Hopewayamd Sterilization Self Sealing Pouch for Safe Instrument Storage

In clinical settings where hygiene and handling speed are essential, the Sterilization Self Sealing Pouch from Hopewayamd offers a seamless solution that meets both efficiency and safety standards. Tailored for healthcare professionals seeking convenience without compromising sterilization integrity, this pouch simplifies the packaging process while delivering consistent and secure performance.

The self-sealing design eliminates the need for heat-sealing equipment, making it especially valuable in mobile units, outpatient clinics, and high-turnover environments. Its easy-to-use adhesive strip ensures a tight and reliable closure with minimal effort. This not only saves time but also reduces human error, which can compromise sterility in more traditional sealing methods.

Constructed with durable medical-grade materials, the pouch features a dual-layered composition for maximum protection. One side is transparent, allowing for quick visual verification of contents, while the other provides a breathable surface optimized for effective sterilization methods like steam and gas. The internal surface is engineered to prevent punctures, tears, or fiber shedding during use or transport.

Clear color indicators on the pouch respond to sterilization processes, offering visible confirmation that items have been properly treated. This visual feedback strengthens compliance and record-keeping in regulated environments, aiding both staff and quality control teams. The flat, reinforced seams and evenly distributed adhesive further enhance the reliability of the seal.

Whether used in hospitals, dental offices, or surgical centers, the pouch performs consistently under pressure. Its intuitive design allows staff to focus more on care and less on complex packaging steps. And because it is pre-validated for sterilization compatibility, there's no need for guesswork or compromise when it matters most.

Ready to simplify your sterilization process while keeping safety uncompromised?

Visit https://www.hopewayamd.com/product/ today and discover why modern healthcare facilities choose solutions that seal with confidence.

Nach Verein filtern

Read More

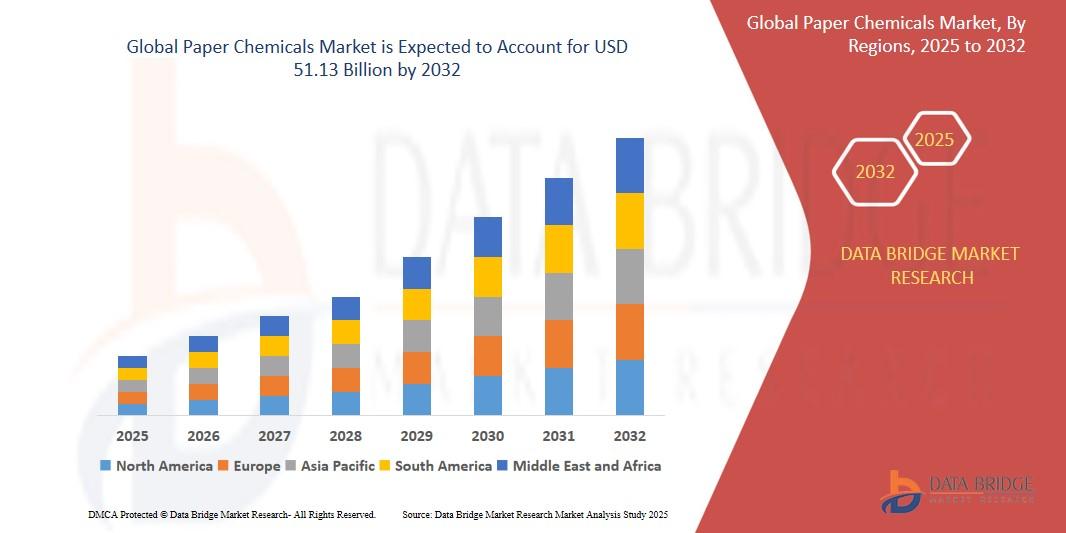

"Regional Overview of Executive Summary Paper Chemicals Market by Size and Share The global Paper Chemicals market size was valued at USD 35.01 billion in 2024 and is expected to reach USD 51.13 billion by 2032, at a CAGR of 4.3% during the forecast period The market report also contains the drivers and restraints for the Paper Chemicals Market that are...

In today’s fast-changing travel industry, Muslims around the world are seeking reliable, luxurious, and well-organized pilgrimage options. Performing Umrah is a deeply spiritual journey, and many pilgrims wish to combine their devotion with comfort and convenience. This is where 5 star Umrah packages make all the difference. Designed for travelers who value both spirituality and premium...

When starting Mounjaro 2.5 mg, most people focus on dosing schedules, weight loss expectations, and side effects like nausea or fatigue. One topic that often gets overlooked—but can make a noticeable difference—is injection site rotation. Many users ask: Does rotating injection sites really affect side effects, or is it just a formality? In this in-depth guide, we’ll explore...

Record-Breaking Boxing Event The Historic Boxing Showdown: Paul vs. Tyson Breaks Viewing Records A landmark sporting event captivated audiences worldwide as Jake Paul faced off against boxing legend Mike Tyson in what became one of the most-watched live streams in history. The unprecedented collaboration between Netflix and Most Valuable Promotions drew an astounding 108 million global viewers,...

"Regional Overview of Executive Summary Synthetic Fibers Market by Size and Share Data Bridge Market Research analyses that the global synthetic fibres market which was USD 65.53 billion in 2022, is expected to reach USD 93.91 billion by 2030, growing at a CAGR of 4.60% during the forecast period of 2023 to 2030. The strategies encompassed in the Synthetic Fibers report mainly include...