How Does a Grinding Wheels Manufacturer Support Industrial Precision?

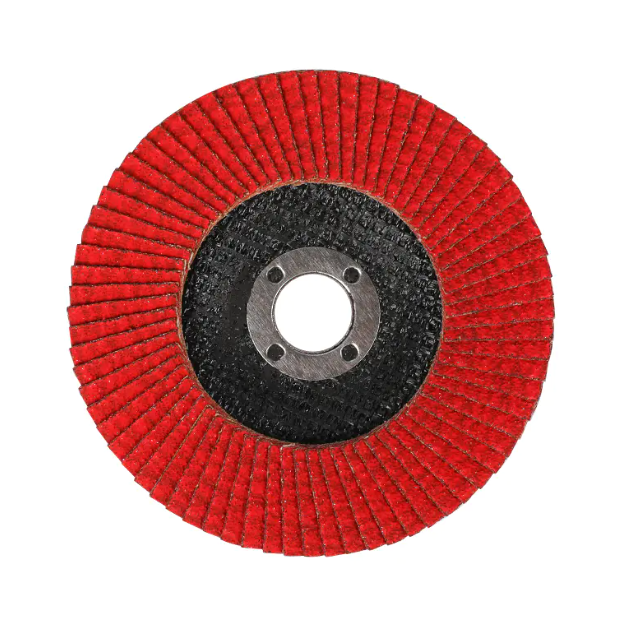

A Grinding Wheels Manufacturer plays a crucial role in industries that rely on precision cutting, shaping, and finishing of materials. Grinding wheels are essential tools in metalworking, woodworking, automotive, and construction sectors. The quality and performance of these wheels directly impact productivity, efficiency, and safety, making the Grinding Wheels Manufacturer a significant contributor to industrial operations.

A professional Grinding Wheels Manufacturer focuses on producing wheels that meet specific performance standards. These wheels can vary in composition, including aluminum oxide, silicon carbide, and diamond grit, depending on the materials they are intended to process. Each wheel is designed for particular applications, whether rough grinding, finishing, or precision shaping. Engineers at the Grinding Wheels Manufacturer carefully select materials and bonding agents to ensure the wheels maintain strength, durability, and consistent performance under high stress.

Production processes in a Grinding Wheels Manufacturer are detailed and precise. Raw materials undergo mixing, molding, and curing to form wheels with specific hardness, grit size, and balance. After molding, wheels are subjected to strict inspection and testing, including concentricity, hardness, and abrasive effectiveness. This ensures that every product leaving the Grinding Wheels Manufacturer maintains consistent quality and reliability for industrial users.

Innovation and research are also vital components of a Grinding Wheels Manufacturer. Factories invest in research to improve the efficiency, lifespan, and safety of grinding wheels. Experimenting with different abrasive combinations and bonding techniques allows manufacturers to create products suited for new materials or specialized industrial applications. Collaboration with machinery manufacturers and industrial clients ensures that the wheels meet practical requirements and adapt to evolving production technologies.

Safety is another major concern for a Grinding Wheels Manufacturer. Improperly manufactured wheels can lead to accidents, so strict quality control is enforced. Safety standards, including those related to wheel strength, rotation speed, and heat resistance, are adhered to during production. Training factory staff and following best practices helps the Grinding Wheels Manufacturer minimize risks while producing reliable industrial tools.

Environmental considerations are becoming increasingly important in modern manufacturing. A Grinding Wheels Manufacturer may incorporate energy-efficient production methods and minimize waste during grinding wheel formation. Recyclable materials and controlled emissions are part of sustainable practices that many manufacturers are adopting. These efforts demonstrate the industry's commitment to balancing performance and environmental responsibility.

The demand for grinding wheels continues to grow as industries require more precise and efficient cutting tools. Manufacturing sectors such as automotive, aerospace, and tool-making depend on reliable grinding solutions to maintain productivity and product quality. A capable Grinding Wheels Manufacturer ensures a steady supply of durable and versatile wheels, supporting these critical industrial processes.

A Grinding Wheels Manufacturer serves as a backbone for precision-based industries. Through careful material selection, precise production, safety compliance, and innovation, these manufacturers provide tools that enhance productivity, reliability, and quality. The ongoing development of grinding wheel technology ensures that the Grinding Wheels Manufacturer remains a vital contributor to industrial efficiency and advancement.