How Do Ferrite Magnet Manufacturers Serve Industrial Applications?

Ferrite Magnet Manufacturers play an essential role in producing magnetic components that are widely used in industries such as electronics, automotive, renewable energy, and consumer appliances. Ferrite magnets are known for their durability, corrosion resistance, and magnetic stability, making them a practical choice for applications ranging from motors and sensors to speakers and magnetic separators. The quality and consistency of products provided by Ferrite Magnet Manufacturers directly affect the performance of these applications.

A typical Ferrite Magnet Manufacturers operation begins with the selection of raw materials. Iron oxide combined with barium or strontium carbonate forms the base for ferrite magnets. The manufacturers carefully control the composition and particle size to achieve consistent magnetic properties. Through precise formulation, Ferrite Magnet Manufacturers can produce magnets with the desired coercivity, remanence, and energy product to suit different applications.

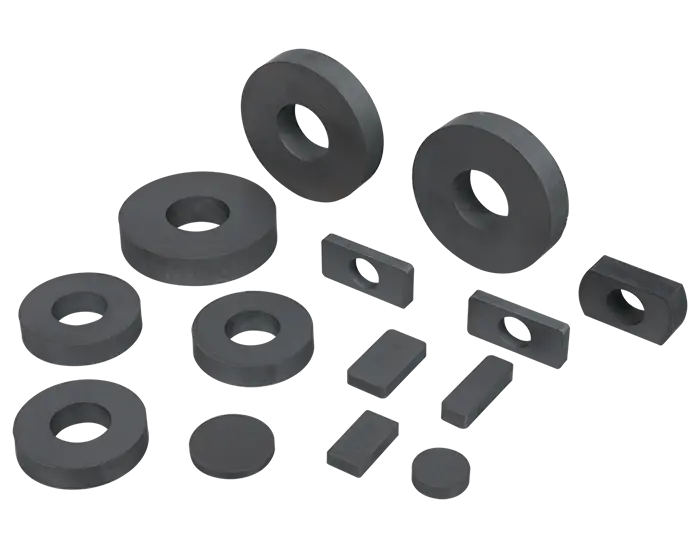

Production techniques are an important aspect of a Ferrite Magnet Manufacturers process. The raw materials are mixed, pressed into the desired shapes, and sintered at high temperatures to form dense and stable magnetic structures. After sintering, the magnets are machined, polished, and magnetized according to specifications. Each step is carefully monitored in a Ferrite Magnet Manufacturers facility to maintain uniformity and reduce defects.

Quality control is a central concern for Ferrite Magnet Manufacturers. Magnets undergo rigorous testing for dimensional accuracy, magnetic strength, and mechanical properties. These tests ensure that the products meet industry standards and perform reliably in their respective applications. By implementing strict quality measures, Ferrite Magnet Manufacturers help clients achieve consistent results in motor efficiency, sensor sensitivity, or electronic device performance.

Customization is another key feature offered by Ferrite Magnet Manufacturers. Different industries require magnets in various sizes, shapes, and magnetic orientations. Manufacturers often provide specialized solutions such as arc-shaped, ring, or block magnets, along with custom coating or surface treatment to enhance durability. This adaptability allows Ferrite Magnet Manufacturers to serve diverse markets, from automotive components to household electronics.

Environmental considerations are increasingly important for Ferrite Magnet Manufacturers. Many manufacturers now adopt energy-efficient sintering techniques and reduce waste during production. By using environmentally responsible practices, Ferrite Magnet Manufacturers contribute to sustainability while maintaining high-quality magnet production.

Applications of ferrite magnets produced by these manufacturers are broad. They are commonly used in electric motors, loudspeakers, magnetic bearings, and various household and industrial appliances. Ferrite Magnet Manufacturers provide reliable products that maintain magnetic performance even in high-temperature or corrosive environments, making them suitable for challenging industrial conditions.

Innovation is also an ongoing focus for Ferrite Magnet Manufacturers. Research into new material compositions, improved magnetic properties, and enhanced machining processes helps meet evolving industry demands. This ensures that manufacturers continue to deliver magnets capable of supporting advanced technologies and modern industrial applications.

Ferrite Magnet Manufacturers are a vital part of the industrial supply chain. By combining careful material selection, precise production techniques, quality control, and customization options, they provide durable and reliable magnets for a wide range of applications. Their role in ensuring consistency, performance, and adaptability makes Ferrite Magnet Manufacturers essential partners for industries that rely on magnetic components.