Buy Back Chamfer Tool for Accurate Hole Chamfering

Buy a chamfer tool for accurate hole chamfering and smooth internal edge finishing. Ideal for CNC machining, ensures precision, durability, and clean cuts.

Precision Back Chamfer Tool for Smooth Internal Hole Finishing

Manufacturers today are looking for very tight tolerances and the best edge quality possible for parts made in their supply chains. Many of these industries that require these tight tolerances are automotive, aerospace and heavy engineering. One solution that can help manufacturers of all types to achieve these requirements is to use back chamfering tools. Back chamfering tools are designed specifically to provide high-quality cutting results at an affordable cost per part when using burr removal and smooth hole finishing techniques.

What Is a Precision Back Chamfer Tool

Back chamfer tools are precision-engineered cutting instruments used for chamfering the rear edge of drilled holes. A back chamfer tool differs from normal chamfering tools, which work from the front, because it will either expand or cut from the back side of a hole after passing through it.

Back chamfer tools have been engineered to provide accurate chamfer angles at a consistent depth and produce a smooth surface finish. Back chamfer tools can be used on CNC machining centres, especially VMC machining centres, where accuracy and repeatability are of the utmost importance.

Importance of Smooth Internal Hole Finishing

It is essential to have smooth internal hole finishes when making parts that will be bolted together, pass fluids through them, or fit shafts into them. Rough or jagged/pointy edges on the inside of holes can lead to issues when assembling parts, cause stress fractures, and create dangerous conditions.

By using a precision back chamfer tool to produce burr-free finishes and getting an excellent edge break on the inside of the hole, you enhance the reliability of your products and reduce the time and cost of manual deburring during production.

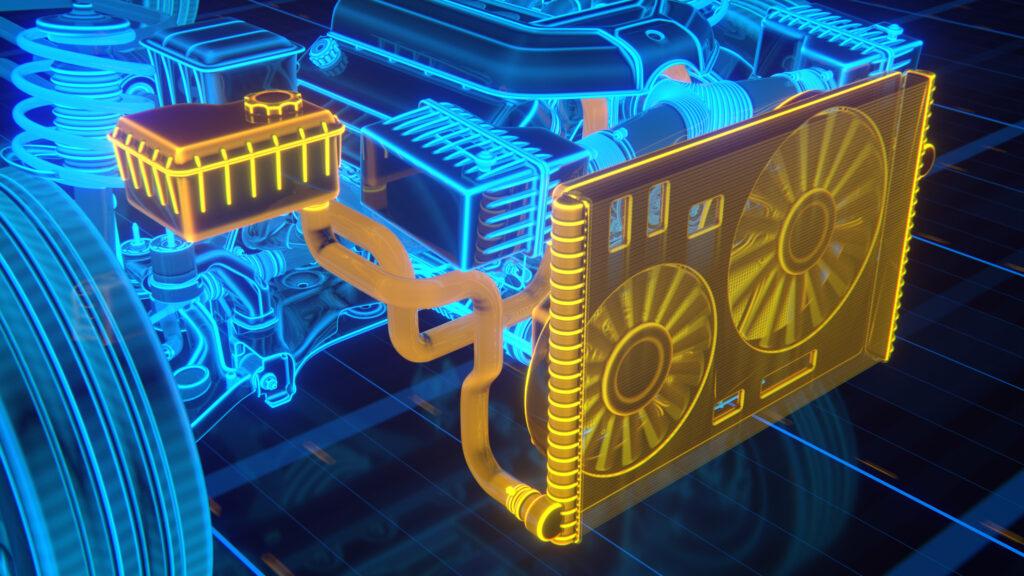

Applications ofthe Back Chamfer Tool for VMC

High-end vertical milling centres (VMCs) require back chamfer tools because of the need for precision during the manufacturing process. Moreover, the tools are required to perform evenly while rotating rapidly at high speeds and for producing large quantities of parts, components, or assemblies. Back chamfer tools are ideally suited for mass production as they provide precision, accuracy, repeatability, and the manufacture of parts quickly when used as machining tools. Back chamfer tooling is widely used by various industries when producing engine blocks, hydraulic valves and components, gear housings, and large steel structures, etc.

Understanding the 45-Degree Back Chamfer Tool

45 degree back chaffering tool is very popular in machine machining as stated above. 45 degree angle is often found as a standard dimension for the edging type of shape and for reinforcing edges based on drawings produced by engineers.

This angle allows maximum strength, minimises the concentration of stress and provides a good interface for assembling the parts. Precision-formed cutting edges produce uniform chamfers and a high-quality finish to both sides of parts produced from high-strength material.

Difference Between Front and Back Chamfer Tool

A dual front and back chamfering tool can chamfer the front and back of a hole. Front chamfering is straightforward; back chamfering requires extra design features to access the rear internal edge of the hole with a tool.

The combination tool improves production efficiency by reducing the number of tool changeovers and machining time. The combination tool is especially efficient for production operations that require a consistent finish to both edges in a single fixturing setup.

Key Features of a High-Quality Chamfer Tool for VMC

Chamfer Tools manufactured with premium carbide or high-speed steel create high-performance chamfer tools for CNC Machining Centre (VMC). They will create a high level of wear resistance, excellent thermal stability, and extended tool life.

The application of advanced coating technologies, such as TiN, TiCN, TiAlN, etc., on these tools will also create high levels of heat resistance and cutting efficiency. The precise balancing of the tool will provide vibration-free operation, producing a smooth finish on the internal holes of the part and increased tooling accuracy.

Benefits of Using Precision Back Chamfer Tools

When you use a high-precision backing chamfer tool, there are numerous benefits to you as a manufacturer. You will reduce the need for secondary manual operations, decrease time to produce parts, and have a more consistent chamfer size across multiple components.

You can also improve your assembly process by removing burrs or sharp edges. You can also improve the safety of your employees by eliminating possible injuries from sharp internal edges. As a manufacturer, you will be able to increase your overall productivity while lowering your overall operating costs.

Materials Suitable for Back Chamfering

The precision back chamfering tool is designed for use with numerous materials such as mild steel, alloy steel, stainless steel, aluminium, brass and cast iron.

If the cutting parameters are correct, the tool will continue to perform at a high level even on hardened materials. The correct tool is selected based on material type to obtain the best cutting results and longest tool life.

Tool Selection Criteria for Accurate Chamfering

Selecting the right back chamfer tool depends on hole diameter, required chamfer angle, material type, and machine capability. For CNC and VMC operations, stability and rigidity are crucial.

Choosing the correct 45-degree back chamfer tool or adjustable variant ensures consistent chamfer depth and surface finish. Proper tool holding systems further enhance machining accuracy and reduce runout.

Working Mechanism of Back Chamfer Tools

A back chamfer tool uses either a mechanical expansion or a pivoting mechanism to perform the cutting while simultaneously retracting from the hole. Once the tool is inside the hole, it expands or engages to chamfer (cut) the back edge of the workpiece and then retracts and/or disengages.

By means of this type of mechanism, the back chamfer tool ensures accuracy in chamfering while preventing damage to the front edge of the workpiece, as well as allowing for smooth entry and exit through the hole, and eliminating scratches and defects on the surface of the workpiece.

Role of CNC Technology in Back Chamfering

CNC machining has changed how chamfers are created because of its ability to program feeds/rate, spindle speed, and depth control. With these options available, CNC machinery delivers consistent and accurate chamfering.

Chamfer tooling for VMC's integration with CNC programming will eliminate human error while increasing productivity. It allows manufacturers to produce a consistent product, even though they use complex geometries and tight tolerances.

Maintenance and Care of Chamfer Tools

The lifespan of precision back chamfer tools can be extended through proper maintenance, regular inspection of the wear, chip or coating damage, all of which help to maximise tool life.

Ensuring tools are clean when being stored and using appropriate storage will assist in minimising corrosion and/or damage to tools. The use of recommended cutting parameters will also help to reduce excessive heat generation and wear on tools to help ensure a long-lasting tool life while maintaining the consistency of the internal hole finish produced by these tools.

Why Precision Matters in Industrial Applications

In certain industries, such as the automotive and aerospace industries, a small defect could create performance issues. The process of Precision Back Chamfering provides components with strict adherence to Quality Control as well as Engineering tolerances.

By ensuring that the Internal Finish of the component hole is smooth, this creates a reduction of stress points through even distribution of load on the component, creating structural integrity. The level of precision achieved will directly affect the reliability and longevity of the product.

About Jaibros

Jaibros is a reputable and reliable manufacturer of industrial tools. We offer a wide variety of high-quality cutting and machining tools that are specifically designed for today's advanced manufacturing technology of manufacturing. All of our precision-engineered cutting and machining tools exhibit precision, durability, and innovation — and we want to ensure our customers receive nothing but the best cutting and machining tools possible.

Our extensive collection of industrial tooling includes back chamfer tools for VMC machines, front and back chamfer tools for standard cut and saw applications, as well as speciality 45-degree back chamfer tooling, all engineered for superior accuracy and durability. Jaibros uses both technical expertise and in-depth industry knowledge to assist manufacturers who will become high-volume manufacturers through improved machining quality and speed.

Conclusion

The precision of back chamfering tools is essential to perfect the finish of an internal hole and consistently achieve the highest possible level of machining quality. They increase the fit of your assembly during installation, eliminate burrs and sharp edges on the products you process, and improve the safety and performance of your machined parts. No matter if you are using a back chamfering tool on a VMC machine, a front and back chamfering tool, or a 45-degree back chamfering tool, you will achieve a reliable performance as long as you use the correct tools to achieve continued accuracy for as long as you need.

Mechanical precision and production efficiency are imperative in manufacturing today. For this reason, it is critical to invest in top-quality chamfering tools, which increase production rates, reduce rework from non-conforming parts and lower production costs. With the assistance of Jaibros with their wide variety of chamfering tools, manufacturers have the tools needed to achieve superior finishing and meet the stringent requirements of the industry.