Advancements Driving the Cerium Oxide Based Polishing Powder Market

The global manufacturing and electronics sectors are increasingly demanding high-quality finishing materials to achieve superior surface properties in precision components. Polishing powders play a crucial role in industries such as optics, glass, semiconductors, and automotive, where the quality of the final product is closely linked to the efficiency of the polishing process. Cerium oxide has emerged as a preferred material for polishing due to its chemical properties and ability to deliver smooth, defect-free surfaces without causing significant material loss. Its applications range from polishing glass lenses and displays to high-precision optical instruments.

The Cerium Oxide Based Polishing Powder Market is experiencing significant adoption as manufacturers look to enhance product quality while maintaining process efficiency. Cerium oxide’s chemical-mechanical polishing (CMP) properties enable it to remove surface defects and improve optical clarity, making it essential for industries requiring precision finishing. The market has benefited from ongoing research into optimizing particle size, shape, and dispersion, allowing for faster polishing rates and improved surface uniformity.

The demand for high-performance glass and optical components is a major factor influencing market growth. Consumer electronics such as smartphones, tablets, and televisions rely on smooth, scratch-free displays, which drives the adoption of cerium oxide-based polishing powders. Additionally, the automotive industry’s push toward advanced glass technologies for windshields, mirrors, and headlamps has created further opportunities for the material. The combination of chemical reactivity and mechanical abrasion offered by cerium oxide allows manufacturers to maintain quality while reducing material consumption.

The Cerium Oxide Based Polishing Powder Market Growth is also driven by innovations in polishing process technology. Automated polishing systems integrated with CMP techniques require uniform and controlled particle distributions, which cerium oxide powders can provide. Enhancements in slurry formulations and polishing pad materials have improved performance, reduced defects, and minimized processing time, allowing manufacturers to achieve higher productivity and lower operational costs.

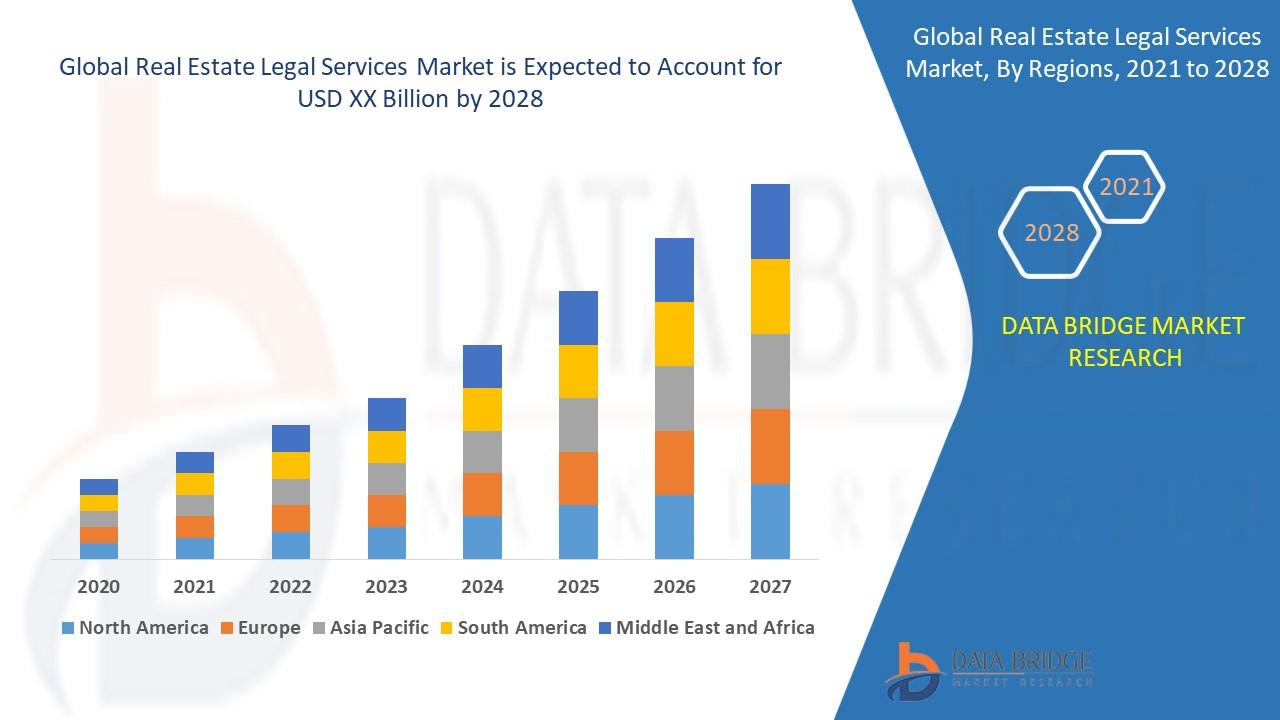

Geographically, Asia-Pacific is a leading region for cerium oxide powder consumption due to its dominance in electronics manufacturing, precision glass production, and automotive industry growth. North America and Europe remain important markets for high-end optical and industrial applications, while emerging regions are gradually increasing their adoption as local manufacturing capabilities expand. The competitive landscape is shaped by companies focusing on product quality, particle consistency, and customer support.

Related Reports:

Two Wheeler Power Train Market

Commercial Roofing Membrane Market

High Speed Citrus Sorting Machine Market

For more in-depth research insights, visit Infinity Market Research.

Stay informed with the latest updates on News Innings, Researcher Diaries, and Industry News Desk.