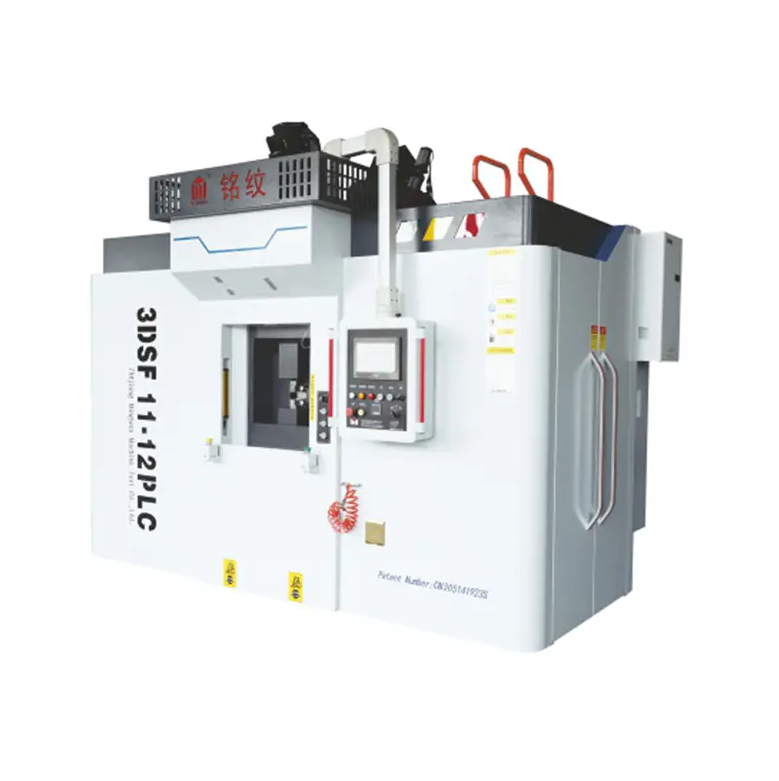

Maximize Your Brass Fitting Output: How Rotary Transfer Machines Slash Cycle Times

In the competitive world of brass fitting manufacturing, efficiency, precision, and cost-effectiveness are not just goals—they are necessities. If your company is relying on multiple standalone machines for drilling, tapping, milling, and threading, you are likely facing significant bottlenecks, high labor costs, and inconsistent quality. It's time to consider a transformative solution: the Rotary Transfer Machine for Brass Fitting.

Our Rotary Transfer Machine is engineered specifically for high-volume production of complex brass components. Imagine a single, integrated system where a raw brass workpiece is loaded and emerges as a finished, precision-machined fitting, all in one continuous cycle. This is the essence of rotary transfer technology. The component is indexed through a circular series of workstations, each performing a dedicated operation simultaneously. While one station is drilling, another is tapping, and a third is performing quality checks.

The immediate benefit is a dramatic increase in output. By eliminating the need to transport parts between different machines, we minimize non-value-added time. Cycle times are slashed, and parts-per-hour rates soar. Furthermore, with automation at its core, the machine drastically reduces direct labor requirements, allowing your skilled operators to focus on supervision and quality control rather than manual loading and unloading. For any brass fitting manufacturer aiming to scale operations and dominate the market, the Rotary Transfer Machine is the most strategic investment you can make.