How Dry Ice Blasting Provides a Faster and Cleaner Solution for Industrial Maintenance

How Dry Ice Blasting Provides a Faster and Cleaner Solution for Industrial Maintenance

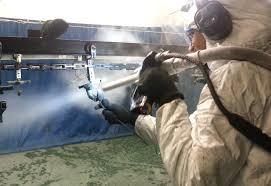

Dry Ice Blasting is an advanced cleaning technology that is transforming industrial maintenance. Unlike traditional methods that rely on water, chemicals, or abrasive materials, dry ice blasting uses solid CO₂ pellets accelerated at high speed. Upon impact, these pellets sublimate—turning from solid to gas—removing grease, paint, oil, and other contaminants without leaving residue or moisture. This method is safe, efficient, and environmentally friendly, making it ideal for delicate machinery and high-value equipment.

How Dry Ice Blasting Works

Dry ice blasting cleans surfaces through a combination of three effects:

-

Impact: High-speed pellets strike contaminants, breaking them free from the surface.

-

Thermal Shock: Extreme cold causes grime and residues to contract, loosening adhesion.

-

Sublimation: The dry ice vaporizes instantly, expanding and lifting debris without creating secondary waste.

This process ensures a deep, effective clean while preserving the integrity of sensitive equipment.

Benefits of Dry Ice Blasting

-

Non-Abrasive: Safe for metals, plastics, electronics, and coatings.

-

Residue-Free: No water, sand, or chemical residue is left behind.

-

Chemical-Free: Reduces exposure to hazardous cleaning agents.

-

Reduced Downtime: Equipment can often be cleaned in place without disassembly.

-

Eco-Friendly: Uses recycled CO₂ and minimizes environmental impact.

Applications in Various Industries

Manufacturing

Removes grease, oils, adhesives, and residues from molds, presses, and conveyor systems while production continues.

Food and Beverage

Sanitizes processing lines safely and efficiently, maintaining compliance with FDA and USDA standards.

Automotive and Aerospace

Cleans engines, molds, tools, and components without harming surfaces or precision parts.

Electrical and Power Systems

Non-conductive dry ice allows safe cleaning of transformers, turbines, and control panels.

Environmental and Workplace Advantages

Dry ice blasting eliminates chemical waste, reduces water usage, and minimizes operator exposure to hazardous substances. Its residue-free, dry cleaning process also prevents corrosion and extends the lifespan of equipment, lowering maintenance costs and improving overall operational efficiency.

Conclusion

Dry ice blasting is a modern, efficient, and environmentally responsible cleaning solution. Its non-abrasive, chemical-free, and residue-free process ensures industrial equipment stays clean, safe, and operational.

For professional and reliable dry ice blasting services, trust Top Dry Ice — your expert partner for eco-friendly, high-performance industrial cleaning solutions.

Categorieën

Read More

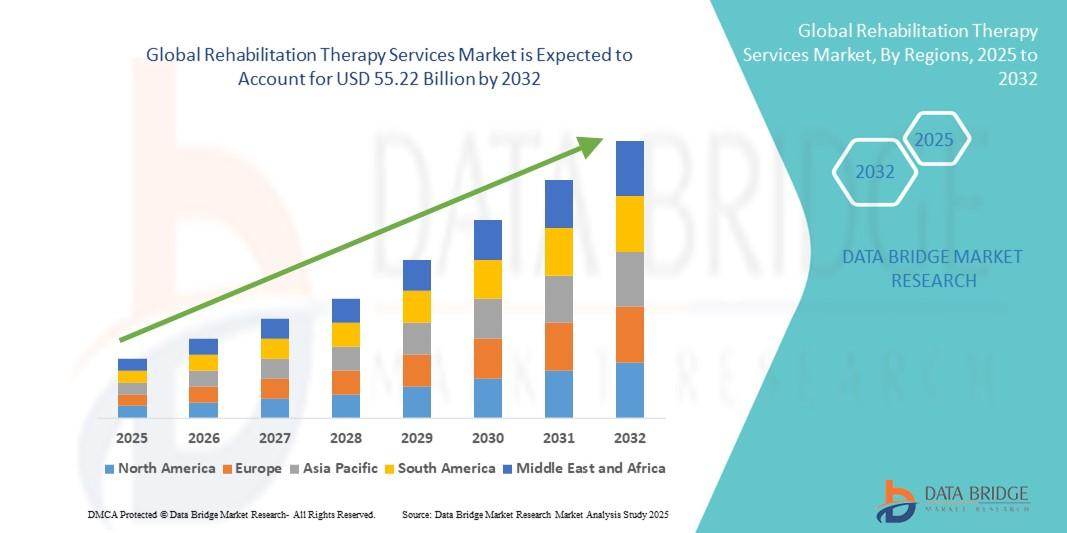

"Executive Summary Biological Buffers Market Opportunities by Size and Share CAGR Value Data Bridge Market Research analyzes that the global biological buffers market is expected to reach USD 1,850.91 million by 2035 from USD 837.07 million in 2024, growing at a substantial CAGR of 7.5% in the forecast period of 2025 to 2035 To achieve detailed market insights and keep market place...

Modern workshops rely on CNC machines, but performance depends on the right cnc tool, holders, and inserts for accurate cutting, low waste, and better results. What Is a CNC Tool and Why Is It Important? A CNC tool is a cutting or shaping part that is fixed to a CNC machine to remove material from a workpiece. It works based on programmed commands, so every cut is accurate and...

In high-efficiency converting and slitting operations, tension consistency is critical—and the Differential Shaft developed by cbbmachine offers a precise, adaptable solution for ensuring flawless winding across multiple cores in a single pass. This innovative shaft design solves the common issue of uneven web tension, which can lead to telescoping, wrinkling, or core...

Interest in cognitive enhancers has grown rapidly, and one of the most searched terms today is Buy Modafinil UK. Modafinil is widely known for promoting wakefulness and improving focus, making it popular among professionals, students, and shift workers. However, before considering Modafinil in the UK, it is important to understand how it works, its legal status, and safe purchasing options....

Co-op Dungeon Experience Duet Night Abyss offers a cooperative multiplayer mode focused on dungeon content, allowing players to team up for various challenges. While the main storyline and world exploration are primarily designed for solo play, the game provides solid co-op support within specific areas. In particular, players can join forces in dungeons to clear encounters and farm valuable...