The Role of Automation in Color Coating

Color coating is an essential manufacturing process that enhances the aesthetic appeal and durability of metal products, particularly in industries like construction, color coating line automotive, and consumer goods. The color coating line is a sophisticated system designed to apply a decorative and protective layer of paint to metal substrates, ensuring a uniform finish while optimizing efficiency.

The Color Coating Process

The color coating process begins with the preparation of the metal substrate, typically made of steel or aluminum. This step is critical for ensuring the coating adheres properly to the surface. The cleaning process removes contaminants such as oils, dust, and rust, often using alkaline solutions or acid washes. After cleaning, a surface treatment, such as a primer or conversion coating, may be applied to improve adhesion and enhance corrosion resistance.

Once the substrate is prepared, the actual color coating begins. The most common method used in color coating is spray application, where paint is atomized and evenly sprayed onto the surface of the metal. However, other methods such as roll coating or dip coating can also be employed, depending on the specific requirements of the product and the desired finish. The choice of application method affects the thickness, texture, and overall appearance of the final coating.

After the color has been applied, the coated metal moves through a curing oven. Curing is a vital step that involves heating the coated metal to a specific temperature for a set duration. This process hardens the coating, enhancing its chemical and physical properties, and ensuring that it can withstand environmental stressors such as UV rays, moisture, and temperature fluctuations.

Advantages of Color Coating

Color coating offers several significant advantages. One of the primary benefits is the aesthetic enhancement it provides. Manufacturers can achieve a wide range of colors and finishes, allowing them to cater to diverse design preferences. This versatility is particularly valuable in industries like architecture and automotive design, where visual appeal is critical.

In addition to aesthetics, color coating provides substantial protective benefits. The coatings act as a barrier against corrosion, UV damage, and physical wear, extending the lifespan of metal products and reducing maintenance costs. This protective layer is especially advantageous for outdoor applications, where materials face constant exposure to the elements.

Efficiency is another key advantage of color coating lines. The continuous nature of the color coating process allows for high production rates, significantly reducing labor costs and time compared to traditional painting methods. Automated systems ensure consistent application, minimizing variations in thickness and appearance, which is essential for maintaining product quality.

Applications of Color Coated Products

Color-coated metals are widely utilized across various industries. In construction, they are commonly used for roofing, siding, and interior wall panels. In the automotive sector, color-coated materials find applications in body panels and trim. Additionally, consumer goods like appliances and furniture often feature color-coated finishes for added protection and aesthetic appeal.

Conclusion

In conclusion, color coating lines represent a vital aspect of modern manufacturing processes. By providing efficient, high-quality, and visually appealing coatings for metal products, these lines significantly contribute to various industries. As technology continues to advance, the color coating process is likely to evolve, leading to innovative solutions that meet the demands of manufacturers and consumers alike. The ongoing development in this field promises to enhance the efficiency and sustainability of metal product manufacturing, solidifying the importance of color coating in the industrial landscape.

Categories

Read More

Micro Nasdaq futures have become increasingly popular among traders who want to engage in futures markets with smaller contract sizes. These contracts allow traders to gain exposure to the Nasdaq index while managing risk more effectively. Understanding how the best futures trading platforms support micro Nasdaq futures trading is essential for both beginner and experienced traders who want to...

Market Definition E-Passport and E-Visa Market refers to digital identity and travel authorization systems that use embedded electronic chips, biometric authentication, and secure databases to enhance border security, streamline immigration processes, and reduce fraud. E-passports store encrypted personal and biometric data such as fingerprints and facial images, while e-visa...

Introduction to Taxi Services in Gateshead Gateshead, a vibrant town in the northeast of England, is known for its historic sites, thriving cultural scene, and bustling business districts. Whether you are a resident or a visitor, reliable transportation is essential to navigate the town efficiently. Taxi in Gateshead offer a convenient solution for commuting, ensuring you reach your destination...

Wheat Protein Isolates Market Summary “The global Wheat Protein Isolates Market is expected to reach to USD 1337.6 million by 2032, growing at a CAGR of 11.5% during 2025 to 2032” The TrendBridge Insights Research report, “Global Wheat Protein Isolates Market Report 2025 – Future Opportunities, Latest Trends, In-depth Analysis, and Forecast To 2032”,...

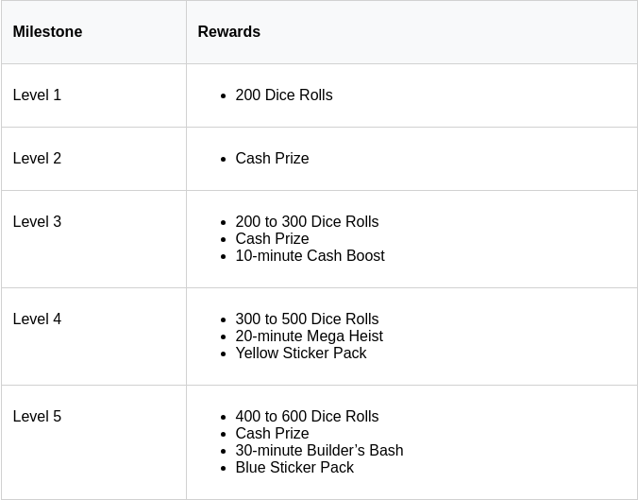

The latest collectible added to Monopoly GO’s expanding Star Wars lineup is the formidable Darth Maul token. Crafted with intricate detail, this token captures Darth Maul’s menacing aura, showcasing his signature double-bladed lightsaber and fierce red-and-black design. If you’ve already gathered all the previous Star Wars-themed cosmetics, acquiring this item will...