Should You Really Rely on Inventory Software Alone? Stackerbee Technologies Warns Businesses

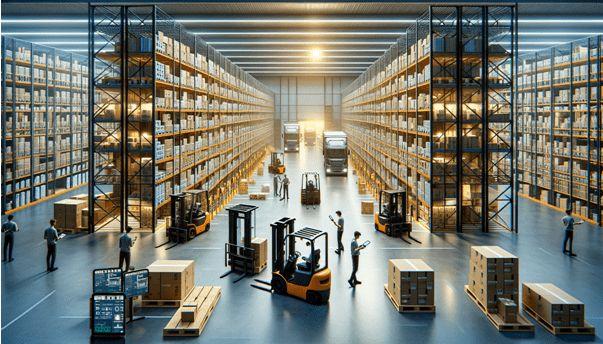

In today’s fast-moving business environment, warehouses are no longer just storage spaces. They are dynamic, technology-driven hubs that directly impact customer satisfaction, delivery speed, and profitability. Many businesses believe that inventory software alone is enough to manage warehouse operations. At first glance, it sounds logical. If you know what stock you have, where it is, and when it moves, what else do you need?

However, this assumption is one of the most common and costly mistakes made by growing businesses.

Stackerbee Technologies warns that relying only on inventory software can limit scalability, reduce operational visibility, and create inefficiencies that remain hidden until they cause real damage. In this article, you will learn the difference between inventory software and a complete Warehouse Management System, why modern warehouses need more than stock tracking, and how businesses in India and globally are upgrading their warehouse technology to stay competitive.

By the end of this guide, you will clearly understand whether inventory software alone is enough — or if a warehouse management system is the smarter long-term solution.

Understanding Inventory Software: What It Does Well

Inventory software focuses primarily on tracking stock levels. It records incoming and outgoing goods, helps prevent stockouts, and gives basic visibility into inventory availability. For small businesses or startups with limited SKUs and low order volume, inventory software can serve as a short-term solution.

Inventory software is designed to answer simple questions:

How much stock is available?

Which products are running low?

When should reordering happen?

In many cases, inventory software works well when warehouse operations are simple and manual processes are manageable. However, as order volumes increase, sales channels expand, and customer expectations rise, cracks begin to appear.

The Limitations of Relying on Inventory Software Alone

Inventory software does not manage warehouse operations holistically. It lacks the intelligence required to control complex workflows, labor efficiency, space utilization, and real-time warehouse tracking.

Businesses often face issues such as delayed order fulfillment, inaccurate picking, inefficient storage layouts, and poor coordination between departments. Inventory software does not optimize picking routes, automate put-away logic, or manage work orders efficiently. It also struggles to support advanced needs like warehouse automation, multi-location management, and e-commerce warehouse management systems.

This is where a warehouse management system becomes essential.

What Is a Warehouse Management System?

A Warehouse Management System (WMS) is a comprehensive warehouse solution that controls and optimizes every aspect of warehouse operations. Unlike basic inventory software, a WMS manages inventory, people, processes, and technology together.

A modern WMS software handles inbound receiving, quality checks, bin allocation, picking strategies, packing workflows, dispatch management, warehouse tracking, and reporting — all from a centralized platform.

Stackerbee Technologies emphasizes that a Warehouse Management System is not just software; it is a strategic tool that improves warehouse optimization, reduces operational costs, and enhances decision-making through real-time data.

Inventory Software vs Warehouse Management Software: The Real Difference

Inventory software answers the question “What do I have?”

Warehouse Management Software answers “How do I move it efficiently?”

A WMS integrates inventory management with warehouse automation, labor management, warehouse tracking, and logistic software management. It ensures that inventory movement is accurate, fast, and optimized at every step.

For businesses handling high order volumes, multiple SKUs, or omnichannel sales, inventory software alone simply cannot keep up.

Why Businesses Are Shifting to Cloud WMS

The rise of cloud-based warehouse management systems has transformed how warehouses operate. Cloud WMS solutions allow businesses to access real-time warehouse data from anywhere, scale operations easily, and reduce infrastructure costs.

Cloud WMS is especially beneficial for businesses in India, where rapid growth in e-commerce and logistics demands flexible and scalable warehouse technology. A cloud-based Warehouse Management System ensures seamless updates, high security, and faster deployment compared to traditional on-premise systems.

Inventory Management in India: A Growing Challenge

India’s supply chain ecosystem is evolving rapidly. With the growth of e-commerce, D2C brands, and third-party logistics providers, warehouses are under pressure to perform faster and smarter.

Many businesses still rely on outdated inventory software, spreadsheets, or semi-manual systems. This often results in inventory mismatches, delayed shipments, and poor customer experience.

Warehouse Management Software in India is becoming a necessity rather than a luxury. Companies that adopt the best Warehouse Management System early gain a strong competitive advantage through better accuracy, faster order processing, and improved scalability.

The Role of Warehouse Automation in Modern Operations

Warehouse automation is no longer limited to large enterprises. Today’s WMS software supports automation features such as barcode scanning, QR codes, automated picking rules, and real-time warehouse tracking.

When inventory software operates alone, automation remains limited. A Warehouse Management System integrates automation into daily warehouse operations, reducing dependency on manual work and minimizing errors.

Stackerbee Technologies highlights that warehouse automation powered by a strong WMS improves productivity, reduces labor costs, and ensures consistent operational performance.

Case Example: When Inventory Software Wasn’t Enough

Consider an e-commerce brand managing thousands of daily orders across multiple marketplaces. Initially, inventory software helped track stock. However, as order volume increased, issues began to surface.

Orders were delayed due to inefficient picking. Returns were hard to track. Warehouse staff spent more time searching for items than fulfilling orders. Inventory accuracy dropped despite having inventory software in place.

After implementing a cloud-based Warehouse Management System, the business gained real-time warehouse visibility, optimized picking routes, and automated dispatch processes. Order accuracy improved significantly, and fulfillment time was reduced by more than 30%.

This example reflects a common pattern seen across industries.

Why WMS Software Is Essential for E-commerce Warehouses

An e-commerce warehouse management system must handle high order frequency, multiple SKUs, and fast turnaround times. Inventory software alone cannot manage peak-season loads, flash sales, or same-day deliveries effectively.

WMS software integrates inventory management with order processing, warehouse tracking, and logistic software management. It ensures smooth coordination between sales channels, warehouses, and delivery partners.

For growing online businesses, the best WMS software becomes the backbone of operations.

Warehouse Optimization Through a Complete WMS

Warehouse optimization is about maximizing space, time, and resources. A Warehouse Management System analyzes warehouse data to improve layout planning, storage strategies, and picking efficiency.

Inventory software does not provide this level of insight. A WMS enables businesses to identify bottlenecks, reduce idle time, and improve overall warehouse operation performance.

This is why the best Warehouse Management Software focuses not only on inventory but also on continuous operational improvement.

Pros and Cons: Inventory Software vs Warehouse Management System

Inventory software is simple, cost-effective, and easy to implement. It works well for small operations with limited complexity.

However, it lacks advanced features, scalability, and operational intelligence.

A Warehouse Management System requires a higher initial investment but delivers long-term value through automation, accuracy, scalability, and data-driven decision-making. For businesses planning growth, a WMS is a future-ready solution.

Frequently Asked Questions

Is inventory software enough for small businesses?

For very small businesses, inventory software may be sufficient initially. However, as order volume and warehouse complexity grow, transitioning to a Warehouse Management System becomes essential.

What is the best Warehouse Management System?

The best warehouse management system is one that aligns with your business size, industry, and growth plans. Cloud-based, scalable, and automation-ready solutions offer the highest value.

Is WMS software relevant in India?

Yes. Warehouse Management Software in India is increasingly important due to rapid growth in logistics, e-commerce, and supply chain modernization.

Expert Insight from Stackerbee Technologies

Stackerbee Technologies emphasizes that businesses should view warehouse technology as a long-term investment rather than a short-term cost. Relying only on inventory software limits growth potential and operational visibility.

A complete Warehouse Management System empowers businesses with real-time data, automation, and control over warehouse operations — making it a critical component of modern supply chains.

Conclusion: Inventory Software Alone Is Not Enough

Inventory software plays an important role, but it is only one piece of the puzzle. As warehouses grow more complex, businesses need a complete warehouse management system to stay efficient, competitive, and scalable.

Stackerbee Technologies warns that relying solely on inventory software can create hidden inefficiencies that slow growth and impact customer satisfaction. A cloud-based, automation-ready Warehouse Management System offers the visibility, control, and intelligence modern businesses need.