How Dry Ice Blasting Provides a Faster and Cleaner Solution for Industrial Maintenance

How Dry Ice Blasting Provides a Faster and Cleaner Solution for Industrial Maintenance

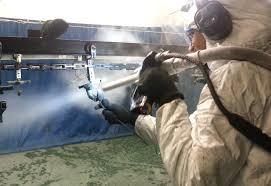

Dry Ice Blasting is an advanced cleaning technology that is transforming industrial maintenance. Unlike traditional methods that rely on water, chemicals, or abrasive materials, dry ice blasting uses solid CO₂ pellets accelerated at high speed. Upon impact, these pellets sublimate—turning from solid to gas—removing grease, paint, oil, and other contaminants without leaving residue or moisture. This method is safe, efficient, and environmentally friendly, making it ideal for delicate machinery and high-value equipment.

How Dry Ice Blasting Works

Dry ice blasting cleans surfaces through a combination of three effects:

-

Impact: High-speed pellets strike contaminants, breaking them free from the surface.

-

Thermal Shock: Extreme cold causes grime and residues to contract, loosening adhesion.

-

Sublimation: The dry ice vaporizes instantly, expanding and lifting debris without creating secondary waste.

This process ensures a deep, effective clean while preserving the integrity of sensitive equipment.

Benefits of Dry Ice Blasting

-

Non-Abrasive: Safe for metals, plastics, electronics, and coatings.

-

Residue-Free: No water, sand, or chemical residue is left behind.

-

Chemical-Free: Reduces exposure to hazardous cleaning agents.

-

Reduced Downtime: Equipment can often be cleaned in place without disassembly.

-

Eco-Friendly: Uses recycled CO₂ and minimizes environmental impact.

Applications in Various Industries

Manufacturing

Removes grease, oils, adhesives, and residues from molds, presses, and conveyor systems while production continues.

Food and Beverage

Sanitizes processing lines safely and efficiently, maintaining compliance with FDA and USDA standards.

Automotive and Aerospace

Cleans engines, molds, tools, and components without harming surfaces or precision parts.

Electrical and Power Systems

Non-conductive dry ice allows safe cleaning of transformers, turbines, and control panels.

Environmental and Workplace Advantages

Dry ice blasting eliminates chemical waste, reduces water usage, and minimizes operator exposure to hazardous substances. Its residue-free, dry cleaning process also prevents corrosion and extends the lifespan of equipment, lowering maintenance costs and improving overall operational efficiency.

Conclusion

Dry ice blasting is a modern, efficient, and environmentally responsible cleaning solution. Its non-abrasive, chemical-free, and residue-free process ensures industrial equipment stays clean, safe, and operational.

For professional and reliable dry ice blasting services, trust Top Dry Ice — your expert partner for eco-friendly, high-performance industrial cleaning solutions.

Κατηγορίες

Διαβάζω περισσότερα

Executive Summary North America Laryngoscopes Market : Data Bridge Market Research analyses that the North America laryngoscopes market to be growing at CAGR of 10.9% in the forecast period of 2021-2028. As it is important to have valuable and actionable market insights for creating sustainable and profitable business strategies. This North America Laryngoscopes Market research report...

Benefits of Using Certification Exam Preparation Material Certification exams help people grow in their careers. They help you get better jobs. They also help you earn more money. Many students want to pass the ACP-01101 exam on the first attempt. This exam is offered by Autodesk. However, exam preparation can feel difficult. There are many books to read and many topics to cover. This is why...

Explore a Recognized OTHM Diploma in Pakistan with IEHSAS If you're looking to elevate your professional qualifications and gain international recognition, the OTHM Diploma in Pakistan is one of the most valuable credentials you can pursue. Through IEHSAS, a trusted name in professional training and international certifications, you can now access accredited OTHM courses tailored to meet...

In today’s fast-paced digital world, online gaming and sports betting have become one of the most exciting forms of entertainment. Millions of players across the globe log in every day to enjoy the thrill of live sports betting, casino games, and fantasy leagues. At the center of this revolution is Fairplay Global, a platform that has quickly earned the trust of users by combining...

Advancements in Monitoring and Tracking Through Smart Fish Tagging Solutions The intersection of marine biology and advanced technology has ushered in an era of unprecedented capability in aquatic research. Fish tagging has evolved far beyond simple identification markers, transforming into sophisticated monitoring platforms that provide multidimensional insights into fish behavior, physiology,...