Cbbmachine Banana Rollers Integration in Automated Web Processing Lines

In modern web handling and roll-to-roll production systems, Banana Rollers play a crucial role in maintaining proper tension, alignment, and material stability during winding and unwinding operations. These uniquely shaped components are engineered to handle flexible materials such as films, foils, paper, or textiles while preventing edge damage and ensuring consistent roll formation. Their curved design distributes pressure evenly across the material, reducing the risk of wrinkling, telescoping, or misalignment in high-speed production processes.

The primary advantage of these specialized rollers lies in their ability to correct lateral tracking issues. In many industrial applications, materials tend to drift along the edges of the roll, causing uneven winding and production defects. By applying subtle curvature and controlled pressure, the air-assisted guiding rollers gently steer the web toward the center of the roll, preserving the material's integrity while improving operational efficiency and reducing waste.

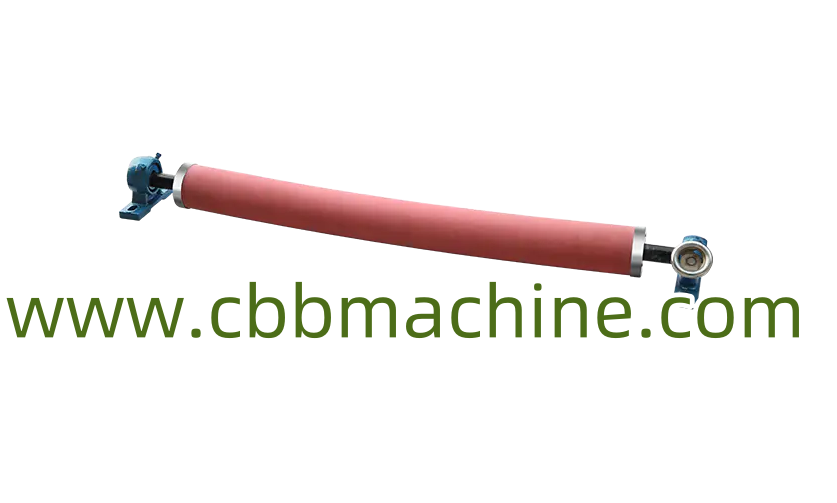

Durability is a key consideration for these components. They are often constructed from hardened steel, aluminum, or coated surfaces designed to withstand continuous operation and resist wear. Proper alignment and installation are critical, as even minor deviations can compromise the system's effectiveness. Advanced designs may include adjustable angles or modular mounts, allowing operators to fine-tune the system based on material width, thickness, and production speed.

Beyond traditional winding applications, these curved rollers are increasingly utilized in processes such as coating, laminating, and printing. They assist in maintaining consistent tension and prevent edge curling, ensuring high-quality output. When integrated with tension controllers and automated systems, they become part of a fully coordinated production line capable of reducing manual intervention while optimizing throughput.

Safety and maintenance are also essential. Secure installation prevents accidental slippage or material damage, protecting both operators and machinery. Routine inspections, lubrication, and alignment checks ensure smooth operation and extend the lifespan of the rollers, helping facilities maintain consistent production schedules and minimize downtime.

Technological advancements have enhanced their performance further. Modern systems incorporate specialized coatings and surface finishes to reduce friction and wear, while modular mounting enables quick adjustments for different production requirements. In more advanced setups, sensors can monitor material behavior and provide real-time feedback, aligning with trends in smart manufacturing and digital process control.

Selecting the appropriate roller setup requires careful consideration of material properties, line speed, and production goals. Collaborating with a reputable supplier ensures that each system meets operational requirements, offers long-term reliability, and integrates seamlessly with existing machinery. By implementing these systems, manufacturers achieve consistent roll quality, improved process efficiency, and reduced material waste.

Overall, curved guiding rollers exemplify how innovative mechanical design can solve common web-handling challenges while enhancing productivity, safety, and product quality in industrial operations.