Revolutionizing Manufacturing with Resistance Welding: Why Heron Welders Lead the Way

Discover how Heron Welders’ advanced resistance welders are transforming modern manufacturing with precision, efficiency, and reliability.

In today’s fast-paced industrial world, manufacturers face the challenge of meeting high production demands while maintaining exceptional quality. Welding, a cornerstone of modern manufacturing, plays a crucial role in industries ranging from automotive to aerospace, construction, and electronics. Among the many welding technologies available, resistance welding has emerged as one of the most efficient, cost-effective, and reliable solutions. At the forefront of this innovation is Heron Welders, a company dedicated to designing and delivering advanced resistance welders that empower businesses to achieve precision, productivity, and performance.

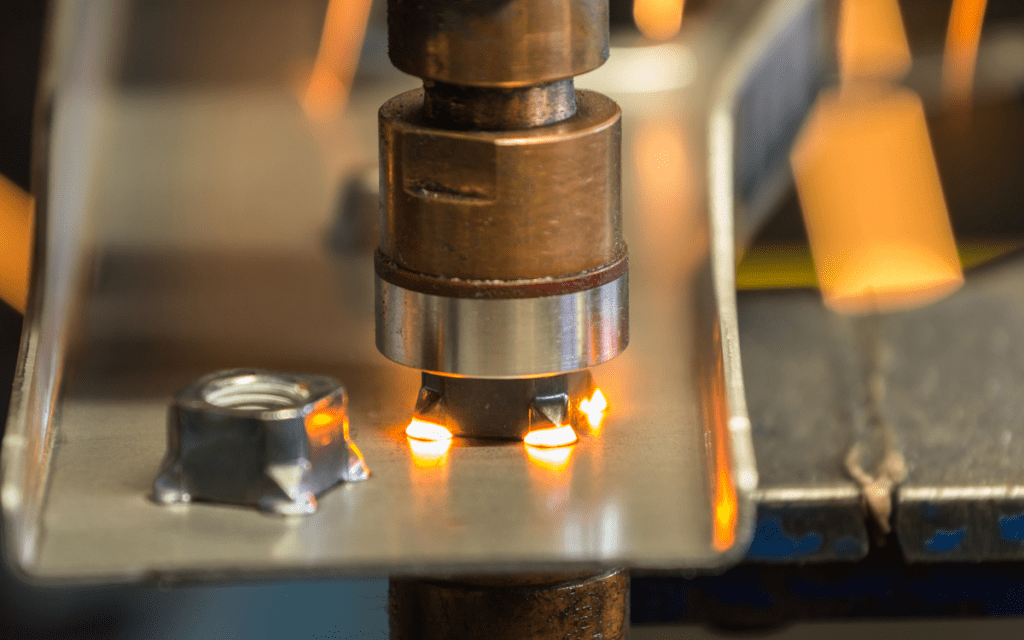

Resistance welding is a process where heat generated by electrical resistance is used to join two or more metal pieces together. Unlike traditional welding methods that rely on external filler materials or open flames, resistance welding provides a clean and efficient bond using controlled current and pressure. This makes it an ideal choice for industries that require durability, consistency, and speed.

Some key benefits of resistance welding include:

-

High Efficiency: The process requires no additional consumables, reducing material costs.

-

Speed: Welds can be completed in fractions of a second, making it ideal for mass production.

-

Strength & Reliability: Consistent quality ensures strong, lasting joints.

-

Eco-Friendly: Reduced emissions and no need for filler materials make it a greener option.

When it comes to industrial welding solutions, not all machines are created equal. Heron Welders have gained global recognition because of their commitment to precision engineering, cutting-edge technology, and customer-focused innovation. Here’s why manufacturers around the world trust Heron:

1. Advanced Technology for Unmatched Precision

Heron Welders utilize intelligent control systems that monitor and regulate current, pressure, and timing with exceptional accuracy. This ensures that every weld is consistent, reducing the risk of weak joints or defects. In industries such as automotive manufacturing—where a single weld can affect the safety of an entire vehicle—this level of precision is invaluable.

2. Efficiency That Drives Productivity

Modern manufacturing demands speed without compromising quality. Heron’s resistance welders are engineered to deliver rapid welding cycles, allowing companies to increase throughput and meet tight deadlines. The reduced downtime and consistent performance translate into significant cost savings.

3. Durability and Reliability in Every Machine

Industrial environments are demanding, and welding equipment must withstand continuous operation. Heron designs its welders with robust materials and components to ensure longevity. This durability means less maintenance, reduced downtime, and a greater return on investment.

4. Customization to Fit Industry Needs

Every industry has unique welding requirements, whether it’s spot welding in electronics, projection welding in automotive, or seam welding in metal fabrication. Heron Welders offer tailored solutions to meet specific demands. By working closely with clients, the company ensures that each machine delivers optimal performance for the intended application.

5. Commitment to Sustainability

Heron understands that sustainability is no longer optional—it’s essential. Resistance welding is inherently eco-friendly, and Heron enhances this benefit by designing energy-efficient machines that reduce waste and power consumption. Companies can improve their green credentials while maintaining high productivity.

The versatility of Heron’s resistance welders makes them invaluable across a wide range of industries. Let’s take a closer look at how different sectors benefit:

-

Automotive: Spot and projection welding are critical in automotive production, ensuring strong joints for car frames, fuel tanks, and exhaust systems. Heron Welders provide the strength and speed required in high-volume automotive plants.

-

Aerospace: In aerospace, precision and reliability are non-negotiable. Heron’s advanced control systems ensure every weld meets strict safety and quality standards.

-

Electronics: From small circuit boards to consumer electronics, resistance welding ensures delicate but durable connections without damaging sensitive components.

-

Construction: Welding is essential for building infrastructure, machinery, and heavy equipment. Heron’s durable welders deliver the strength needed for structural applications.

-

Energy: In renewable energy sectors, such as wind and solar, Heron’s welders help manufacturers produce components with long-lasting performance.

As industries evolve, the demand for smarter, faster, and greener solutions continues to grow. Heron Welders is already investing in advanced automation and digital integration to shape the future of resistance welding. Features like real-time data monitoring, predictive maintenance, and AI-assisted controls are paving the way for Industry 4.0-ready welding solutions.

By integrating these innovations, Heron not only helps businesses increase efficiency but also prepares them for the digital transformation of manufacturing. Companies that adopt Heron’s resistance welding technology today are positioning themselves for success in the highly competitive global market.

The answer is simple: Heron delivers excellence. From precision and durability to sustainability and innovation, Heron Welders are designed with the customer in mind. Choosing Heron means partnering with a trusted leader in the industry who is committed to pushing the boundaries of what welding technology can achieve.

Resistance welding is no longer just a manufacturing process—it’s a strategic advantage. Businesses that invest in advanced solutions can expect stronger products, higher efficiency, and lower costs. Heron Welders is leading this transformation by providing world-class resistance welders that combine technology, reliability, and sustainability.

Whether you’re in automotive, aerospace, construction, or electronics, Heron has the right solution to help you achieve your production goals. By choosing Heron, you’re not just purchasing a welding machine—you’re investing in the future of your business.