How Dry Ice Blasting Provides a Faster and Cleaner Solution for Industrial Maintenance

How Dry Ice Blasting Provides a Faster and Cleaner Solution for Industrial Maintenance

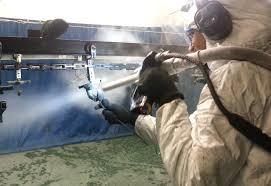

Dry Ice Blasting is an advanced cleaning technology that is transforming industrial maintenance. Unlike traditional methods that rely on water, chemicals, or abrasive materials, dry ice blasting uses solid CO₂ pellets accelerated at high speed. Upon impact, these pellets sublimate—turning from solid to gas—removing grease, paint, oil, and other contaminants without leaving residue or moisture. This method is safe, efficient, and environmentally friendly, making it ideal for delicate machinery and high-value equipment.

How Dry Ice Blasting Works

Dry ice blasting cleans surfaces through a combination of three effects:

-

Impact: High-speed pellets strike contaminants, breaking them free from the surface.

-

Thermal Shock: Extreme cold causes grime and residues to contract, loosening adhesion.

-

Sublimation: The dry ice vaporizes instantly, expanding and lifting debris without creating secondary waste.

This process ensures a deep, effective clean while preserving the integrity of sensitive equipment.

Benefits of Dry Ice Blasting

-

Non-Abrasive: Safe for metals, plastics, electronics, and coatings.

-

Residue-Free: No water, sand, or chemical residue is left behind.

-

Chemical-Free: Reduces exposure to hazardous cleaning agents.

-

Reduced Downtime: Equipment can often be cleaned in place without disassembly.

-

Eco-Friendly: Uses recycled CO₂ and minimizes environmental impact.

Applications in Various Industries

Manufacturing

Removes grease, oils, adhesives, and residues from molds, presses, and conveyor systems while production continues.

Food and Beverage

Sanitizes processing lines safely and efficiently, maintaining compliance with FDA and USDA standards.

Automotive and Aerospace

Cleans engines, molds, tools, and components without harming surfaces or precision parts.

Electrical and Power Systems

Non-conductive dry ice allows safe cleaning of transformers, turbines, and control panels.

Environmental and Workplace Advantages

Dry ice blasting eliminates chemical waste, reduces water usage, and minimizes operator exposure to hazardous substances. Its residue-free, dry cleaning process also prevents corrosion and extends the lifespan of equipment, lowering maintenance costs and improving overall operational efficiency.

Conclusion

Dry ice blasting is a modern, efficient, and environmentally responsible cleaning solution. Its non-abrasive, chemical-free, and residue-free process ensures industrial equipment stays clean, safe, and operational.

For professional and reliable dry ice blasting services, trust Top Dry Ice — your expert partner for eco-friendly, high-performance industrial cleaning solutions.

Категории

Больше

India, Pune – A recent report by The Insight Partners, titled “B2B Telecommunication Market Share, Size, Trends, and Forecast by 2031, The B2B Telecommunication market stands as a critical pillar supporting the interconnected global economy, transforming how enterprises communicate, collaborate, and compete. As businesses expand across borders, embracing digital...

The scale of metal recycling operations has increased significantly as industries seek reliable and cost-efficient raw material alternatives. Recycling offers economic advantages by lowering production costs while conserving natural resources. According to a recent report by Market Research Future, the Metal Recycling Market is witnessing steady expansion supported by rising industrial output...

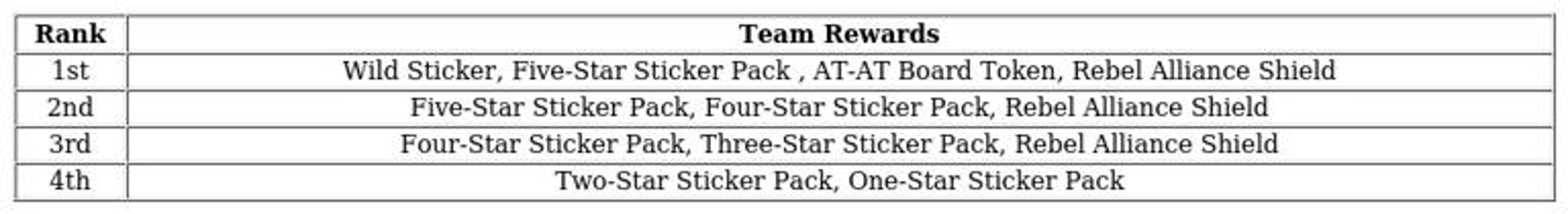

The Rebel Racers mini-game has been a thrilling addition to Monopoly GO!, with the event starting on June 12 and featuring intense team battles across three rounds. Success in these races rewards players with exciting prizes, including the coveted wild sticker, a 5-star sticker pack, and other exclusive items. This special event is scheduled to conclude on June 15, giving players a limited...

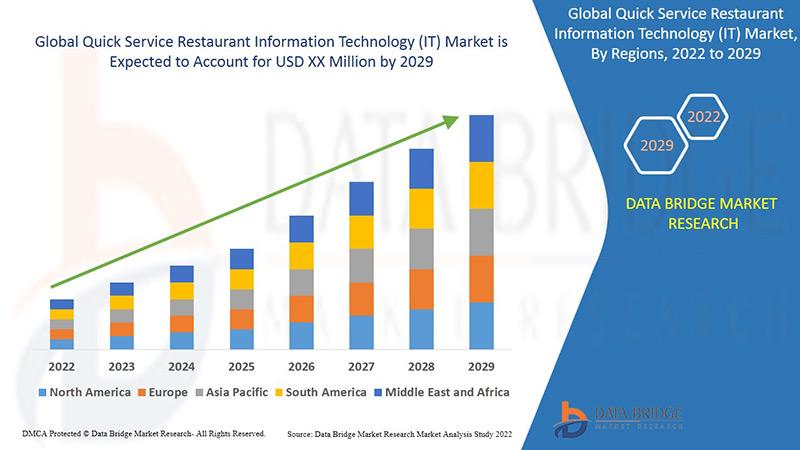

"Executive Summary Quick Service Restaurant Information Technology IT Market Opportunities by Size and Share CAGR Value Data Bridge Market Research analyses that the quick service restaurant information technology (IT) market will exhibit a CAGR of 5.10% for the forecast period of 2022-2029. Quick Service Restaurant Information Technology IT Market research report is a verified...

The handheld laser welder machine has emerged as a game-changer for professionals seeking high-quality welding without the constraints of bulky equipment. Whether in jewelry making, automotive repair, or industrial applications, this innovative tool is redefining the way metalwork is performed. What Makes a Handheld Laser Welder Machine Stand Out? Unlike traditional welding methods,...