Magnetic Separator Manufacturers for Industrial & Commercial Use

In today’s fast-moving industrial and commercial environment, maintaining product quality, equipment safety, and operational efficiency is more important than ever. One small piece of unwanted metal can damage machinery, contaminate products, and cause costly downtime. This is where magnetic separator manufacturers play a crucial role by providing reliable solutions that remove ferrous contaminants from raw materials and finished products.

From food processing plants to mining sites and recycling facilities, magnetic separation has become a basic yet powerful requirement. This article explains how magnetic separators work, why they matter, and how choosing the right manufacturer can make a real difference to your business.

What Is a Magnetic Separator?

A magnetic separator is a device designed to attract and remove unwanted iron particles from materials. These particles may be present in powders, granules, liquids, or bulk materials. The separator uses a magnetic field to pull out ferrous contaminants before they cause harm.

Industries rely on magnetic separator manufacturers to design equipment that fits specific processes, material flow, and safety standards. The right separator ensures smooth operations without interrupting production.

Why Magnetic Separation Is Important in Industries

Metal contamination is a common issue across many sectors. Even small iron particles can lead to serious problems such as equipment wear, product rejection, and safety risks. Magnetic separation helps prevent these issues at an early stage.

Key benefits include:

-

Protection of machines from damage

-

Improved product quality and purity

-

Reduced maintenance and downtime

-

Compliance with industry safety standards

Because of these advantages, industries depend heavily on experienced magnetic separator producers for consistent performance.

Industrial Applications of Magnetic Separators

-

Manufacturing & Engineering

In manufacturing units, magnetic separators are used to protect CNC machines, grinders, and processing equipment from metal damage. They also help maintain smooth production flow.

-

Mining & Minerals

Mining operations deal with large volumes of raw material. Separators help remove unwanted iron content before further processing, improving efficiency and reducing wear on crushers and conveyors.

-

Food & Pharma Industry

Product purity is critical in food and pharmaceutical industries. Magnetic separators ensure that metal contamination does not reach the final product, supporting hygiene and safety standards.

-

Recycling & Waste Management

Recycling plants use magnetic separators to separate ferrous metals from waste streams, making recycling more effective and profitable.

Each of these sectors relies on Magnetic Separator Manufacturers who understand industry-specific challenges.

Commercial Uses of Magnetic Separators

Beyond heavy industries, magnetic separators are widely used in commercial settings such as warehouses, material handling units, and packaging lines. They help maintain cleanliness, prevent damage during handling, and ensure smooth logistics operations.

Commercial buyers often look for compact, easy-to-install systems from trusted magnetic separator manufacturers that require minimal maintenance.

Types of Magnetic Separators Available

Different applications require different designs. Common types include

-

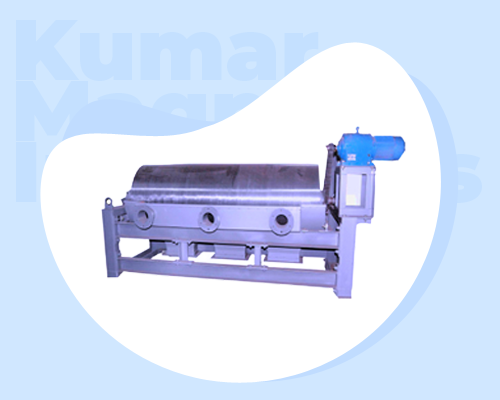

Drum Magnetic Separators – Suitable for bulk material handling

-

Overband Magnetic Separators—Used on conveyor belts

-

Magnetic Grid Separators—Best for cleaning fine powders and small-sized materials.

-

Liquid Line Magnetic Separators—Used in liquid processing systems

Reliable magnetic separator manufacturers offer guidance to help businesses select the right type based on material flow and contamination level.

How to Choose the Right Magnetic Separator Manufacturer

Choosing the right manufacturer is very important for the selection of a good magnetic separator. Here are some key factors to consider:

-

Industry Experience

Manufacturers with long-term experience understand real-world challenges and offer practical solutions.

-

Quality Standards

High-quality magnets, strong housing, and proper testing ensure a long service life.

-

Customization Options

Every industry has different needs. A good manufacturer offers customized solutions rather than one-size-fits-all products.

-

After-Sales Support

Installation guidance, maintenance support, and quick service response add long-term value.

Working with trusted magnetic separator manufacturers ensures your investment delivers consistent results.

Innovation and Technology in Magnetic Separation

Modern magnetic separators are more efficient, compact, and powerful than ever before. Advances in magnetic strength and design allow better separation with lower energy use.

Leading magnetic separator manufacturers focus on innovation to improve performance, reduce maintenance needs, and support sustainable operations.

Trusted Name in Magnetic Solutions

Among the well-established names in the magnetic separation industry, Kumar Magnet is widely recognized for providing reliable and efficient magnetic separation solutions for both industrial and commercial applications. As one of the trusted Magnetic Drum Separator Manufacturers, the company emphasizes product quality, precise engineering, and customer-focused solutions to meet diverse operational needs. Its consistent performance standards and attention to detail have helped build strong trust across multiple industries. Businesses that prioritize long-term operational efficiency and equipment safety often prefer working with suppliers that demonstrate proven expertise, dependable product quality, and a strong industry reputation, ensuring smooth processes and reduced maintenance concerns over time.

The Role of Magnetic Separators in Cost Savings

Many businesses view magnetic separators as a safety tool, but they are also a cost-saving investment. By preventing machine damage and reducing downtime, they lower maintenance expenses and extend equipment life.

Experienced magnetic separator manufacturers help companies achieve these savings by recommending the right system for each application.

Future of Magnetic Separation in Industry

As industries grow more automated, the demand for efficient contamination control will increase. Magnetic separators will continue to evolve with smarter designs and stronger materials.Companies that partner with forward-thinking magnetic separator manufacturers will be better prepared to meet future quality and safety requirements.

Final Thoughts

Magnetic separators may look simple, but their impact on industrial and commercial operations is significant. From protecting equipment to ensuring product purity, they are a critical part of modern production systems. Choosing reliable magnetic separator manufacturers means choosing safety, efficiency, and long-term value for your business.

If you are planning to upgrade your contamination control system or install a new magnetic separator, now is the right time to consult experienced professionals. Partner with Kumar Magnet to get the right solution tailored to your industry needs and ensure smooth, trouble-free operations for years to come.