Introduction to GMP Certification

Introduction to GMP Certification

GMP certification refers to Good Manufacturing Practice, a globally recognized system that ensures products are consistently produced and controlled according to quality standards. It is especially crucial in industries such as pharmaceuticals, food, cosmetics, and medical devices, where safety and quality directly impact consumer health. GMP certification demonstrates that an organization follows strict manufacturing processes, hygiene practices, documentation procedures, and quality control systems that meet regulatory expectations and international benchmarks.

Importance of GMP Certification for Businesses

GMP certification plays a vital role in building trust among customers, regulators, and stakeholders. It assures that products are manufactured in a clean, controlled, and well-monitored environment, minimizing risks of contamination, errors, and defects. Organizations certified under GMP gain a competitive advantage in both local and international markets. Regulatory bodies such as the World Health Organization and the Food and Drug Administration emphasize GMP compliance as a key requirement for product safety and quality assurance.

Key Requirements of GMP Certification

To achieve GMP certification, companies must implement structured procedures covering personnel training, equipment maintenance, sanitation, documentation, and quality assurance. Proper facility design, validated processes, and consistent record-keeping are essential components of compliance. Organizations must also establish Standard Operating Procedures (SOPs) and ensure traceability throughout the production cycle. Regular internal audits and risk assessments help maintain ongoing compliance and continuous improvement.

GMP Certification Process

The GMP certification process typically begins with a gap analysis to identify areas that need improvement. This is followed by the development of quality management systems and staff training. Once the organization is prepared, an external certification body conducts an audit to evaluate compliance with GMP standards. If the company meets all requirements, certification is granted. Periodic surveillance audits are conducted to ensure ongoing adherence to GMP guidelines and regulatory standards.

Benefits of GMP Certification

GMP certification offers numerous benefits, including enhanced product quality, improved operational efficiency, and reduced risk of recalls or regulatory penalties. It strengthens brand reputation and increases customer confidence by demonstrating a commitment to safety and consistency. Additionally, it facilitates smoother entry into global markets, as many international buyers and regulators require GMP compliance before approving suppliers or products.

Industries That Require GMP Certification

Several industries rely heavily on GMP certification, including pharmaceuticals, food processing, nutraceuticals, cosmetics, and biotechnology. In these sectors, maintaining product integrity and safety is critical, making GMP a fundamental requirement rather than an optional standard. By implementing GMP practices, organizations ensure regulatory compliance while delivering high-quality products that meet consumer and market expectations.

Categorias

Leia Mais

In today’s digital-first world, having a strong online presence is no longer optional—it is a necessity. Businesses of all sizes are investing in professional websites to attract customers, build credibility, and increase sales. Website Development In Ahmedabad has seen massive growth due to the city’s booming IT ecosystem, skilled developers, and cost-effective solutions....

In modern industries, precision and efficiency in cleaning processes are no longer optional; they are critical to maintaining quality, productivity, and safety. The laser cleaner machine has emerged as a transformative solution, offering a method of cleaning surfaces that is both effective and environmentally considerate. Unlike traditional cleaning methods, which often rely on harsh chemicals,...

"What’s Fueling Executive Summary Butyl Acetate Market Size and Share Growth CAGR Value The global butyl acetate market size was valued at USD 2.88 billion in 2024 and is expected to reach USD 3.77 billion by 2032, at a CAGR of 3.4% during the forecast period An influential Butyl Acetate Market document supports in achieving a sustainable growth in...

Shot peening has long been a cornerstone process for improving fatigue life, stress resistance, and surface durability of metal components across aerospace, automotive, energy, and heavy industries. While the core principle — bombarding a surface with small spherical media to induce compressive residual stresses — remains unchanged, the last decade has delivered a wave of...

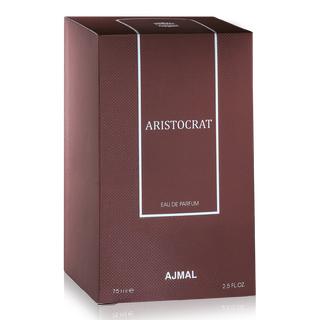

Finding authentic Ajmal Perfumes in Kuwait doesn’t have to be a challenge. Whether you’re looking for a signature scent, a luxurious gift, or a traditional aroma, knowing where to explore options like attar Kuwait and bakhoor can make all the difference. With the right guidance, discovering your favorite Ajmal fragrance becomes a seamless and enjoyable experience. Why Ajmal Perfumes...