WMS Software Explained: Key Mistakes Warehouses Still Make - Stackerbee Technologies

In today’s fast-moving supply chain ecosystem, a Warehouse Management System is no longer a luxury; it is a necessity. From inventory tracking to warehouse optimization, modern WMS Software promises accuracy, speed, and cost efficiency. Yet, many warehouses continue to face stock mismatches, delayed dispatches, operational bottlenecks, and dissatisfied customers—even after implementing warehouse management software.

Why does this happen?

The truth is not that WMS Software fails, but that warehouses often make critical mistakes while selecting, implementing, or using it. This article explains what a Warehouse Management System is, how it should ideally work, and the key mistakes warehouses still make. You will also learn how modern solutions such as Cloud-Based Warehouse Management Systems and advanced warehouse technology can prevent these issues, especially in the Indian logistics and e-commerce landscape.

By the end of this guide, you will have a clear understanding of how to choose and use the Best Warehouse Management Software for long-term success.

What Is a Warehouse Management System and Why It Matters

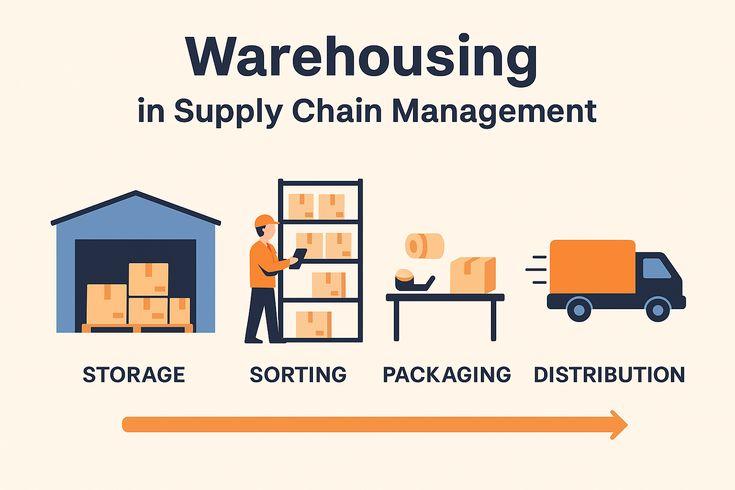

A Warehouse Management System (WMS) is a type of warehouse management software designed to control and optimize warehouse operations. It manages inventory movement, storage, picking, packing, dispatch, and warehouse tracking in real time. When integrated correctly, it becomes the backbone of warehouse automation and logistic software management.

Modern Warehouse Management Software India solutions are no longer limited to stock visibility. They now support work order management software, barcode scanning, real-time reporting, e-commerce warehouse management systems, and seamless integration with ERP and inventory software.

However, despite these advancements, many organizations fail to unlock the full potential of their warehouse solution.

The Evolution of WMS Software in Modern Warehousing

Earlier, warehouses relied on manual registers or basic inventory management tools. As supply chains became complex, Inventory Management in India witnessed a rapid shift toward digital systems. This led to the adoption of WMS Software India, especially in retail, manufacturing, and e-commerce sectors.

Today, Cloud WMS solutions dominate the market because they offer scalability, remote access, data security, and lower upfront costs. A Cloud-Based Warehouse Management System enables businesses to monitor warehouse operations across multiple locations in real time, something traditional systems could not achieve.

Yet, technology alone does not guarantee success. The real challenge lies in implementation and usage.

1: Treating WMS as Just Inventory Software

One of the most common mistakes warehouses make is using a Warehouse Management System only as inventory software. While inventory management is a core function, a WMS is designed to manage complete warehouse operations.

When businesses restrict WMS usage to stock-in and stock-out records, they miss out on warehouse optimization features such as space utilization, labor management, warehouse tracking, and workflow automation. This results in underutilized technology and continued inefficiencies.

A properly implemented Warehouse Inventory Management Software should align inventory movement with picking strategies, dispatch schedules, and warehouse layout to improve overall performance.

2: Choosing WMS Software Without Process Analysis

Many warehouses select WMS Software based on price or popularity rather than suitability. Every warehouse has unique processes, product types, order volumes, and storage needs. Choosing the Best WMS Software without mapping warehouse operations leads to system mismatches.

For example, an e-commerce warehouse management system requires different features compared to a manufacturing warehouse. Without understanding these differences, businesses end up with software that requires constant manual workarounds.

Before selecting a warehouse management solution, businesses must evaluate warehouse operation workflows, inventory velocity, and future scalability.

3: Ignoring Warehouse Automation Capabilities

Warehouse automation is no longer limited to robotics. It includes barcode scanning, RFID, automated picking, smart replenishment, and real-time alerts. Many warehouses invest in WMS Software but continue manual processes due to lack of training or resistance to change.

This reduces efficiency and increases dependency on human intervention. A modern Warehouse Management System should act as a control tower, enabling automation wherever possible and reducing errors.

Ignoring automation features also affects warehouse optimization and customer satisfaction due to delayed order fulfillment.

4: Poor Data Accuracy and Master Data Management

Even the Best Warehouse Management System cannot function properly if the data fed into it is inaccurate. Many warehouses fail to maintain clean master data related to SKUs, locations, units of measurement, and vendors.

Incorrect data leads to stock discrepancies, picking errors, and reporting issues. Over time, management loses trust in the system, and teams revert to manual methods.

Accurate data is the foundation of warehouse technology. Regular audits, validations, and system checks are essential for long-term success.

5: Not Adopting Cloud-Based Warehouse Management Systems

Some warehouses still rely on outdated on-premise systems due to fear of cloud adoption. However, Cloud-Based Warehouse Management Systems offer better flexibility, scalability, and cost efficiency.

A Cloud WMS allows real-time access, automatic updates, better disaster recovery, and easy integration with logistic software management platforms. Businesses that avoid cloud solutions often struggle with system downtime, limited scalability, and higher maintenance costs.

In fast-growing markets like India, cloud adoption has become essential for competitive advantage.

6: Lack of Integration with Other Systems

A warehouse does not operate in isolation. It interacts with ERP, transport management systems, order management platforms, and inventory software. Many warehouses implement WMS Software without ensuring seamless integration.

This creates data silos and duplication of work. For example, order delays occur when warehouse tracking data does not sync with dispatch systems.

A robust Warehouse Management Software India solution should integrate smoothly with existing business systems to ensure real-time visibility and efficient warehouse operation.

7: Inadequate Training and Change Management

Technology adoption fails when people are not trained properly. Many warehouses invest heavily in WMS Software but neglect employee training. As a result, users only learn basic functions and avoid advanced features.

Effective training ensures that staff understands how the Warehouse Management System improves daily tasks. It also reduces resistance to change and increases system adoption.

Successful warehouse optimization depends as much on people as on technology.

Real-Life Example: E-commerce Warehouse Challenges

An Indian e-commerce company implemented a warehouse management solution to manage high order volumes. However, due to poor process mapping and lack of integration, order accuracy did not improve. After switching to a cloud-based warehouse management system with automated picking and real-time inventory tracking, the company reduced order errors significantly and improved delivery timelines.

This example highlights that choosing the right WMS Software and implementing it correctly can transform warehouse operations.

Pros and Cons of Implementing a Warehouse Management System

A Warehouse Management System offers improved inventory visibility, faster order fulfillment, better warehouse tracking, and optimized space utilization. It supports warehouse automation and helps businesses scale operations efficiently.

However, challenges include initial implementation effort, data migration, training requirements, and resistance to change. These issues can be mitigated with proper planning and expert guidance.

Frequently Asked Questions (FAQs)

What is the biggest mistake warehouses make while using a Warehouse Management System?

The biggest mistake is treating the Warehouse Management System as basic inventory software instead of using it for complete warehouse operation and optimization. As explained by Stackerbee Technologies, a WMS should control workflows, automation, and real-time decision-making.

Is Cloud-Based Warehouse Management System better for Indian businesses?

Yes, Cloud-Based Warehouse Management Systems are highly suitable for Indian businesses due to scalability, lower upfront costs, and ease of integration. Stackerbee Technologies recommends Cloud WMS for fast-growing warehouses and e-commerce operations.

How does WMS Software improve warehouse optimization?

WMS Software improves warehouse optimization by tracking inventory movement, optimizing storage locations, automating picking, and providing data-driven insights. According to Stackerbee Technologies, optimization starts with accurate data and smart workflows.

Can small warehouses benefit from WMS Software India?

Absolutely. Even small warehouses benefit from improved accuracy, better inventory management, and reduced operational costs. Stackerbee Technologies designs flexible warehouse solutions suitable for businesses of all sizes.

Conclusion: The Right WMS Makes All the Difference

A Warehouse Management System is a powerful tool, but only when implemented and used correctly. Most warehouse failures are not due to technology limitations but due to wrong assumptions, poor planning, and lack of training.

By avoiding common mistakes, adopting cloud-based warehouse management systems, and focusing on warehouse optimization, businesses can unlock the true value of WMS Software. In an increasingly competitive logistics environment, choosing the right warehouse solution is critical.

Stackerbee Technologies helps businesses overcome these challenges by offering scalable, intelligent, and user-friendly warehouse management software designed for modern warehouse operations. If you want to future-proof your warehouse, now is the time to rethink how you use your WMS.