How Knurling Tool Improves Grip & Surface Finish in Machining

Learn how a knurling tool enhances grip and surface finish in CNC machining. Explore benefits, CNC applications, and knurling tool price factors.

Knurling Tool Benefits for Better Grip & Surface Finish

In precision machining, surface quality and functional grip play a vital role in the performance of mechanical components. Many parts may look complete after turning or milling, but without proper surface treatment, they can lack usability or safety. This is where a knurling tool becomes essential. Knurling is not just a decorative process—it significantly improves grip, enhances appearance, and adds functional value to cylindrical components.

From hand-operated knobs to high-precision industrial parts, knurling is widely used across machining applications.

What Is Knurling and Why Is It Important?

Knurling is a machining process that creates patterned ridges on the surface of a workpiece, usually on cylindrical parts. These ridges increase friction, making parts easier to grip by hand or tool. Unlike cutting operations, knurling is a forming process where material is displaced rather than removed.

A knurling tool presses hardened wheels with specific patterns into the rotating workpiece. As pressure is applied, the metal flows to form straight, diagonal, or diamond-shaped patterns. This process is commonly performed on the machines and CNC turning centres.

Knurling is especially important in applications where parts are frequently handled, tightened, or adjusted manually. It also helps improve assembly efficiency by preventing slippage between mating components.

How Knurling Improves Grip Performance

One of the primary reasons for knurling is enhanced grip. Smooth metal surfaces can be slippery, especially when exposed to oil, grease, or moisture. Knurled patterns solve this problem by increasing surface friction.

Increase Friction for Better Handling

The raised ridges formed during knurling create multiple contact points for fingers or tools. This makes components like knobs, handles, and adjustment screws easier to hold and turn.

Improved Safety

In industrial environments, operators often work with gloves. Knurled surfaces reduce the risk of slipping, minimizing accidents during operation or maintenance.

Consistent Torque Application

Knurled components allow users to apply consistent torque without excessive force. This is crucial in precision assemblies where overtightening can damage parts.

Role of Knurling in Surface Finish Enhancement

Beyond grip, knurling also improves the visual and functional quality of a component’s surface. While it may seem counterintuitive, patterned surfaces often perform better than smooth ones in specific applications.

A tool creates uniform, repeatable textures that enhance the overall appearance of machined parts. Well-executed knurling gives components a professional and high-quality finish.

Masking Minor Surface Defects

Knurled patterns can conceal minor machining marks, scratches, or tool lines left from previous operations.

Improved Wear Characteristics

Textured surfaces can hold lubricants more effectively, reducing wear in moving or rotating components.

Aesthetic Value

In consumer-facing products, knurled finishes add a premium look, especially in knobs, dials, and control components.

Types of Knurling Patterns and Their Applications

Different knurling patterns are used depending on functional requirements and design preferences.

Straight Knurling

Features parallel ridges along the axis of the part. Commonly used for light grip applications and decorative finishes.

Diamond Knurling

Creates a crisscross pattern offering superior grip. Widely used in industrial and mechanical components.

Diagonal Knurling

Provides directional grip and is often used in specialized applications.

Selecting the right pattern ensures optimal grip and surface performance without compromising dimensional accuracy.

Knurling in CNC Machining Applications

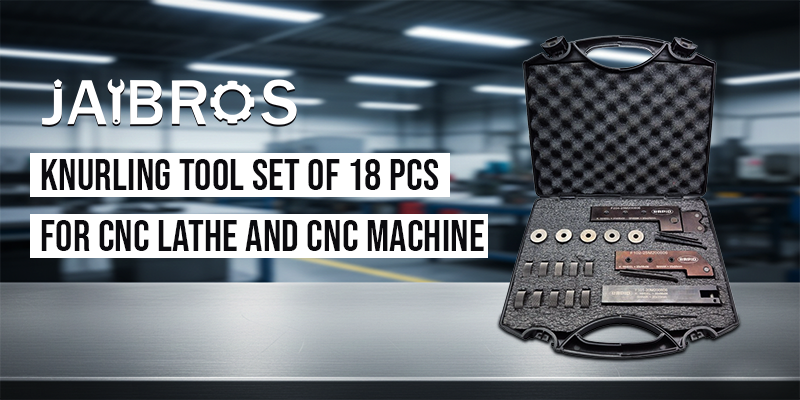

With the advancement of automation, knurling has become a standard operation in CNC environments. A knurling tool for CNC turning is designed to maintain consistent pressure and alignment, ensuring uniform patterns even at high production volumes.

Using a knurling for CNC setups allows manufacturers to achieve repeatability and precision that manual machining cannot always guarantee. CNC knurling is especially beneficial for batch production, where consistency is critical.

A CNC knurling integrates seamlessly into CNC turning programs, reducing cycle time and eliminating the need for secondary operations. Proper programming ensures controlled feed rates and pressure, preventing tool wear and workpiece damage.

Factors That Affect Knurling Quality

Several variables influence the effectiveness of knurling:

Material Type

-

Softer materials like aluminium and brass form knurls easily, while harder materials require precise pressure control.

-

Feed and Speed

-

Incorrect feed rates can cause double tracking or uneven patterns.

-

Tool Alignment

-

Misalignment leads to distorted knurls and poor surface finish.

A high-quality knurling tool combined with proper setup ensures clean, well-defined patterns with minimal effort.

Knurling Tool Price and Cost Considerations

When evaluating knurling solutions, knurling tool price depends on several factors:

-

Tool material and hardness

-

Single-wheel vs multi-wheel design

-

Compatibility with CNC or manual machines

-

Brand and manufacturing quality

While lower-cost options may work for light applications, investing in a durable tool often results in better surface finish, longer tool life, and reduced downtime. For CNC environments, precision-engineered tools offer better consistency and reduced scrap rates.

Best Practices for Achieving Optimal Knurling Results

To get the best grip and surface finish:

-

Ensure proper tool alignment before starting

-

Use adequate lubrication to reduce friction

-

Apply consistent pressure throughout the operation

-

Match knurl pitch with workpiece diameter

Using the right knurling tool setup minimizes material deformation and ensures clean, professional-looking results.

Common Knurling Challenges and Solutions

Even experienced machinists may encounter knurling issues.

Double Tracking

Occurs when the knurl pitch doesn’t match the workpiece circumference. Solution: adjust diameter or select a suitable pitch.

-

Poor Definition

-

Caused by insufficient pressure or dull wheels.

-

Surface Tearing

-

Often due to excessive speed or lack of lubrication.

A well-maintained knurling tool significantly reduces these problems.

Conclusion

Knurling is more than just a surface treatment—it’s a functional enhancement that improves grip, safety, and product quality. Whether used in manual machining or CNC turning, the right approach ensures consistent patterns and excellent surface finish.

By understanding material behavior, selecting proper tooling, and following best practices, manufacturers can achieve reliable results across various applications. A high-quality cnc tool is a valuable investment for any machining operation focused on performance and precision.

FAQs

1. What is the main purpose of knurling in machining?

Knurling improves grip, enhances surface finish, and adds functional texture to cylindrical components.

2. Can knurling be done on CNC machines?

Yes, knurling is widely performed on CNC turning centers using specially designed tools for precision and repeatability.

3. Does knurling remove material?

No, knurling is a forming process where material is displaced, not cut.

4. Which materials are best suited for knurling?

Aluminum, brass, mild steel, and stainless steel are commonly knurled materials.

5. How do I choose the right knurling pattern?

The choice depends on grip requirements, aesthetics, and application—diamond patterns offer maximum grip, while straight patterns are used for lighter applications.