The Role of Automation in Color Coating

Color coating is an essential manufacturing process that enhances the aesthetic appeal and durability of metal products, particularly in industries like construction, color coating line automotive, and consumer goods. The color coating line is a sophisticated system designed to apply a decorative and protective layer of paint to metal substrates, ensuring a uniform finish while optimizing efficiency.

The Color Coating Process

The color coating process begins with the preparation of the metal substrate, typically made of steel or aluminum. This step is critical for ensuring the coating adheres properly to the surface. The cleaning process removes contaminants such as oils, dust, and rust, often using alkaline solutions or acid washes. After cleaning, a surface treatment, such as a primer or conversion coating, may be applied to improve adhesion and enhance corrosion resistance.

Once the substrate is prepared, the actual color coating begins. The most common method used in color coating is spray application, where paint is atomized and evenly sprayed onto the surface of the metal. However, other methods such as roll coating or dip coating can also be employed, depending on the specific requirements of the product and the desired finish. The choice of application method affects the thickness, texture, and overall appearance of the final coating.

After the color has been applied, the coated metal moves through a curing oven. Curing is a vital step that involves heating the coated metal to a specific temperature for a set duration. This process hardens the coating, enhancing its chemical and physical properties, and ensuring that it can withstand environmental stressors such as UV rays, moisture, and temperature fluctuations.

Advantages of Color Coating

Color coating offers several significant advantages. One of the primary benefits is the aesthetic enhancement it provides. Manufacturers can achieve a wide range of colors and finishes, allowing them to cater to diverse design preferences. This versatility is particularly valuable in industries like architecture and automotive design, where visual appeal is critical.

In addition to aesthetics, color coating provides substantial protective benefits. The coatings act as a barrier against corrosion, UV damage, and physical wear, extending the lifespan of metal products and reducing maintenance costs. This protective layer is especially advantageous for outdoor applications, where materials face constant exposure to the elements.

Efficiency is another key advantage of color coating lines. The continuous nature of the color coating process allows for high production rates, significantly reducing labor costs and time compared to traditional painting methods. Automated systems ensure consistent application, minimizing variations in thickness and appearance, which is essential for maintaining product quality.

Applications of Color Coated Products

Color-coated metals are widely utilized across various industries. In construction, they are commonly used for roofing, siding, and interior wall panels. In the automotive sector, color-coated materials find applications in body panels and trim. Additionally, consumer goods like appliances and furniture often feature color-coated finishes for added protection and aesthetic appeal.

Conclusion

In conclusion, color coating lines represent a vital aspect of modern manufacturing processes. By providing efficient, high-quality, and visually appealing coatings for metal products, these lines significantly contribute to various industries. As technology continues to advance, the color coating process is likely to evolve, leading to innovative solutions that meet the demands of manufacturers and consumers alike. The ongoing development in this field promises to enhance the efficiency and sustainability of metal product manufacturing, solidifying the importance of color coating in the industrial landscape.

Kategoriler

Read More

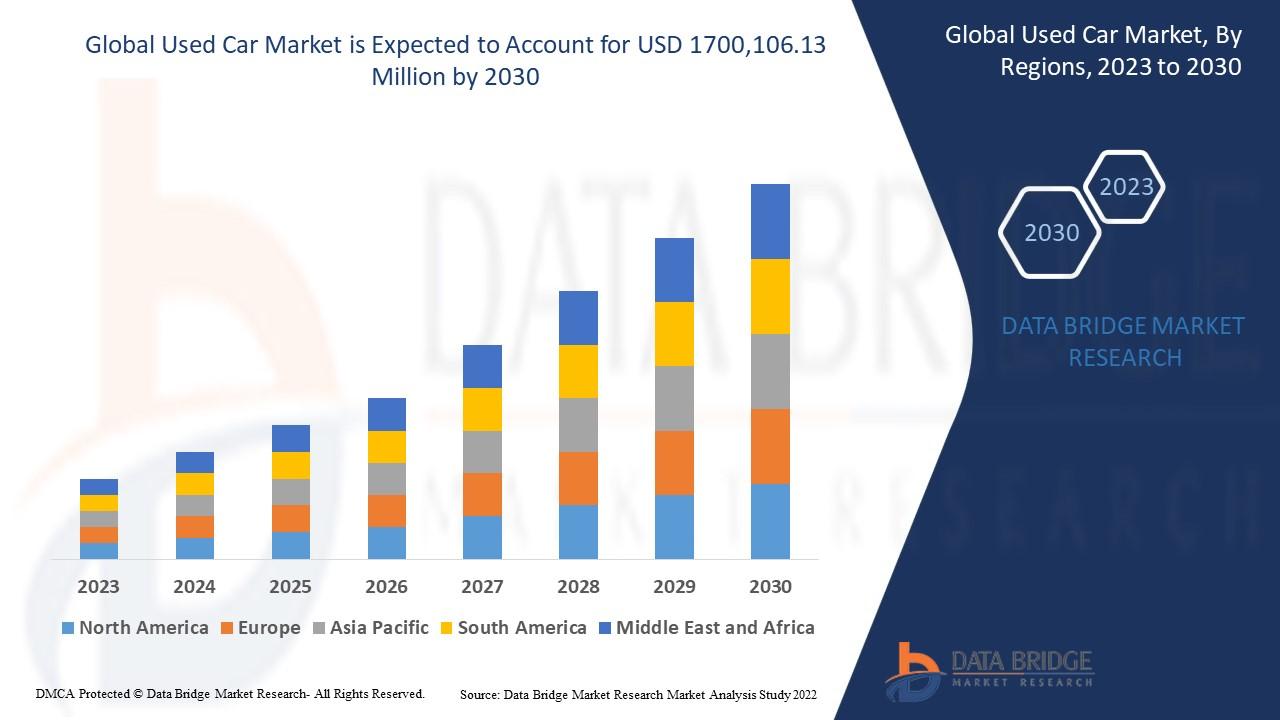

"Executive Summary Used Car Market: Growth Trends and Share Breakdown CAGR Value Data Bridge Market Research analyses that the global used car market was valued at USD 996,906.42 million in 2022 and is expected to reach the value of USD 1700,106.13 million by 2030, at a CAGR of 6.90% during the forecast period. The Used Car Market report has been formed with the appropriate...

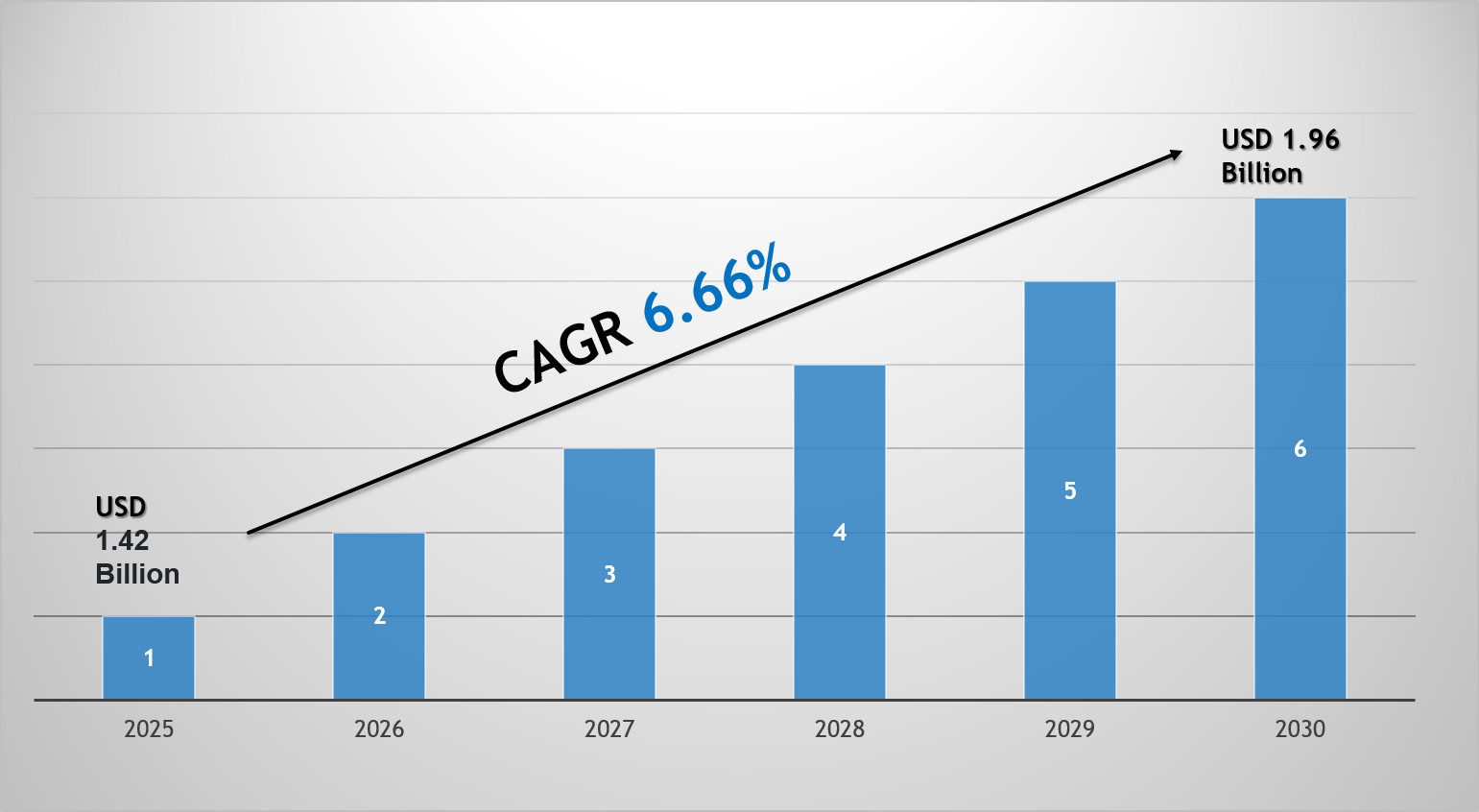

Future Medical Oxygen Concentrator Market: Key Dynamics, Size & Share Analysis The Global Medical Oxygen Concentrator Market size is valued at around USD 1.42 billion in 2025 and is projected to reach USD 1.96 billion by 2030. Along with this, the market is estimated to grow at a CAGR of around 6.66% during the forecast period, i.e., 2025-30. The market growth is primarily driven...

In an age of autonomous mobility and intelligent transportation, automotive platooning systems are reshaping commercial logistics by enabling convoys of connected vehicles to travel in tight formation—slashing fuel costs, emissions, and driver fatigue while boosting road capacity. The global automotive platooning system market size was valued at USD 1.70 billion in...

Executive Summary: Pore Strips Market Size and Share by Application & Industry Data Bridge Market Research analyses that the global pore strips market will project a CAGR of 5.30% for the forecast period of 2022-2029. For the growth of business, Pore Strips analysis report has a lot to offer and hence it plays a very important role in growth. Myriad of factors have been studied in...

Traveling from Rajkot to Sasan Gir is more than just a road journey—it’s the gateway to an unforgettable wildlife experience at Gir National Park, the only home of Asiatic lions. Choosing a Rajkot to Sasan Gir Taxi Service ensures a comfortable, safe, and hassle-free trip, especially for families, wildlife enthusiasts, and tourists visiting Gujarat. With scenic highways,...