What Makes Peripheral Heating Corrugating Roller Design Important in Corrugation Lines?

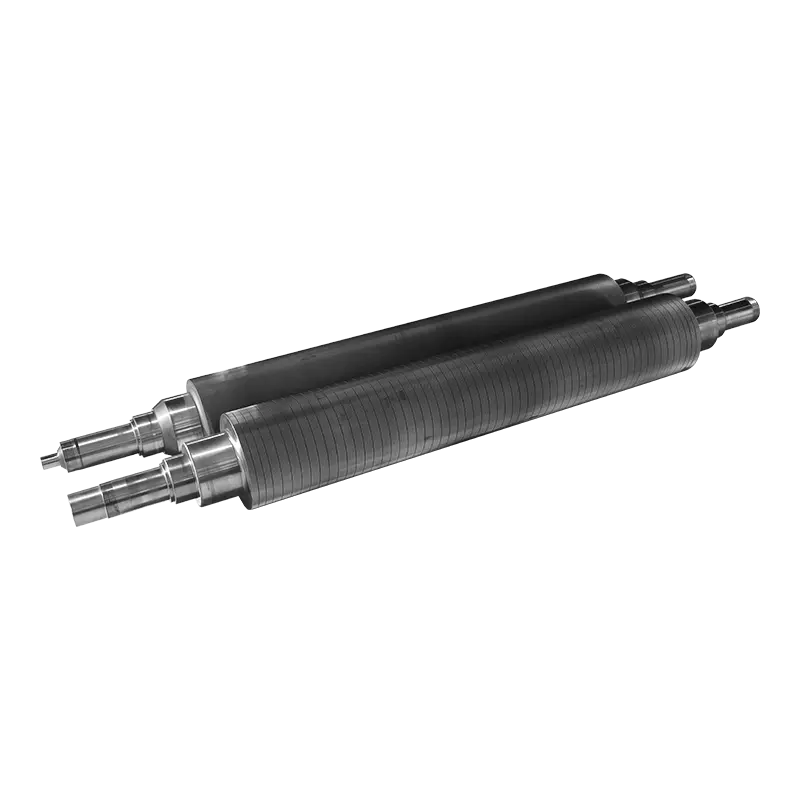

In the corrugated packaging industry, consistent heat transfer and surface stability are essential for forming reliable flute structures. One component closely associated with these requirements is the Peripheral Heating Corrugating Roller, which plays a key role in shaping and bonding corrugated medium during production. Its design and operation influence paper behavior, adhesive activation, and overall line stability.

A Peripheral Heating Corrugating Roller is designed to apply heat evenly around the roller's outer surface rather than concentrating heat at a central point. This approach supports uniform temperature distribution across the working width of the roller. When corrugating medium passes through the nip, consistent surface temperature helps soften fibers evenly, allowing the paper to form flutes without irregular stress or deformation.

The heating method used in a Peripheral Heating Corrugating Roller often involves internal channels or externally controlled systems that transfer thermal energy toward the roller shell. By focusing on the peripheral surface, heat reaches the paper more directly. This design can help reduce temperature fluctuation along the roller face, which is important when operating at steady speeds over extended production cycles.

Material selection is another important aspect of Peripheral Heating Corrugating Roller manufacturing. Roller shells are typically made from alloy steel with carefully controlled hardness and surface finish. These materials are selected to withstand continuous heat exposure, pressure from mating rollers, and repeated contact with paper and adhesive. Surface coatings may also be applied to support wear resistance and maintain consistent flute profiles over time.

In operation, the Peripheral Heating Corrugating Roller works closely with pressure rollers and adhesive systems. Stable heating supports predictable adhesive gelation, which contributes to secure bonding between linerboard and corrugated medium. When heat distribution is uneven, bonding inconsistencies can occur, potentially affecting board strength and downstream converting processes such as die-cutting or folding.

Maintenance considerations are closely tied to roller performance. A Peripheral Heating Corrugating Roller requires regular inspection to ensure heating elements, seals, and surface conditions remain within acceptable ranges. Monitoring surface temperature and checking for wear patterns help operators identify early signs of imbalance or efficiency loss. Proper maintenance supports longer service intervals and stable production planning.

Customization is often required to match specific corrugator configurations. Manufacturers may adjust diameter, flute profile, heating capacity, or surface treatment of a Peripheral Heating Corrugating Roller based on paper grades, line speed, and production goals. This adaptability allows corrugating lines to handle a range of board specifications without major equipment changes.

Energy management is another factor influencing roller selection. By directing heat toward the working surface, a Peripheral Heating Corrugating Roller can support controlled thermal input during operation. This allows operators to adjust temperatures based on paper moisture and ambient conditions, contributing to more predictable process control across different shifts or seasons.

Integration into existing corrugation lines also requires attention to alignment and control systems. The Peripheral Heating Corrugating Roller must be precisely positioned to maintain consistent flute geometry and pressure balance. Coordination with temperature control units and monitoring systems supports steady operation and helps reduce variation in finished board quality.

In summary, the Peripheral Heating Corrugating Roller plays a significant role in corrugated board production by supporting even heat transfer, stable flute formation, and consistent bonding conditions. Through thoughtful design, appropriate material selection, and regular maintenance, this component contributes to reliable corrugator performance. As packaging demand continues to rely on dependable board quality, the role of controlled peripheral heating remains an important part of corrugation technology.

https://www.zjyhroller.com/product/corrugating-rolls/peripheral-heating-corrugating-rolls.html