Precision Investment Casting for High-Performance Manufacturing

In industries where performance, accuracy, and reliability are essential, manufacturers need partners who can deliver consistent quality from concept through production. At Integra-Cast, we specialize in providing assembly-ready Precision investment casting through a comprehensive range of integrated manufacturing services. Our capabilities include aluminum CNC machining, aluminum investment casting, precision investment casting, and advanced aluminum prototyping services, enabling customers to streamline development and production while maintaining uncompromising standards.

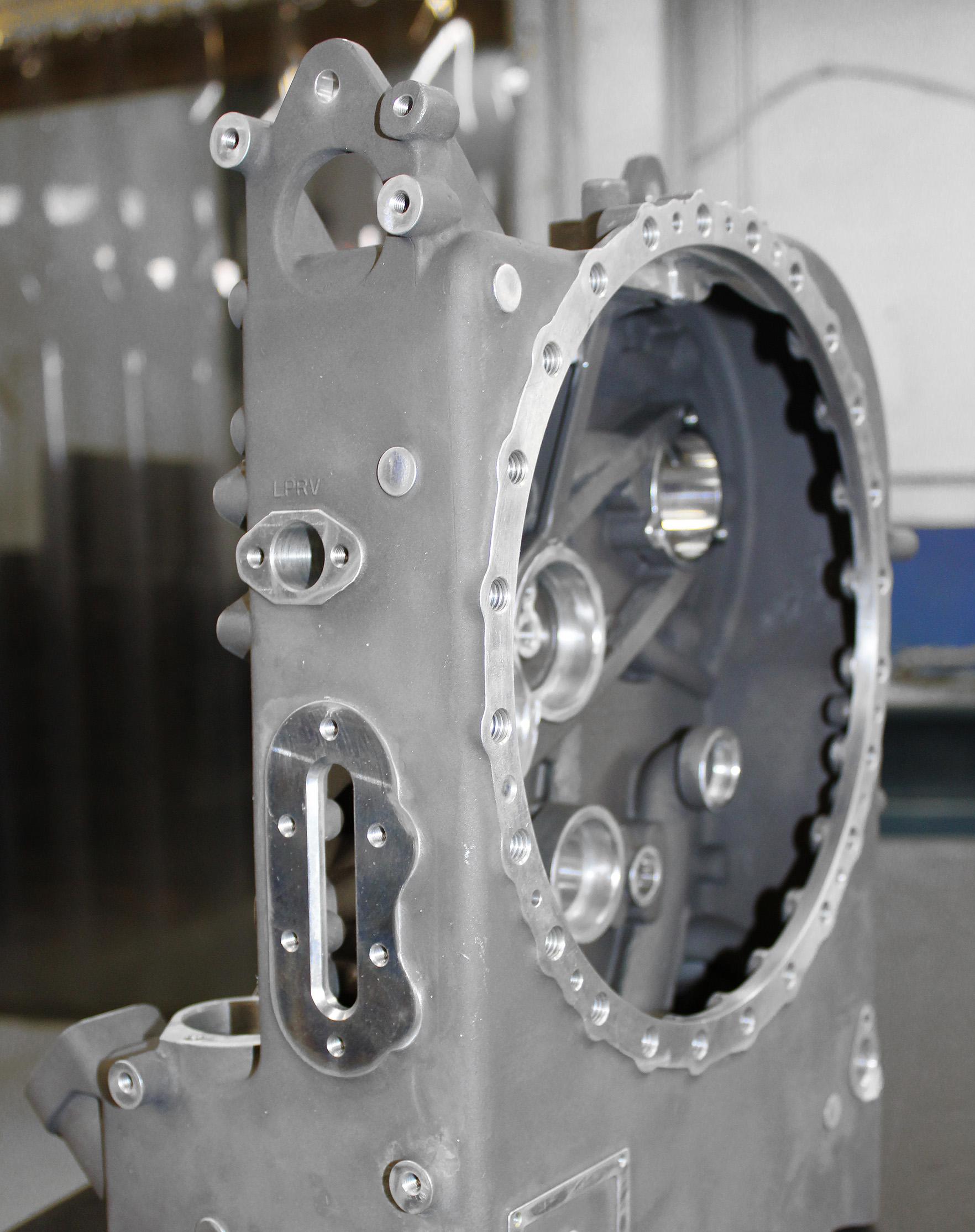

Precision Aluminum Components Engineered for Performance

Integra-Cast produces precision aluminum components designed to meet tight tolerances and demanding application requirements. Aluminum’s lightweight strength, corrosion resistance, and versatility make it an ideal material for aerospace, industrial, and high-performance applications. Our engineering-driven manufacturing processes ensure that every component delivers reliable structural integrity, dimensional accuracy, and long-term performance.

By maintaining strict process control and quality assurance throughout production, Integra-Cast provides components that are ready for direct assembly, reducing additional processing steps and improving overall manufacturing efficiency.

Advanced Aluminum Investment Casting Capabilities

Aluminum investment casting is a core strength at Integra-Cast, allowing us to produce complex geometries with excellent surface finish and near-net-shape accuracy. Through controlled tooling, alloy selection, and solidification processes, our precision investment casting capabilities support both low-volume and production-scale requirements.

This casting method enables the creation of intricate aluminum components while minimizing material waste and secondary machining. As a result, customers benefit from reduced costs, improved consistency, and faster production cycles without compromising quality.

Prototype Aluminum Casting for Rapid Development

Innovation begins with effective prototyping. Integra-Cast offers prototype aluminum casting services that help customers validate designs, test functionality, and accelerate product development. Prototype casting provides realistic material and performance characteristics, allowing engineers to identify improvements early in the design process.

Our aluminum prototyping services are designed to reduce development risk and shorten time to market. By integrating prototyping into our broader manufacturing workflow, we enable a smooth transition from prototype to full-scale production.

High-Precision Aluminum CNC Machining

Following casting or billet production, components often require finishing operations to achieve exact specifications. Integra-Cast delivers advanced aluminum CNC machining services using modern multi-axis equipment and precision tooling. These capabilities allow us to achieve tight tolerances, fine surface finishes, and complex features required for critical applications.

CNC machining also supports prototype refinement and low-volume production, giving customers the flexibility to make design adjustments while maintaining consistent quality across all manufacturing stages.

Integrated Services for Assembly-Ready Components

What sets Integra-Cast apart is our ability to combine casting, machining, and prototyping into a coordinated manufacturing solution. By managing precision investment casting, aluminum CNC machining, and aluminum prototyping services within a single production framework, we reduce supply chain complexity and enhance quality control.

This integrated approach delivers key advantages:

-

Shorter lead times from concept to finished component

-

Improved dimensional consistency and repeatability

-

Reduced rework and handling

-

Components delivered ready for assembly

Customers benefit from a streamlined manufacturing experience and predictable production outcomes.

Commitment to Quality and Reliability

Quality is embedded in every process at Integra-Cast. From initial design support to final inspection, each step is guided by documented procedures and rigorous verification methods. This ensures that every precision aluminum component meets customer specifications and industry standards.

Our focus on quality reduces risk, improves reliability, and supports long-term performance in demanding operating environments.

Your Partner for Precision Aluminum Manufacturing

As product designs become more complex and timelines more compressed, manufacturers require partners who can deliver both technical expertise and operational efficiency. Integra-Cast continues to invest in advanced equipment, skilled personnel, and process optimization to meet evolving customer needs.