Custom Jig and Fixture Design Services for Sports Equipment Manufacturing

The manufacturing of modern sports equipment requires a high level of precision, repeatability, and quality control. From fitness machines and training systems to bicycle components and structural sports hardware, manufacturers must ensure that every part meets strict dimensional and performance requirements. Achieving this level of consistency depends heavily on well-designed manufacturing tools, especially jigs and fixtures tooling which forms the backbone of accurate and efficient production.

While jig and fixture design services are not related to sports activities or athletic performance, they play a vital role in the production and manufacturing of sports equipment. By supporting precise machining, stable assembly, and repeatable results, these tooling solutions enable manufacturers to deliver durable and reliable sports products.

Understanding Jigs and Fixtures in Sports Equipment Manufacturing

Jigs and fixtures are specialized tools used during machining, fabrication, and assembly processes to control the position, movement, and alignment of workpieces.

-

Jigs guide cutting or drilling tools to ensure accurate operations.

-

Fixtures securely hold components in the correct position during machining or assembly.

In sports equipment manufacturing, components often feature complex geometries and tight tolerances. Properly designed jigs and fixtures tooling ensures that each part is manufactured exactly according to design specifications, regardless of production scale.

Why Precision Tooling Is Critical for Sports Equipment Producers

Sports equipment components are frequently exposed to mechanical stress, repeated motion, and load-bearing conditions. Any dimensional variation or misalignment can affect product durability, safety, and functionality. Precision tooling supports manufacturers by ensuring:

-

Accurate and consistent part alignment

-

Repeatable machining and assembly results

-

Reduced human error during production

-

Improved quality control across batches

Custom tooling allows manufacturers to maintain strict standards while meeting production efficiency goals.

Manufacturing Applications Within the Sports Equipment Industry

Custom jig and fixture design services are widely applied across different areas of sports equipment manufacturing, including:

Fitness and Gym Equipment

Gym machines, frames, and support structures require precise machining and assembly. Tooling ensures accurate hole placement, consistent weld alignment, and reliable structural integrity across production runs.

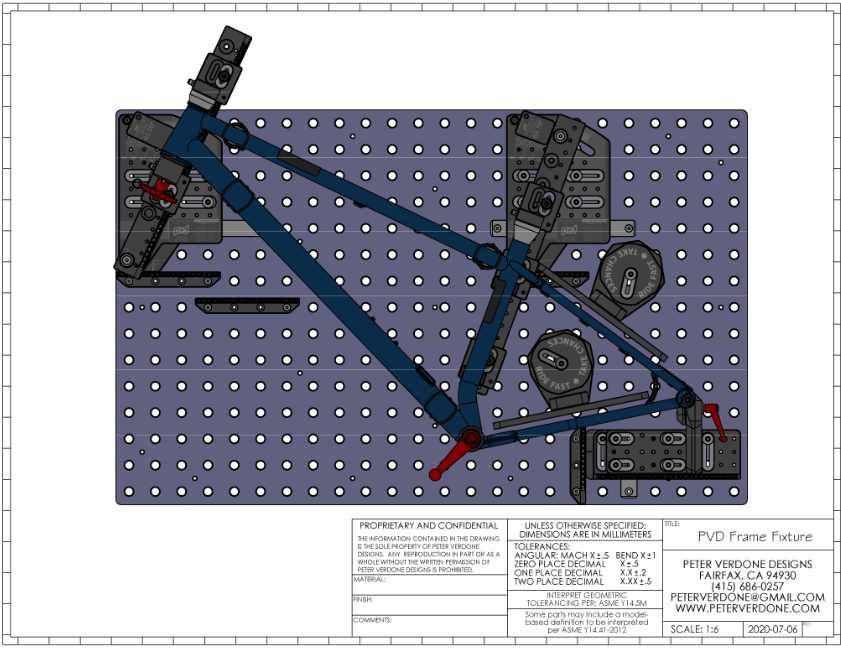

Bicycle Frames and Components

Bicycle manufacturing demands precise geometry and tight tolerances. Custom fixtures help maintain consistent frame dimensions, alignment, and joint accuracy during welding and machining processes.

Training and Conditioning Equipment

Training racks, resistance systems, and functional fitness structures depend on accurately manufactured metal components. Jigs and fixtures tooling ensures uniformity, strength, and repeatability.

Sports Hardware and Structural Accessories

Brackets, mounts, connectors, and metal accessories used in sports equipment benefit from tooling solutions that ensure consistent dimensions and interchangeability.

Custom Tooling Solutions for Specialized Manufacturing Needs

Sports equipment manufacturers often work with unique designs, materials, and production requirements. Standard tooling solutions may not be sufficient. Custom jig and fixture design services provide tailored solutions based on:

-

Component geometry and tolerance requirements

-

Materials such as steel, aluminum, and composite alloys

-

CNC machining, welding, or multi-stage assembly processes

-

Prototype development or full-scale production

By designing tooling specifically for each application, jigs and fixtures tooling enables manufacturers to optimize production efficiency while maintaining consistent quality.

Enhancing Quality, Safety, and Structural Consistency

Safety and reliability are essential considerations in sports equipment manufacturing. Improper alignment or inaccurate machining can compromise structural strength and long-term performance. Precision tooling supports:

-

Stable and accurate part positioning

-

Strong and repeatable joints

-

Reduced defects and rework

-

Improved product durability

Well-designed jigs and fixtures help manufacturers meet safety and quality expectations while reducing manufacturing risks.

Improving Efficiency and Cost Control

Beyond quality improvement, custom tooling also contributes to operational efficiency. Effective jig and fixture solutions provide several production advantages, including:

-

Faster setup and cycle times

-

Reduced reliance on manual adjustments

-

Lower material waste and scrap rates

-

More consistent output across production runs

These benefits allow sports equipment manufacturers to control costs while scaling production efficiently.

Supporting Product Development and Innovation

As sports equipment designs continue to evolve, manufacturers require tooling solutions that can adapt to new concepts and engineering challenges. Custom jig and fixture design supports innovation by enabling:

-

Accurate prototyping and testing

-

Smooth transition from prototype to mass production

-

Consistent results for complex or advanced components

Flexible jigs and fixtures tooling allows manufacturers to bring innovative sports equipment products to market with confidence.

Professional Jig and Fixture Design Expertise

Professional jig and fixture design services combine engineering expertise with hands-on manufacturing experience. By analyzing part design, material properties, and production workflows, tooling solutions are developed to support stable, repeatable, and efficient manufacturing processes.

For sports equipment manufacturers, this expertise is essential to achieving consistent quality, improved efficiency, and long-term production reliability.

Conclusion

Custom jig and fixture design services are a key part of sports equipment manufacturing. Although they are not related to sports activities themselves, these tooling solutions are essential for achieving precision, durability, and consistent product quality during production. Accurate tooling ensures components are manufactured to exact specifications and meet required safety standards.

By supporting reliable machining, stable assembly, and repeatable results, jigs and fixtures tooling helps manufacturers improve efficiency, reduce errors, and ensure long-term product reliability. Additional insights into manufacturing and tooling principles can be found through Wikipedia’s manufacturing overview and Google’s manufacturing technology resources.