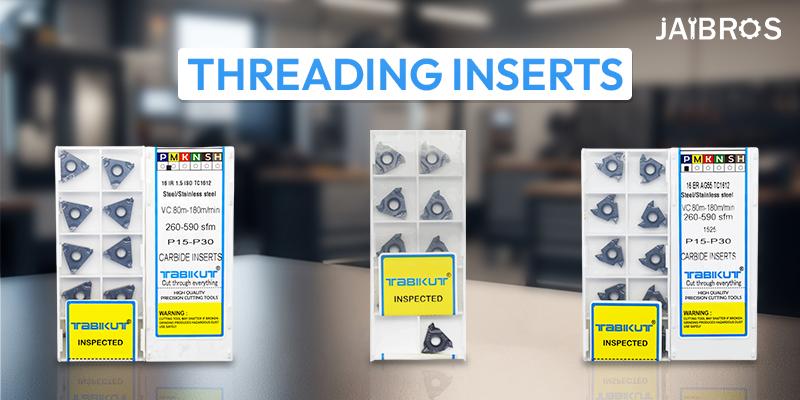

How to Select the Best Threading Inserts for Industrial Use

Premium Threading Inserts for Accurate & Smooth Threading

In modern machining, producing strong, precise, and reliable threads is essential for creating components that fit perfectly and perform under demanding conditions. Whether you’re working in automotive, aerospace, fabrication, or industrial manufacturing, the right threading insert can completely change the quality of your output. Many machinists face issues like chatter, uneven thread profiles, tool wear, or poor surface finish. Most of these problems come down to one simple factor—using low-quality or incorrect inserts.

Premium threading inserts offer exceptional consistency, accuracy, and surface quality. They help maintain precision and extend tool life, making them one of the most valuable assets in CNC turning operations.

Understanding the Role of Threading Inserts in Machining

A threading insert is a replaceable cutting insert designed to cut internal or external threads on a workpiece. Unlike traditional cutting tools, inserts are engineered with precise geometries to match different thread profiles. Their sharp cutting edges, coating technologies, and chip-control designs make them reliable even in high-speed applications.

When machinists choose poor-quality inserts, issues arise such as thread inaccuracy, material tearing, or rapid tool wear. Premium inserts eliminate these problems by ensuring consistent performance throughout long production runs.

Top Reasons Premium Threading Inserts Matter

1. Unmatched Thread Accuracy

Premium inserts are manufactured with strict tolerances, ensuring every pass delivers uniform thread geometry. When a insert performs consistently, the screw and nut pair fit better, reducing vibration and mechanical failures. This level of accuracy is crucial in fields where even a minor error causes functional or safety issues.

2. Extended Tool Life

High-quality inserts use advanced coatings like TiN, TiAlN, or AlTiN, which reduce friction and heat buildup. This means your inserts stay sharp for longer, even during high-speed CNC operations. Longer tool life means fewer changes, reduced downtime, and more uninterrupted machining.

3. Better Surface Finish on Threads

A smooth, polished thread surface improves fastening strength and reduces wear. Premium inserts deliver superior surface finish, eliminating the rough edges you often see with cheaper alternatives. This is especially important for precision industries and high-pressure fluid applications.

4. Reduced Machining Vibrations

Chatter reduces accuracy and damages threads. Premium inserts are perfectly balanced to reduce tool vibration. A stable threading insert ensures deeper passes and cleaner threads with minimal corrections.

5. Versatility Across Materials

Premium inserts are engineered for multiple materials—stainless steel, mild steel, alloy steel, cast iron, and non-ferrous metals. With one set of inserts, machinists can perform threading on a variety of jobs without compromising quality.

Why Threading Accessories Also Matter

Along with inserts, accessories like thread inserts tool and reliable CNC threading insert setups help ensure a complete threading solution. The thread insert tool ensures smooth insert handling and proper alignment. Meanwhile, a high-quality CNC insert ensures the toolholder and machine deliver synchronized cutting for consistent results.

Both of these accessories support the insert and help prevent tool breakage or programming errors. Using the right inserts keeps the process stable and significantly increases the life of the insert and spindle. By choosing a complete threading system, machinists get clean cuts, predictable results, and improved production efficiency.

How Premium Threading Inserts Boost Productivity

Higher Efficiency in CNC Turning

Premium inserts allow machinists to run at faster speeds and deeper passes without compromising thread accuracy. This reduces cycle time and increases production capacity.

Consistent Quality in Every Batch

Whether you produce 10 pieces or 10,000, premium inserts ensure consistency from the first thread to the last. This consistency reduces rework costs and increases customer satisfaction.

Lower Machine Stress

Because premium inserts generate less heat and vibration, the machine’s spindle and toolholder face less stress. This extends the life of your CNC machine and reduces maintenance costs.

Conclusion

Premium inserts are more than just cutting tools—they’re essential components that determine the accuracy, reliability, and strength of your threaded parts. A well-selected insert ensures clean thread formation, reduces tool wear, and achieves perfect results in CNC turning operations. Accessories like thread insert tools and CNC threading insert setups further enhance performance and consistency. Using the right inserts keeps the process smooth and predictable.

At Jaibros, you’ll find a wide range of threading solutions designed for industries that demand precision. Their focus on providing durable, reliable tools helps machinists achieve high-quality results without interruptions. While not promotional, it’s clear Jaibros supports professionals who value accuracy and long-lasting performance.

FAQs

1. What is a threading insert?

A threading insert is a replaceable cutting tool used in CNC turning to create internal or external threads with high precision.

2. Why should I use premium threading inserts?

Premium inserts provide better accuracy, surface finish, and tool life compared to cheaper alternatives.

3. Can threaded inserts be used on different materials?

Yes, premium threading inserts are designed to work on steel, stainless steel, cast iron, and non-ferrous metals.

4. How long does a threading insert last?

Its lifespan depends on speed, material hardness, insert coating, and machining conditions, but premium inserts generally last longer.

5. What affects thread quality the most?

Insert geometry, coating, machine stability, and correct programming all directly impact thread accuracy and smoothness.