Thermal Ceramics Market: Advancements, Applications, and Industry Growth Outlook

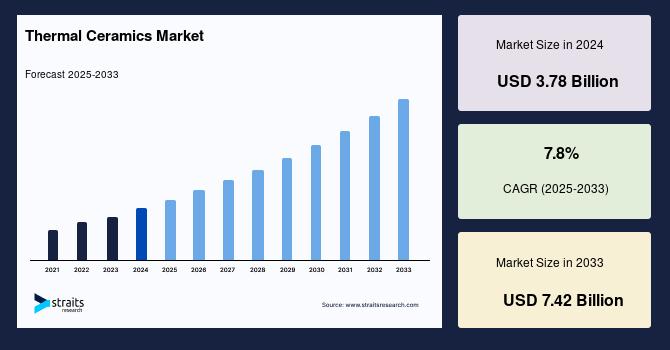

Thermal ceramics represent a specialized class of ceramic materials engineered to withstand extreme temperatures while providing exceptional thermal insulation and resistance to thermal shock. As industrial sectors increasingly demand efficient high-temperature solutions, the thermal ceramics market is experiencing notable growth supported by technological innovations and rising applications across diverse industries. The global thermal ceramics market Size was valued at USD 3.78 billion in 2024 and is projected to reach from USD 4.07 billion in 2025 to USD 7.42 billion by 2033, growing at a CAGR of 7.8% during the forecast period (2025-2033).

Understanding Thermal Ceramics

Thermal ceramics are ultra-high temperature ceramics designed to maintain their mechanical strength and stability even when exposed to temperatures exceeding 2,000°C. Known also as ultra-high temperature refractory ceramics, these materials exhibit low thermal conductivity and excellent thermal shock resistance, enabling them to serve as effective insulators in harsh thermal environments. Their chemical stability and resistance against acidic and alkaline substances further expand their usability across numerous high-temperature industrial applications.

Growth Drivers of the Thermal Ceramics Market

A significant driver for thermal ceramics demand is their application in energy-related industries, including oil and gas, solar power generation, and chemical processing. Thermal ceramics enhance solar panel efficiency by providing superior insulation that minimizes heat loss, thereby boosting energy conversion rates in photovoltaic systems. The rise in global solar energy adoption acts as a catalyst for expanding the thermal ceramics market size.

Another prominent growth factor is the surge in infrastructure development, particularly in the Asia-Pacific region, where expanding construction activities call for advanced materials like thermal ceramics. These materials are extensively used in building insulation, lining furnaces, kilns, and reactors, ensuring thermal management and operational efficiency in construction, metallurgical, and manufacturing sectors.

Applications and End-Use Segments

The market is segmented broadly into ceramic fibers and insulation bricks, which dominate due to their distinct properties and usage flexibility. Ceramic fibers are valued for being lightweight, flexible, and excellent thermal insulators that resist thermal shock and corrosion. They are commonly employed in industries such as aerospace, oil and gas, chemicals, and metal processing for fire protection, furnace linings, and sealing applications.

Insulation bricks provide structural integrity combined with superior heat resistance and are frequently used in steel production, non-ferrous metal processing, and glass manufacturing. These bricks serve as hot-face linings and supplementary insulation, contributing to energy savings and enhanced equipment durability.

Among industrial end uses, mining and metal processing hold a leading market share due to their reliance on furnaces and kilns requiring advanced thermal insulation. The chemical and petrochemical industry also constitutes a significant segment, leveraging thermal ceramics for furnace linings and as high-temperature sealing materials critical in various thermal processes.

Regional Market Dynamics

North America commands the largest market share driven by established manufacturing bases and robust aerospace and defense sectors requiring sophisticated thermal ceramics. Government investments in space exploration and increasing applications in hypersonic weaponry contribute to market strength in the region.

Asia-Pacific is the fastest-growing market, with China, India, Vietnam, and Indonesia leading infrastructural developments and industrial expansions. The rising demand for chemicals and petrochemicals in this region further propels growth, supported by government initiatives to reduce imports and boost domestic production capabilities.

Challenges and Market Restraints

Despite the promising outlook, the thermal ceramics market faces challenges including environmental concerns and health risks related to ceramic fibers, which have been studied for potential carcinogenic effects. The industry is responding by innovating low bio-persistent materials that mitigate health hazards and environmental impacts.

Additionally, high raw material costs, complex installation processes, and the economic sensitivity of end-use industries may pose barriers to market growth. However, industry players continue to focus on technological advancements and eco-friendly product development to overcome these constraints.

Future Outlook

The thermal ceramics market is poised for robust growth with a projected compound annual growth rate of around 7.8% from 2025 to 2033. Innovation in nanotechnology and composite materials is anticipated to expand application horizons, including electric vehicle batteries and sustainable building solutions. As industries prioritize energy efficiency and regulatory compliance, thermal ceramics will remain integral to high-temperature insulation needs across multiple sectors.

In conclusion, thermal ceramics play an essential role in modern industrial applications requiring durable, efficient, and environmentally aware thermal management solutions. The market's growth is fueled by increasing energy demands, infrastructure development, and technological advancements, positioning thermal ceramics as a critical material for future industrial progress.