Laser Galvo Innovation for Precision Manufacturing: How LaserChina is Redefining Industrial Speed and Accuracy

The Power of Motion in Modern Laser Technology

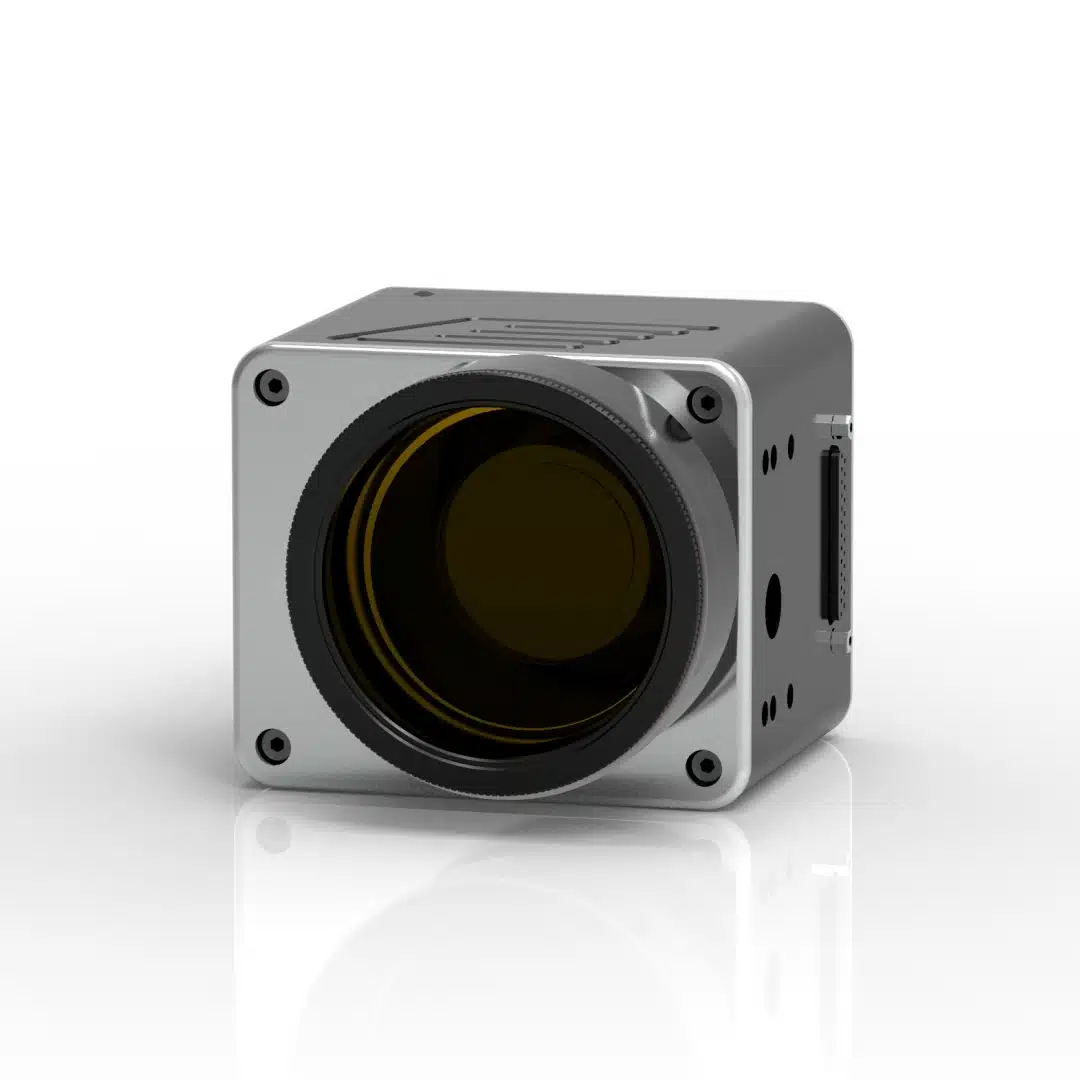

In the evolving world of industrial laser systems, speed and precision define success. The laser galvo a critical component that directs and positions laser beams with remarkable accuracy has become the heart of next-generation laser marking, engraving, and cutting systems. For manufacturers, workshops, and OEMs seeking faster production with uncompromised detail, LaserChina stands as a trusted partner offering cutting-edge galvo solutions designed to meet today’s market challenges.

LaserChina’s laser galvo systems are not just components; they are the precision engines that enable productivity, efficiency, and scalability across industries such as automotive, electronics, medical devices, and metal fabrication.

Understanding Laser Galvo Technology

At its core, a laser galvo system uses high-speed galvanometer mirrors to steer laser beams with exceptional agility. Controlled by advanced servo systems, these mirrors rapidly adjust angles, enabling intricate and fast laser marking, cutting, or welding over large working fields.

Key Functional Insights:

-

Mirror Dynamics: High-reflectivity mirrors paired with lightweight materials allow for ultra-fast oscillation with minimal inertia.

-

Positioning Accuracy: Integrated feedback sensors ensure sub-micron precision, vital for applications demanding tight tolerances.

-

Thermal Stability: Optimized designs prevent mirror distortion under high laser power, ensuring consistency during long production cycles.

This combination of speed and accuracy makes galvo systems indispensable in any high-throughput manufacturing setup.

Market Demand: Why Industries Are Turning to Galvo-Based Laser Systems

The global manufacturing sector is witnessing an accelerating shift toward automation and precision-driven processes. Markets demand compact, cost-efficient, and high-speed marking or cutting systems that minimize downtime while maintaining superior quality.

Current Industrial Trends:

-

High-Speed Marking for Traceability: With the growing need for product identification and compliance, laser galvo systems allow permanent, high-resolution marking without slowing production lines.

-

Smart Manufacturing Integration: Compatibility with CNC and robotic systems enables synchronized motion control for continuous operation.

-

Miniaturization of Components: Electronics and medical sectors increasingly rely on micro-marking capabilities achievable only through high-speed galvo control.

LaserChina recognizes these industrial pressures and has developed its laser galvo range to match the pace of modern factories—delivering consistency at industrial scale.

LaserChina’s Edge: Precision Engineering Meets Industrial Reliability

As one of China’s leading laser solution providers, LaserChina brings decades of experience in laser technology innovation. Their laser galvo systems embody a balance of speed, accuracy, and endurance tailored for B2B clients.

Core Features That Define LaserChina’s Galvo Series:

-

High-Speed Scanning: Up to several thousand mm/s, optimizing laser throughput for mass production.

-

Compact Design: Ideal for integration into fiber, CO₂, or UV laser systems.

-

Durability: Designed for continuous industrial operation with low maintenance requirements.

-

Flexible Control Options: Compatible with major laser control software, supporting diverse manufacturing workflows.

-

Custom Solutions: Adaptable designs for OEM partnerships and custom automation setups.

By engineering solutions for real-world industrial challenges, LaserChina enables manufacturers to achieve more with less—reducing costs while enhancing operational efficiency.

Meeting Global Market Standards

Global competition has raised the bar for manufacturing excellence. Whether it’s ISO certification compliance, international safety standards, or energy-efficient production, companies now expect laser components to perform flawlessly within integrated systems.

LaserChina’s Quality Philosophy:

-

Precision Manufacturing: Every galvo mirror and driver undergoes rigorous calibration and testing.

-

Material Selection: Only premium optical glass and aerospace-grade alloys are used for structural stability.

-

Performance Validation: Each unit is tested under simulated industrial stress to ensure reliable performance under extreme conditions.

-

Energy Efficiency: Advanced motor control algorithms reduce power consumption without compromising scanning speed.

These attributes make LaserChina’s galvo systems the preferred choice for industries demanding high-speed laser marking with lasting reliability.

Applications Across Industries

LaserChina’s laser galvo solutions have become integral in multiple sectors, where precision and speed translate directly into profitability.

Key Application Areas:

-

Electronics Manufacturing: PCB etching, chip marking, and micro engraving.

-

Automotive Production: Component identification, VIN marking, and decorative surface treatments.

-

Medical Devices: Fine text engraving on surgical instruments and implantable components.

-

Packaging & Consumer Goods: High-speed code marking on plastics, glass, and metals.

-

Textile & Leather Processing: Precision engraving and pattern creation for custom designs.

Every application benefits from reduced cycle time, minimal maintenance, and perfect consistency—a testament to LaserChina’s engineering quality.

Innovation Pipeline: What’s Next for LaserChina

Staying ahead of industry trends, LaserChina continually invests in research and development to push galvo technology boundaries.

Emerging Developments Include:

-

AI-Driven Beam Path Optimization: Intelligent algorithms for smoother scanning and reduced edge distortion.

-

Enhanced Cooling Systems: Next-gen thermal control to support high-power lasers for extended durations.

-

Integrated Smart Feedback: Real-time monitoring for predictive maintenance and system longevity.

-

Multi-Head Synchronization: Coordinated galvo systems for large-scale industrial engraving or cutting.

Such forward-looking innovation ensures LaserChina remains synonymous with reliability, performance, and industrial advancement.

Why Businesses Choose LaserChina

B2B buyers prioritize dependability, ROI, and service support. LaserChina’s comprehensive product ecosystem, technical consultation, and after-sales support make it an ideal partner for enterprises aiming to upgrade their laser systems.

Business Advantages:

-

End-to-end customization for OEMs and integrators.

-

Competitive global pricing without compromising performance.

-

Local and international service networks for technical assurance.

-

Proven success across hundreds of industrial installations worldwide.

With LaserChina, businesses don’t just purchase a laser galvo—they invest in a long-term performance solution built for industrial growth.

Conclusion: Precision, Power, and Partnership

As industries evolve toward smarter and faster production, LaserChina’s laser galvo technology sets a new benchmark for accuracy and speed in laser-based manufacturing. By blending innovation with practical reliability, LaserChina empowers industrial partners to achieve peak productivity while meeting global standards.

For manufacturers seeking high-speed precision and long-term reliability, LaserChina remains the go-to expert in laser galvo solutions—where every movement counts, and every result defines excellence.