sidewinder designs require high accuracy machining to achieve the complex internal and external cuts.

Following machining, the blade is polished and surface treated. This step removes burrs, enhances smoothness, and increases corrosion resistance. Some manufacturers apply additional coatings for improved durability or aesthetic appeal.

The fourth step is assembly. The finished blade is mounted into the switchblade key housing, which includes a spring loaded mechanism that enables the blade to flip open and retract smoothly. Technicians align the blade with the internal pivot pin, secure it in place, and test the flipping mechanism for proper tension and functionality.

Finally, quality inspection is performed. Each switchblade key blade is checked to ensure accurate cutting, smooth operation, and compatibility with the intended vehicle model.

https://www.hc-key.com/product/foldable-key-blank/

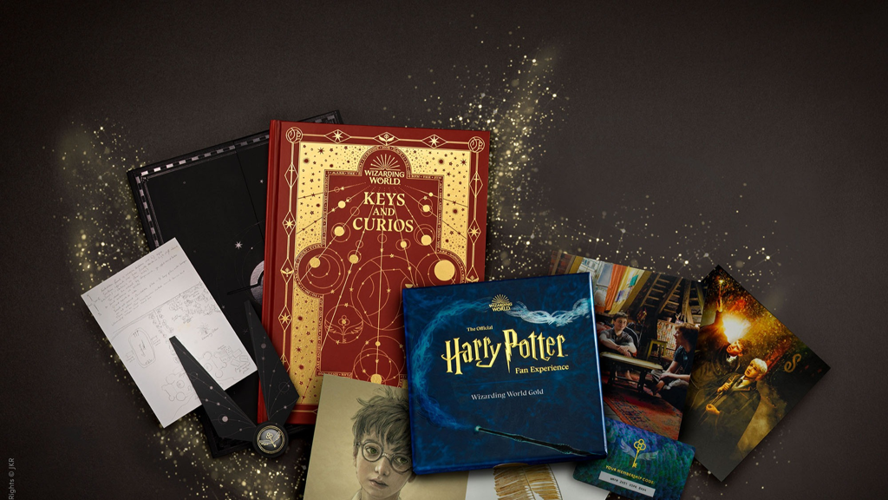

Foldable Key Blade For Brilliance Gold Cup Isuzu Haima

Applicable models: Brilliance Gold Cup Isuzu Haima

Product material: Brass + electroplating

Product specification: 2×10×54

Product unit weight: 6.1 g

Product advantages: Easy cutting, easy processing.