CNC Aluminum Prototype Manufacturing for Innovative Designs

In the aerospace industry, success depends on precision, reliability, and seamless execution across every stage of manufacturing. From early-stage development to full-scale production, Spartan Aerospace delivers end-to-end solutions that support critical mission aerospace programs. By combining prototype CNC aluminum prototype, advanced precision investment casting, and high-accuracy aerospace precision machining, Spartan Aerospace provides a fully integrated manufacturing approach designed to meet the industry’s most demanding requirements.

Precision Aluminum Casting for Aerospace Applications

Aerospace components require exceptional dimensional accuracy, structural integrity, and material consistency. Precision aluminum casting plays a vital role in producing complex geometries while maintaining tight tolerances. Spartan Aerospace leverages proven casting processes to manufacture lightweight, high-strength aluminum components optimized for aerospace performance.

Using aerospace-grade aluminum alloys, Spartan Aerospace ensures each casting meets mechanical, thermal, and fatigue resistance standards essential for flight-critical applications. From structural brackets to intricate housings, aluminum cast components are engineered to perform reliably in extreme environments.

Expertise in Aluminum Investment Casting

Aluminum investment casting is a cornerstone of Spartan Aerospace’s manufacturing capabilities. This process enables the production of near-net-shape components with excellent surface finish and fine detail, reducing the need for extensive secondary operations. Spartan Aerospace’s precision investment casting techniques support both low-volume prototypes and scalable production runs while maintaining consistent quality.

By carefully controlling mold design, alloy selection, and solidification parameters, Spartan Aerospace produces castings that meet aerospace tolerances and performance specifications. This level of process control is critical for components used in safety-critical and mission-essential aerospace systems.

Prototype Aluminum Casting for Rapid Development

Innovation in aerospace begins with rapid and accurate prototyping. Spartan Aerospace specializes in prototype aluminum casting, enabling engineers to validate designs, test performance, and accelerate development timelines. Early-stage casting allows for realistic evaluation of form, fit, and function before transitioning to full production.

This capability supports faster design iteration, reduced development risk, and improved cost efficiency for aerospace programs. By integrating prototype casting into the manufacturing workflow, Spartan Aerospace helps customers move confidently from concept to qualification.

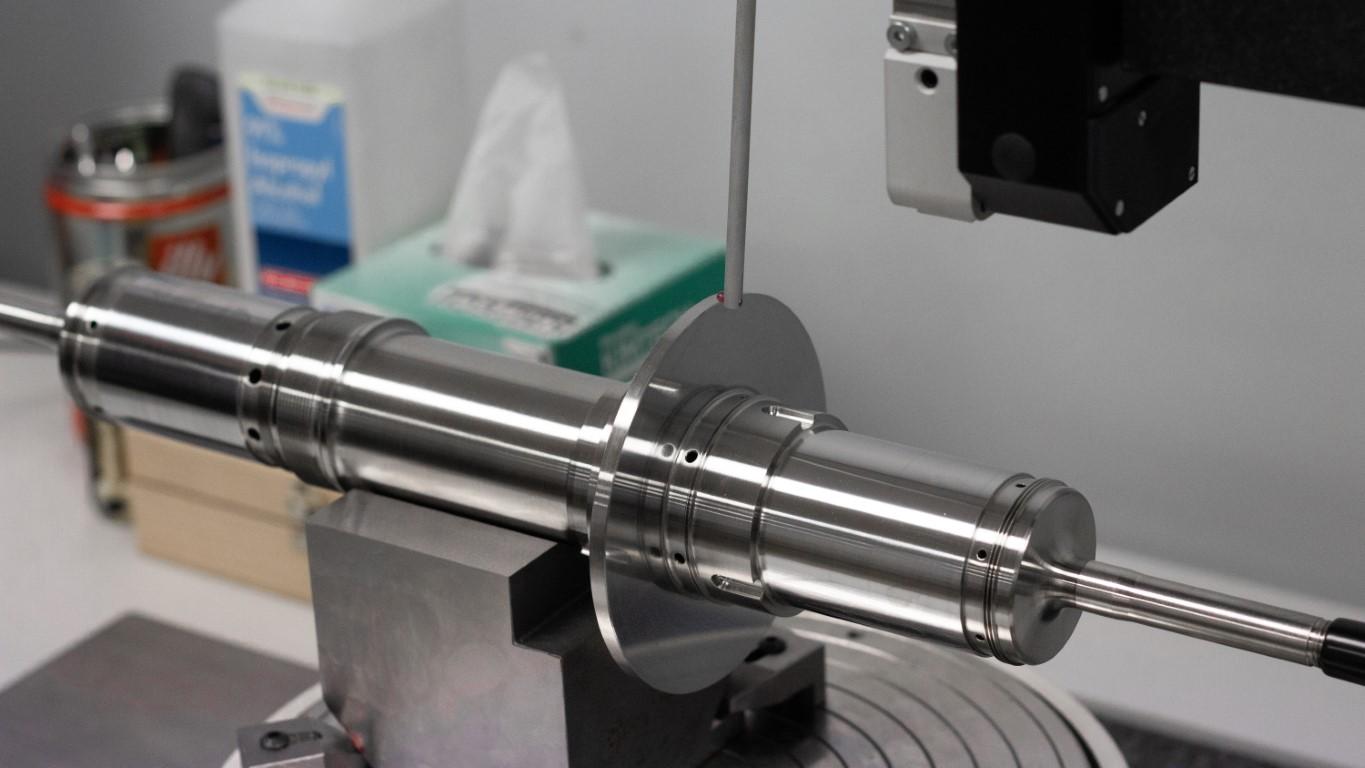

CNC Aluminum Prototype and Aerospace Precision Machining

Following casting, components often require high-precision finishing to meet exact aerospace specifications. Spartan Aerospace delivers advanced aerospace precision machining using state-of-the-art CNC equipment. From tight-tolerance drilling and milling to complex multi-axis machining, every operation is optimized for accuracy and repeatability.

The company also supports CNC aluminum prototype machining, allowing rapid refinement of cast or billet components during development phases. This combination of casting and machining expertise ensures dimensional precision, superior surface quality, and consistent performance across all production stages.

Integrated Manufacturing for Mission-Critical Programs

What sets Spartan Aerospace apart is its integrated manufacturing approach. By uniting precision aluminum casting, aluminum investment casting, and aerospace precision machining within a coordinated production framework, Spartan Aerospace minimizes supply chain complexity and enhances quality control.

This integration offers significant advantages:

-

Reduced lead times from prototype to production

-

Improved communication between engineering and manufacturing

-

Enhanced traceability and process consistency

-

Greater flexibility to accommodate design changes

For critical mission aerospace programs, this streamlined model delivers reliability, predictability, and performance confidence.

Commitment to Quality and Performance

Every component produced by Spartan Aerospace is subject to rigorous quality standards. Inspection processes, dimensional verification, and documented quality systems ensure compliance with aerospace regulations and customer requirements. This commitment to excellence reduces risk and ensures long-term reliability in service.

A Trusted Partner in Aerospace Manufacturing

As aerospace platforms become more advanced, manufacturers require partners capable of supporting complex designs and accelerated timelines. Spartan Aerospace continues to invest in technology, expertise, and process optimization to support next-generation aerospace systems.