Efficiency Factors of a Distribution Transformer in Grids

Electricity plays a crucial role in our daily lives. From lighting homes to running industries, it is the backbone of modern society. At the heart of the electricity distribution network lies the distribution transformer. These transformers are essential for delivering electrical energy safely and efficiently from power stations to homes, offices, and factories. Understanding how distribution transformers work and what affects their efficiency can help utilities, engineers, and even consumers ensure better performance and lower energy losses.

In this article, we will explore the key factors that determine the efficiency of a distribution transformer in electrical grids. We will also discuss how these factors can be optimized for better performance. By the end, you will have a clear understanding of the importance of transformer efficiency and how it impacts the overall power supply.

What is a Distribution Transformer?

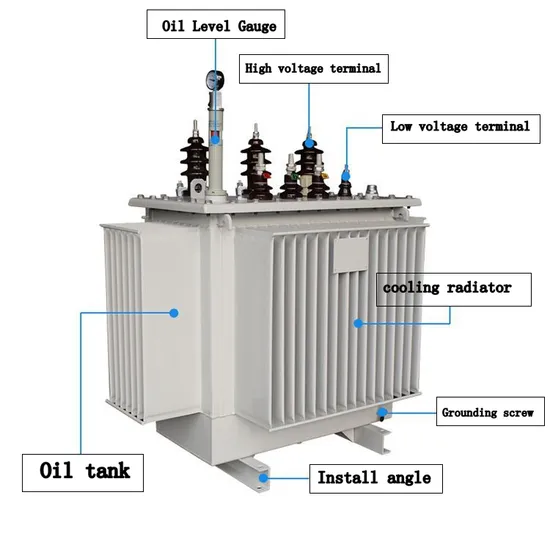

A distribution transformer is a type of electrical transformer used to step down high voltage electricity from the grid to a lower voltage suitable for residential, commercial, or industrial use. For example, it converts 11 kV or 33 kV from the transmission network to 230 V or 400 V used in homes and small businesses.

Distribution transformers are typically installed near consumption points and are designed to operate continuously for long periods. They are smaller than power transformers used in transmission lines but are equally important in ensuring a reliable power supply.

Key features of a distribution transformer include:

-

Step-down voltage conversion: Converts high voltage to low voltage.

-

Continuous operation: Designed to run 24/7 with minimal interruptions.

-

Load adaptability: Can handle varying loads depending on consumption needs.

The efficiency of a distribution transformer determines how much of the electrical energy entering the transformer reaches the end users without being lost as heat or other forms of energy.

Why Efficiency Matters in Distribution Transformers

Efficiency in a distribution transformer refers to the ratio of output power to input power. Simply put, it measures how well the transformer converts incoming electricity into usable electricity at the output. Higher efficiency means more electricity reaches consumers with minimal losses.

Here’s why efficiency is crucial:

-

Reduced Energy Losses: Every transformer experiences some energy loss, mainly as heat. Efficient transformers minimize these losses, saving electricity and reducing overall costs.

-

Lower Operating Costs: Less energy loss means the utility spends less on energy generation to compensate for lost power.

-

Longer Lifespan: Efficient transformers operate at lower temperatures, reducing wear and tear on components and extending operational life.

-

Environmental Benefits: Reduced energy losses mean less fuel consumption in power plants, which translates to lower greenhouse gas emissions.

For all these reasons, utilities and engineers pay close attention to factors that influence distribution transformer efficiency.

Factors Affecting Distribution Transformer Efficiency

Several factors determine the efficiency of a distribution transformer. Understanding these factors helps in designing, selecting, and maintaining transformers for optimal performance.

1. Core Material and Construction

The core of a transformer is made of magnetic material, usually silicon steel laminations. The quality and type of steel used in the core significantly affect efficiency.

-

High-quality silicon steel reduces hysteresis loss, which occurs due to magnetization and demagnetization of the core.

-

Lamination thickness: Thin laminations reduce eddy current losses. Thicker laminations increase resistance and energy losses.

-

Core design: Toroidal cores often have higher efficiency than traditional rectangular cores due to reduced magnetic leakage.

2. Load Factor

Efficiency varies depending on the transformer’s load. Most transformers achieve their highest efficiency when operating near full load, but the load on distribution transformers is rarely constant.

-

Light-load operation: Efficiency drops at low loads because fixed losses, like core losses, remain constant regardless of output.

-

Peak-load operation: Efficiency is higher near rated load but may generate more heat, requiring proper cooling.

Understanding the typical load profile of the area helps in selecting a transformer that maintains good efficiency under expected operating conditions.

3. Copper and Conductor Losses

The winding conductors of a transformer are usually made of copper or aluminum. Resistance in these windings causes copper losses, which increase with the square of the load current.

-

High-quality copper windings: Reduce resistance and copper losses.

-

Proper conductor sizing: Oversized conductors reduce losses but increase cost.

-

Temperature management: High temperatures increase resistance, further increasing copper losses.

Minimizing copper losses is essential for maintaining efficiency, especially in areas with fluctuating loads.

4. Cooling and Ventilation

Transformers generate heat due to losses in the core and windings. Efficient cooling ensures that the transformer operates within safe temperature limits, preventing additional losses or damage.

-

Oil-immersed transformers use insulating oil for cooling and insulation.

-

Air-cooled transformers rely on ambient airflow or fans to remove heat.

-

Proper cooling not only maintains efficiency but also prolongs the lifespan of insulation and core material.

5. Voltage Regulation

Voltage regulation refers to the ability of the transformer to maintain constant output voltage under varying load conditions. Poor voltage regulation can result in higher losses and reduced efficiency.

-

Transformers with better voltage regulation have lower internal losses.

-

Correct sizing ensures that the transformer does not operate at excessively low or high voltages, which can increase losses.

6. Transformer Size and Design

Efficiency is also influenced by the transformer’s design and rating. Small transformers may have lower efficiency at certain loads due to higher relative losses. Conversely, properly sized transformers achieve optimal efficiency near their rated capacity.

-

Oversized transformers: Operate at light loads most of the time, reducing efficiency.

-

Undersized transformers: Operate under high loads, causing overheating and higher losses.

Selecting the right size based on expected load is crucial for maintaining efficiency.

7. Environmental Conditions

Temperature, humidity, and dust can indirectly affect transformer efficiency. High ambient temperatures increase winding resistance, causing higher copper losses. Dust accumulation can reduce cooling efficiency, leading to overheating. Proper maintenance and installation in suitable environments improve overall efficiency.

Measuring Distribution Transformer Efficiency

Efficiency can be expressed mathematically as:

Efficiency (%)=Output PowerInput Power×100\text{Efficiency (\%)} = \frac{\text{Output Power}}{\text{Input Power}} \times 100Efficiency (%)=Input PowerOutput Power×100

Where:

-

Input Power = Total electrical energy supplied to the transformer

-

Output Power = Electrical energy delivered to the load

Efficiency is influenced by two main types of losses:

-

No-load Losses (Core Losses)

-

Occur when the transformer is energized but not delivering power.

-

Caused by hysteresis and eddy currents in the core.

-

-

Load Losses (Copper Losses)

-

Occur when the transformer delivers current to the load.

-

Depend on winding resistance and load current.

-

The goal in transformer design is to minimize both core and copper losses while keeping costs reasonable.

Improving Efficiency of Distribution Transformers

Utilities and manufacturers use several methods to improve transformer efficiency:

-

Using high-quality core materials: Reduces core losses.

-

Optimizing winding design: Minimizes copper losses.

-

Proper transformer sizing: Ensures operation near optimal load.

-

Enhanced cooling systems: Maintains safe operating temperatures.

-

Regular maintenance: Cleaning, oil checks, and thermal monitoring prevent efficiency degradation.

Additionally, advances in transformer technology, such as amorphous steel cores and improved insulation materials, have further enhanced efficiency in modern distribution transformers.

Real-World Implications

Efficient distribution transformers have a direct impact on the energy sector and the economy. Some benefits include:

-

Lower electricity bills for consumers due to reduced losses.

-

Reduced energy generation requirements for utilities, saving fuel and reducing emissions.

-

Improved reliability of the grid as transformers operate within safe limits for longer durations.

-

Support for renewable energy integration, as efficient transformers handle fluctuating loads from solar or wind power better.

Investing in high-efficiency transformers may have higher upfront costs, but the long-term savings and environmental benefits make it worthwhile.

Conclusion

The efficiency of a distribution transformer manufacturers in assam is influenced by several factors, including core material, load factor, winding losses, cooling, voltage regulation, design, and environmental conditions. Understanding these factors helps engineers, utilities, and consumers ensure reliable and cost-effective electricity delivery.

For households, industries, and communities looking for reliable electricity solutions, choosing transformers with high efficiency is crucial. Providers like Prabha Power offer advanced distribution transformer solutions that balance performance, durability, and energy efficiency, ensuring a stable and sustainable power supply for all users. By focusing on efficiency, we can reduce energy losses, save costs, and contribute to a greener future.