Why TNMG Tool Holders Are Ideal for Heavy Turning

Discover why TNMG tool holders are ideal for heavy turning, offering high rigidity, better tool life, and stable performance in CNC machining.

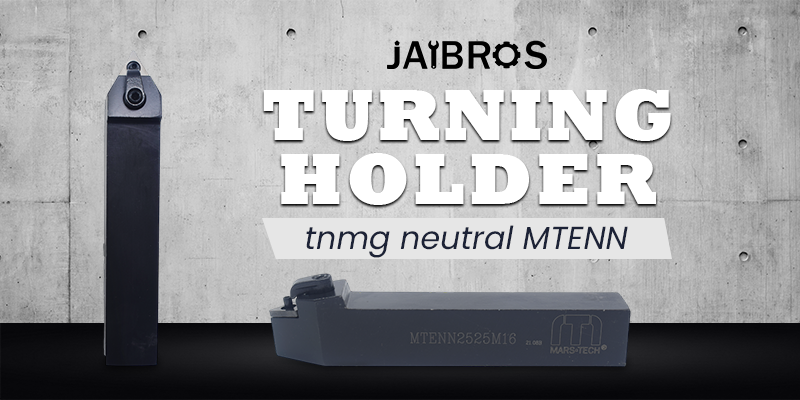

TNMG Tool Holders: The Best Choice for Heavy Turning Operations

Heavy turning operations demand strength, stability, and consistency. When machining hard materials or performing deep cuts, the choice of tooling directly impacts productivity and tool life. One solution that stands out in demanding turning applications is the tnmg tool holder known for its robust design and excellent cutting performance.

Understanding Heavy Turning Operations

Heavy turning involves removing large volumes of material in a single pass. This type of machining is common in industries such as automotive, oil & gas, and heavy engineering. Key challenges include:

-

High cutting forces

-

Increased vibration

-

Heat generation

-

Tool wear and breakage

To overcome these issues, machinists need rigid tooling systems that can handle stress without sacrificing accuracy.

What Makes TNMG Tool Holders Unique?

The popularity of the tnmg tool holder comes from its ability to securely hold triangular negative inserts designed for strength and durability. Unlike positive rake tools, TNMG setups are built to withstand higher loads, making them ideal for rough and semi-rough turning.

The triangular insert design provides multiple cutting edges, improving tool economy while maintaining consistent performance in demanding conditions.

Role of Insert Geometry in Heavy Turning

Insert geometry plays a crucial role in how effectively cutting forces are managed. The tnmg tool angle and overall insert shape distribute pressure evenly across the cutting edge. This reduces localized stress and minimizes the risk of edge chipping during aggressive cuts.

In heavy turning, stable geometry allows machinists to use higher feed rates without compromising surface quality.

Strength and Rigidity for High Load Machining

One of the biggest advantages of a tnmg tool holder is its rigidity. Heavy turning generates intense forces, and any flex in the setup can cause chatter or poor dimensional accuracy.

The rigid clamping mechanism ensures that the tnmg insert tool holder remains stable even under continuous high-load cutting. This stability leads to:

-

Reduced vibration

-

Better dimensional control

-

Longer insert life

Improved Tool Life and Cost Efficiency

Heavy turning tools are subject to extreme wear. The design of the tnmg tool allows machinists to rotate inserts and use multiple edges before replacement. This significantly lowers tooling costs over time.

Additionally, the negative rake geometry supports stronger cutting edges, reducing premature failure and extending tool life in tough materials.

Versatility Across Materials

Another reason machinists prefer the tnmg tool holder is its versatility. It performs well on a wide range of materials, including:

-

Carbon steel

-

Alloy steel

-

Cast iron

-

Stainless steel

By adjusting cutting parameters and selecting the right tnmg angle, operators can optimize performance for different material hardness levels.

Better Control Over Surface Finish

While heavy turning focuses on material removal, surface quality still matters. Proper alignment and correct tnmg tool angle help maintain a consistent cutting path, resulting in improved surface finish even at higher depths of cut.

This makes TNMG setups suitable not only for roughing but also for semi-finishing operations.

Reduced Machine Stress and Downtime

Stable tooling reduces shock loads transmitted to the machine spindle. Using a tnmg tool holder helps protect CNC machines from excessive wear, lowering maintenance needs and reducing unexpected downtime.

This is especially important in high-volume production environments where machine availability directly affects profitability.

Best Practices for Using TNMG Tool Holders

To get the best results in heavy turning:

-

Choose the correct insert grade for your material

-

Maintain proper tool overhang

-

Optimize feed and speed settings

-

Ensure rigid clamping and alignment

Following these practices ensures consistent performance and maximizes the benefits of the tool holder system.

Conclusion

For machinists handling demanding turning operations, the tnmg tool holder proves to be a reliable and cost-effective solution. Its rigid design, strong insert geometry, and ability to handle high cutting forces make it ideal for heavy turning applications.

For businesses looking for dependable CNC tooling solutions, Jaibros offers a wide range of precision-engineered tool holders and inserts designed to meet industrial machining needs. With a focus on quality, performance, and reliability, Jaibros is a trusted choice for professionals seeking long-term machining efficiency.

FAQs

1. What is a TNMG tool holder used for?

It is primarily used for heavy turning and rough machining operations where high cutting forces are involved.

2. Why are TNMG inserts suitable for heavy cutting?

Their negative rake design provides stronger cutting edges and better load distribution.

3. Can TNMG tool holders be used for finishing operations?

They are mainly used for roughing, but with proper settings, they can handle semi-finishing tasks.

4. How does tool angle affect performance?

The correct tool angle improves stability, reduces vibration, and enhances surface finish.

5. Are TNMG tool holders suitable for CNC machines?

Yes, they are widely used in CNC turning centers due to their rigidity and durability.