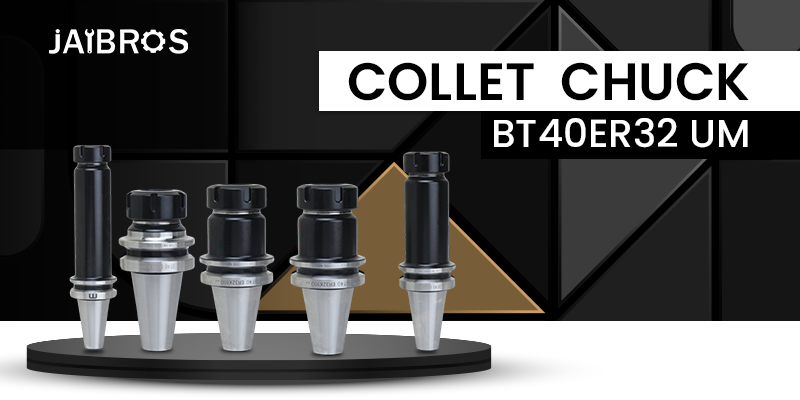

CNC Collet Chuck Tool Holder for High-Speed Performance

CNC collet chuck tool holder designed for high-speed performance, strong gripping force, and precise machining accuracy in CNC applications.

Buy Collet Chuck for CNC & Milling Machines | Durable & Accurate

In modern machining environments, precision and stability are essential for achieving consistent, high-quality results. One of the most critical tool-holding components affecting machining accuracy is the collet chuck. Whether you operate CNC, VMC, or milling machines, choosing the right collet chuck ensures better grip, reduced runout, and improved tool life.

Understanding the Role of a Collet Chuck in Machining

A collet chuck is a mechanical tool-holding device designed to securely grip cutting tools such as end mills, drills, and reamers. It works by compressing a collet around the tool shank, providing uniform clamping pressure and excellent concentricity.

Unlike traditional tool holders, a CNC collet chuck delivers superior holding power and precision, making it ideal for high-speed, high-accuracy machining. This is why collet chucks are widely used across industries such as automotive, aerospace, die and mould, and general engineering.

Why Collet Chucks Are Essential for CNC & Milling Machines

Collet chucks play a vital role in achieving consistent machining results. Their design enables better tool alignment and reduced vibration, directly improving surface finish and dimensional accuracy.

For CNC and milling machines, collet chucks are preferred because they support faster spindle speeds, maintain balance, and provide a strong gripping force even during heavy cutting operations. This combination of strength and precision makes them a reliable choice for both roughing and finishing tasks.

Key Benefits of Using a CNC Collet Chuck

One of the key advantages of a CNC collet chuck is its ability to deliver excellent runout accuracy. Reducing runout leads to better tool performance, longer tool life, and improved part quality.

Another benefit is versatility. Collet chucks can accommodate a wide range of tool diameters by changing the collet, making them cost-effective and adaptable for various machining applications. Additionally, their compact design allows better access to the workpiece, especially in complex milling operations.

Importance of a High-Quality Collet Chuck Holder

The collet chuck holder acts as the interface between the machine spindle and the cutting tool. A well-manufactured holder ensures proper alignment, rigidity, and balance during operation. Poor-quality holders can cause vibration, tool slippage, and uneven cuts, reducing productivity.

High-quality collet chuck holders are made from hardened alloy steel and precision-ground to tight tolerances. This ensures stability even at high RPMs and makes them suitable for demanding CNC applications.

ER Collet Holder and Its Advantages

Among various collet systems, the ER collet holder is one of the most popular choices in CNC machining. ER collets are known for their wide clamping range, allowing a single collet to accommodate multiple tool diameters.

ER collet holders provide strong clamping force, excellent concentricity, and ease of tool change. They are widely used in milling, drilling, tapping, and reaming operations, making them a versatile solution for machine shops and manufacturing units.

Common Collet Chuck Types Used in CNC Machining

Understanding different collet chuck types helps you choose the right tool holder for your specific application. Each type is designed for particular machining needs and performance requirements.

Some collet chucks are optimised for high-speed machining, while others are built for heavy-duty cutting. Selecting the correct type ensures maximum efficiency, safety, and machining accuracy.

ER Collet Chuck Types and Their Applications

ER collet chucks are available in series ER16, ER20, ER25, ER32, and ER40. Each series supports a specific range of tool diameters and is chosen based on spindle size and cutting requirements.

Smaller ER collets are ideal for light machining and precision work, while larger ER collet chucks are suitable for heavy milling and high-torque applications. Their adaptability makes them a preferred choice in CNC workshops.

R8 and Straight Shank Collet Chucks

ER collet chucks are available in series ER16, ER20, ER25, ER32, and ER40. Each series supports a specific range of tool diameters and is chosen based on spindle size and cutting requirements.

Smaller ER collets are ideal for light machining and precision work, while larger ER collet chucks are suitable for heavy milling and high-torque applications. Their adaptability makes them a preferred choice in CNC workshops.

Factors to Consider When Buying a Collet Chuck

Before purchasing a collet chuck, consider machine compatibility, spindle taper, tool diameter range, and application type. Choosing the wrong collet chuck can lead to poor performance and increased tool wear.

Material quality, heat treatment, and precision grinding also play a crucial role in determining durability and accuracy. Always opt for collet chucks that meet industry standards and are sourced from trusted manufacturers or suppliers.

Importance of Choosing Reliable Collet Chuck Suppliers

Selecting the right collet chuck suppliers is just as important as choosing the product itself. Reliable suppliers ensure consistent quality, proper technical support, and availability of standard and custom solutions.

Experienced suppliers offer a wide range of collet chuck holders, ER collet holders, and accessories designed to meet diverse machining needs. Partnering with a trusted supplier helps maintain operational efficiency and long-term reliability.

Applications of Collet Chucks in CNC & Milling Operations

Collet chucks are used across a wide range of machining operations, including milling, drilling, tapping, and boring. Their ability to maintain tight tolerances makes them ideal for precision components and complex geometries.

In CNC machining, collet chucks support automated tool changes and high-speed operations, making them essential for modern manufacturing setups. They are equally effective in small workshops and large-scale production units.

How Collet Checks Improve Machining Accuracy

Accuracy is one of the most critical requirements in CNC machining, and collet chucks directly contribute to it. Their uniform clamping force ensures that tools remain centred and stable during cutting operations.

By minimising vibration and runout, collets help achieve smoother surface finishes and consistent dimensions. This results in fewer reworks, reduced scrap rates, and higher overall productivity.

Maintenance Tips for Long-Lasting Collet Chucks

Proper maintenance extends the life of your collet chuck and ensures consistent performance. Regular cleaning removes chips and debris that can affect clamping accuracy.

Inspecting collets for wear and replacing them when necessary helps maintain grip strength and precision. Using the correct torque during tightening also prevents damage and ensures a safe operation.

Why Collet Chucks Are a Smart Investment

Investing in high-quality collet chucks delivers long-term value by improving machining efficiency and reducing downtime. Their versatility enables use across multiple machines and applications, making them a cost-effective solution.

With better tool holding, increased accuracy, and longer tool life, collet chucks contribute directly to higher profitability and operational excellence.

Company Bio – About Jaibros

Jaibros is a trusted name in the CNC tooling and machine accessories industry, delivering high-precision, durable, performance-driven solutions for modern machining needs. With years of industry experience, Jaibros offers a comprehensive range of CNC tools, collet chuck holders, ER collet holders, cutting tools, and machine accessories, all designed to meet global quality standards.

Driven by a commitment to innovation, quality control, and customer satisfaction, Jaibros partners with manufacturers and engineers to enhance machining accuracy, productivity, and efficiency. Whether for small workshops or large-scale industrial operations, Jaibros remains a reliable partner for precision machining solutions.

Conclusion

Buying the right collet chuck for CNC and milling machines is essential for achieving durable, accurate, and efficient machining results. From understanding different collet chuck types to selecting reliable collet chuck suppliers, every decision affects overall performance.

With the right CNC collet chuck and a trusted brand like Jaibros, manufacturers can ensure superior tool holding, enhanced accuracy, and long-term operational success.