Why Are Yuanda Air Showers Trusted by Pharma Facilities

In modern controlled environments, the Air Shower provided by yd-purification serves as an essential solution to safeguard operational integrity, prevent contamination, and ensure that personnel and materials entering sensitive areas comply with stringent hygiene standards. The importance of such systems extends across multiple industries including pharmaceuticals, biotechnology, electronics manufacturing, medical device production, and precision laboratories, where maintaining sterile and controlled conditions is not optional but a fundamental requirement.

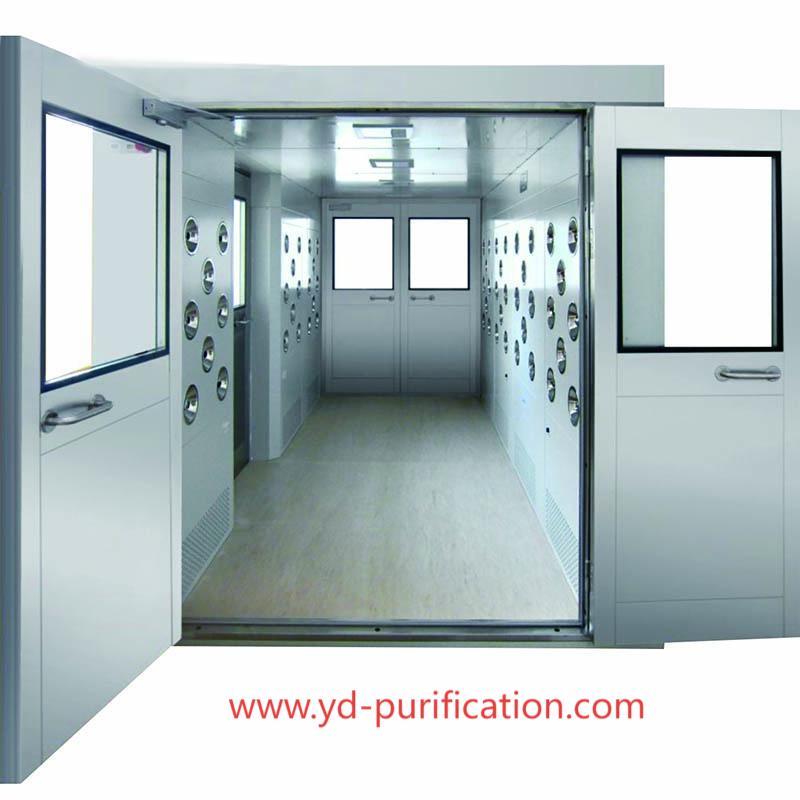

These air showers are engineered with high-efficiency particulate filters, carefully designed airflow patterns, and robust construction, delivering effective removal of dust, particles, and microscopic debris from clothing, footwear, and equipment. By generating a controlled, high-velocity air curtain, contaminants are dislodged and captured within the filtration system before personnel enter critical zones. The controlled passage ensures minimal disruption to workflow while upholding the strict environmental standards required for operational compliance.

Beyond functionality, attention to design, safety, and ergonomics ensures both user comfort and operational clarity. Smooth surfaces, fully sealed doors, strategically placed nozzles, and high-quality materials create a professional environment that supports effective cleaning while providing a visually organized and disciplined workspace. Observation panels or transparent doors allow supervisors to monitor personnel compliance without compromising environmental separation, reinforcing trust in facility protocols and operational rigor.

Safety mechanisms are embedded throughout the system, including sensor-based interlocks, automated door operations, and emergency stop functions, which provide reliable protection for personnel while maintaining the integrity of controlled areas. Even under high traffic, the system continues to operate reliably, preventing cross-contamination and ensuring that environmental conditions remain consistent with regulatory requirements.

Operational efficiency is further enhanced through energy-conscious design and low-maintenance components. Durable materials, high-performance fans, and optimized airflow not only reduce energy consumption but also minimize the need for frequent maintenance, extending the lifespan of the system while maintaining its high performance. Integration with facility monitoring systems allows real-time tracking of environmental conditions and compliance, enabling managers to oversee operations effectively and make informed adjustments where necessary.

For industries where contamination control, personnel safety, and operational efficiency converge, these advanced air showers represent a crucial investment. Organizations looking for reliable, precise, and sustainable solutions can explore the offerings by visiting www.yd-purification.com , where innovative Air Shower systems are designed for demanding cleanrooms, laboratories, and controlled production environments.